Polyimide composite foam material with photocatalytic performance as well as preparation method and application thereof

A technology of syntactic foam and polyimide, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalyst, special compound water treatment, etc., can solve the problem of low utilization of sunlight, inconvenient recycling, It can solve problems such as long processing cycle, and achieve the effect of being beneficial to recycling, improving utilization rate and improving effective separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

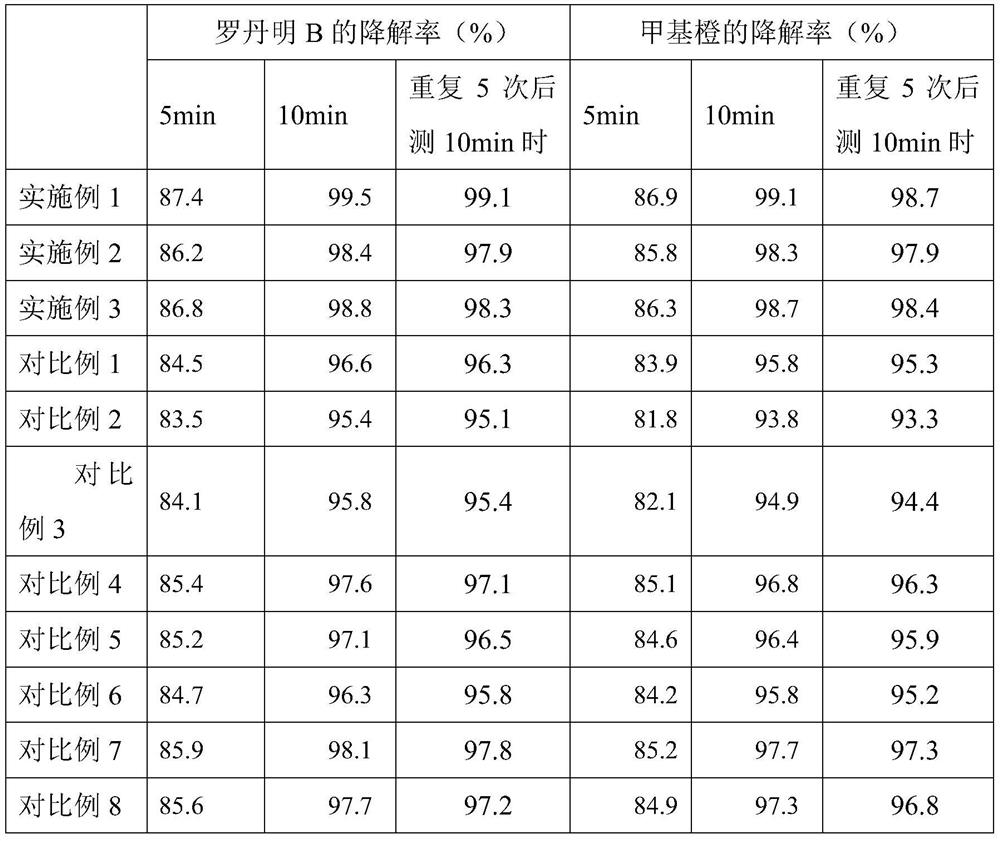

Examples

Embodiment 1

[0039] A preparation method of a polyimide composite foam material with photocatalytic performance, comprising the following:

[0040] (I) Preparation of Y-Mn co-doped g-C 3 N 4 ;

[0041] a) Add 0.01 mol of yttrium nitrate and 0.045 mol of manganese nitrate to 50 mL of distilled water, then add 1 mol of melamine, stir magnetically for 30 min at 80 °C, and then ultrasonically treat for 30 min to obtain a mixed solution, which is dried at 110 °C for 13 hours to obtain a precursor;

[0042] b) Grind the precursor, calcined at 550°C for 4h in a nitrogen atmosphere, and the heating rate of the calcination is 4°C / min to obtain the target product Y-Mn / g-C 3 N 4 photocatalytic materials;

[0043] (II) Preparation of Ce-Co Co-doped Cu 3 P

[0044] (1) get 1mol copper nitrate, 0.02mol cerium nitrate, 0.03mol cobalt nitrate, 4mol yellow phosphorus and 0.3g sodium dodecylbenzene sulfonate and dissolve in 100mL deionized water successively, stir to make it evenly mixed;

[0045] (2...

Embodiment 2

[0050] A preparation method of a polyimide composite foam material with photocatalytic performance, comprising the following:

[0051] (I) Preparation of Y-Mn co-doped g-C 3 N 4 ;

[0052] a) Add 0.015mol of yttrium acetate and 0.015mol of manganese chloride into 50mL of distilled water, then add 1mol of melamine, stir magnetically at 90°C for 20min, then ultrasonically treat for 20min to obtain a mixed solution, and dry at 120°C for 12h to obtain a precursor ;

[0053] b) Grinding the precursor, calcining at 600°C for 3h in a nitrogen atmosphere, the heating rate of the calcination is 6°C / min, to obtain the target product Y-Mn / g-C 3 N 4 photocatalytic materials;

[0054] (II) Preparation of Ce-Co Co-doped Cu 3 P

[0055] (1) get 1mol copper acetate, 0.03mol cerium chloride, 0.02mol cobalt acetate, 6 yellow phosphorus and 0.4g cetyl trimethyl ammonium bromide and dissolve successively in the deionized water of 100mL, stir to make it mix uniformly;

[0056] (2) Transfer...

Embodiment 3

[0061] A preparation method of a polyimide composite foam material with photocatalytic performance, comprising the following:

[0062] (I) Preparation of Y-Mn co-doped g-C 3 N 4 ;

[0063] a) Add 0.005mol of yttrium nitrate and 0.075mol of manganese acetate into 50mL of distilled water, then add 1mol of melamine, stir magnetically for 40min at 70°C, then ultrasonically treat for 40min to obtain a mixed solution, and dry at 100°C for 14h to obtain a precursor;

[0064] b) Grinding the precursor, calcining at 500°C for 5h in a nitrogen atmosphere, the heating rate of the calcination is 3°C / min, to obtain the target product Y-Mn / g-C 3 N 4 photocatalytic materials;

[0065] (II) Preparation of Ce-Co Co-doped Cu 3 P

[0066] (1) get 1mol cupric chloride, 0.01mol cerium chloride, 0.04 cobalt nitrate, 3mol yellow phosphorus and 0.1g sodium dodecylbenzene sulfonate and dissolve in a certain amount of 100mL deionized water successively, stir to make it evenly mixed;

[0067] (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com