Preparation method of calcium folinate

A technology of calcium folinate and methylenetetrahydrofolate, which is applied in the direction of organic chemistry, can solve the problems of multiple impurities, high temperature, and easy production, and achieve the effect of reducing reaction temperature, shortening time, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The specific embodiment of the present invention provides a kind of preparation method of calcium folinate, comprising the following steps:

[0040] (1) Reduction of folic acid to tetrahydrofolic acid: first dissolve folic acid in an alkaline solution, then slowly add sodium borohydride solution, react at 60-90 °C for 1-3 hours, then cool down to 0-10 °C, and then use concentrated hydrochloric acid The pH is adjusted to 3-5 to obtain an off-white solid, which is filtered with suction to obtain a solid of tetrahydrofolic acid, and the molar ratio of the folic acid to sodium borohydride is 1:8-12.

[0041] (2) Formylation of tetrahydrofolate to obtain 5,10-methylenetetrahydrofolate hydrochloride: first dissolve tetrahydrofolate in an acidic solution, and then add methyl formate and tetrahydrofolate at 20-25°C. Hydrofolate was reacted for 1-2 hours, then the temperature was raised to 55-65°C, and formic acid and trifluoroacetic acid were added to continue the reaction for ...

Embodiment 1

[0045] Embodiment 1 A kind of preparation method of calcium folinate, comprising:

[0046] (1) reduction of folic acid to tetrahydrofolate: put 30g of folic acid and 200g of water into a 1000ml four-necked bottle, stir evenly, add 30g of 18% sodium hydroxide solution to completely dissolve the folic acid; then add 30g of sodium borohydride to 100g In water, stir evenly, slowly add it into the folic acid system with a constant pressure dropping funnel, then heat up to 60 °C, react for 2 h, then cool down to 0-10 °C, adjust the pH to 3-5 with concentrated hydrochloric acid, and obtain off-white solid, Suction filtration to obtain 32 g of solid tetrahydrofolate.

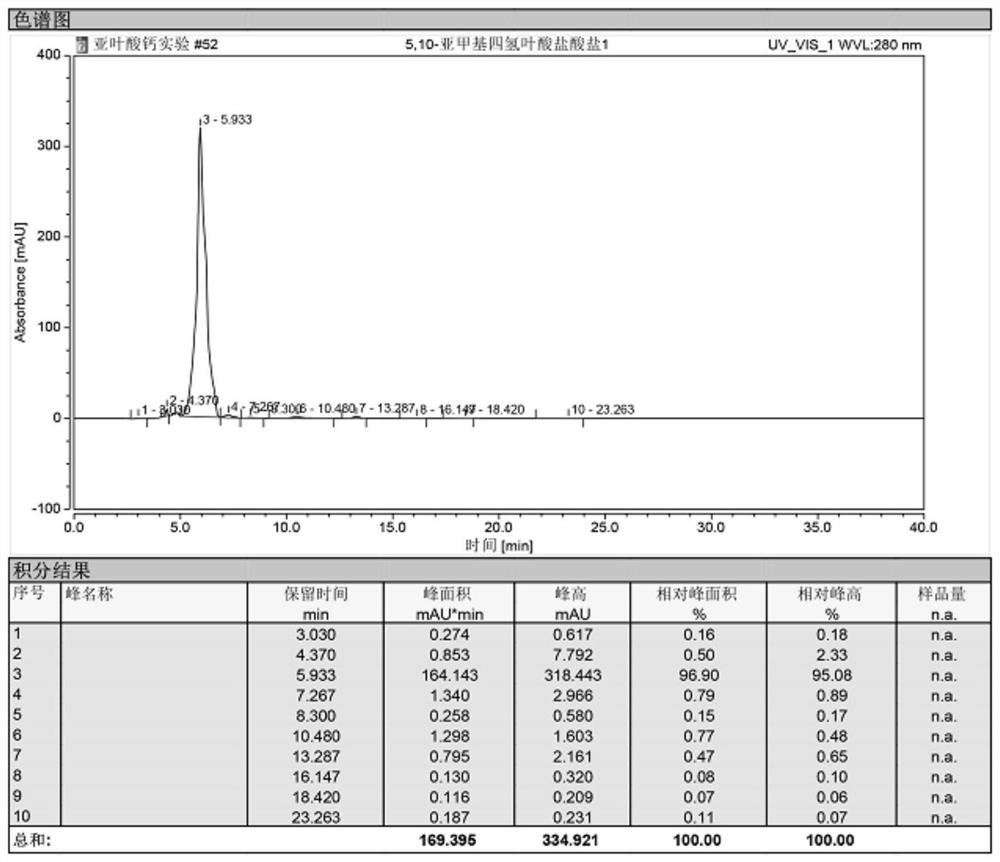

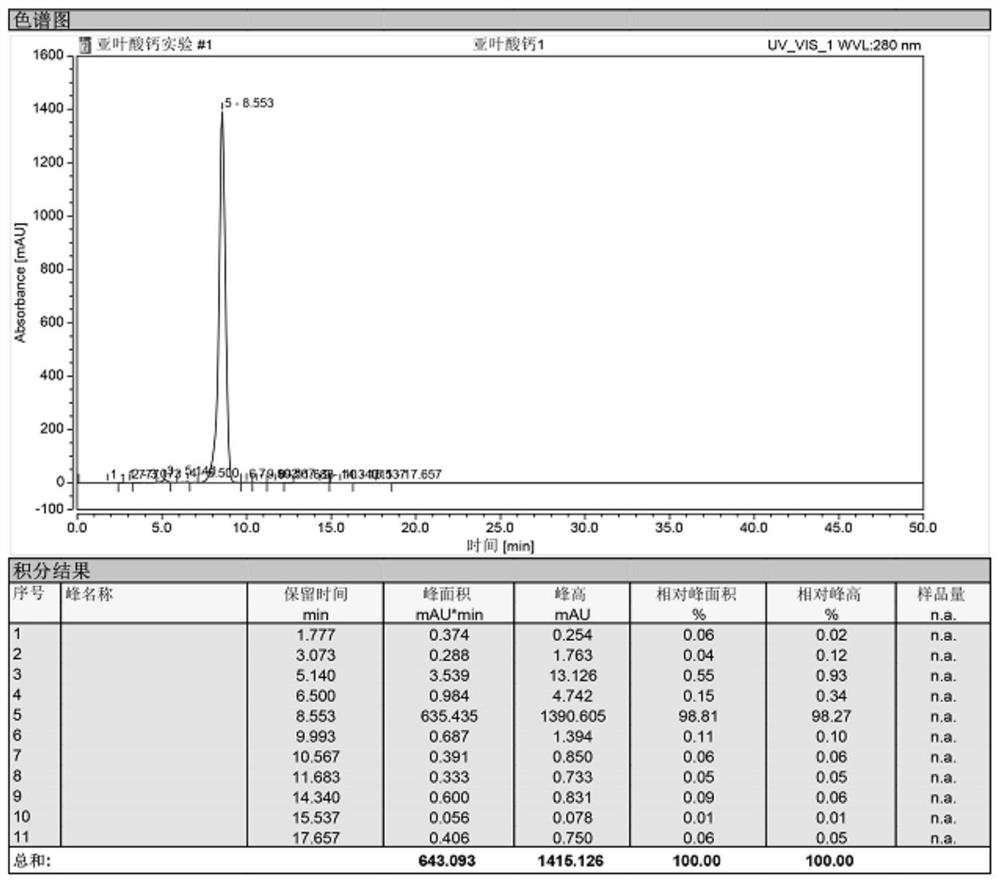

[0047] (2) Formylation of tetrahydrofolate to obtain 5,10-methylenetetrahydrofolate hydrochloride: add the solid tetrahydrofolate obtained in step 1 into 70 g of water, and adjust the pH to about 1 with dilute hydrochloric acid to completely dissolve , add 2.6 g of methyl formate (content ≥ 95%, density 0.974 g / mL), re...

Embodiment 2

[0050] Embodiment 2 A kind of preparation method of calcium folinate, comprising:

[0051] (1) reduction of folic acid to tetrahydrofolate: put 30g of folic acid and 200g of water into a 1000ml four-necked bottle, stir evenly, add 30g of 18% sodium hydroxide solution to completely dissolve the folic acid; then add 30g of sodium borohydride to 100g In water, stir evenly, slowly add it into the folic acid system with a constant pressure dropping funnel, then heat up to 60 °C, react for 2 h, then cool down to 0-10 °C, adjust the pH to 3-5 with concentrated hydrochloric acid, and obtain off-white solid, Suction filtration to obtain 33 g of solid tetrahydrofolate.

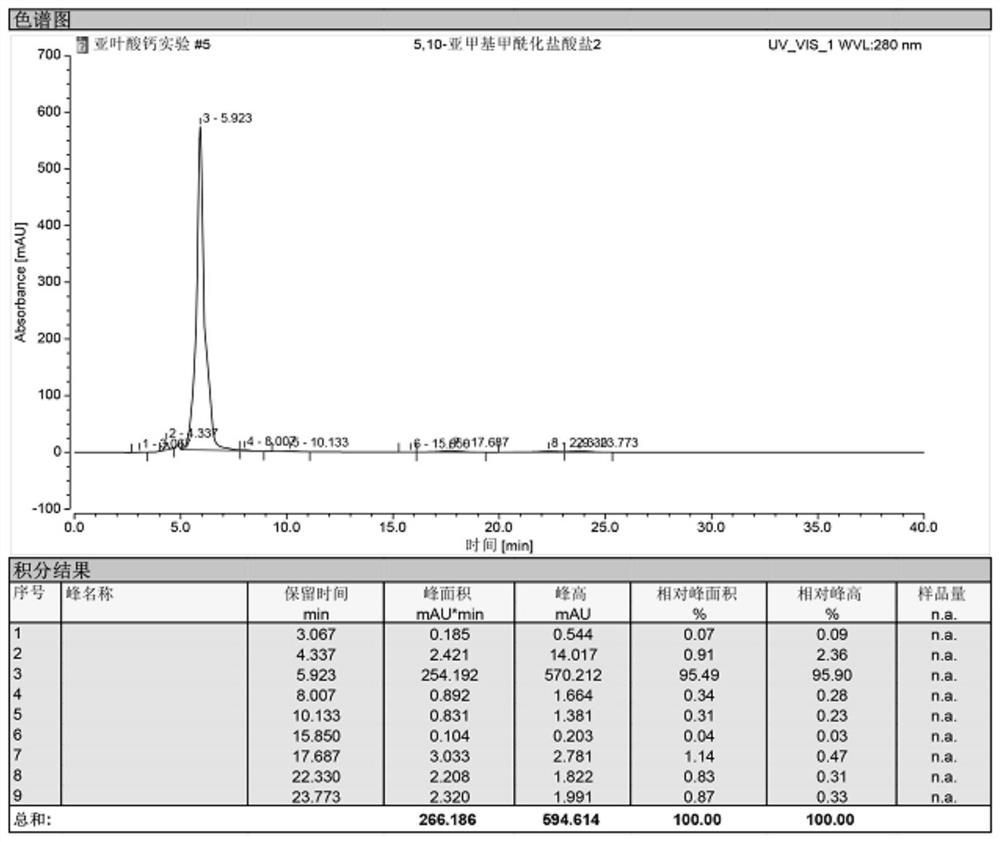

[0052] (2) Formylation of tetrahydrofolate to obtain 5,10-methylenetetrahydrofolate hydrochloride: add the solid tetrahydrofolate obtained in step 1 into 70 g of water, and adjust the pH to about 1 with dilute hydrochloric acid to completely dissolve , add 3.0 g of methyl formate (content ≥ 95%, density 0.974 g / mL), re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com