Efficient scale and corrosion inhibitor for circulating water and preparation method of efficient scale and corrosion inhibitor

A scale and corrosion inhibitor, circulating water technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Secondary pollution, poor stability and other problems, achieve a small amount of high-efficiency scale and corrosion inhibition performance, prolong the service life of equipment, and excellent corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

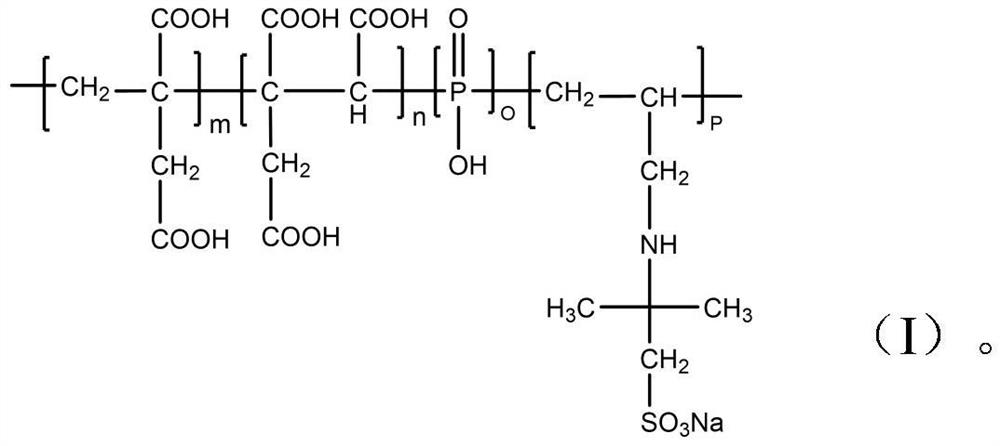

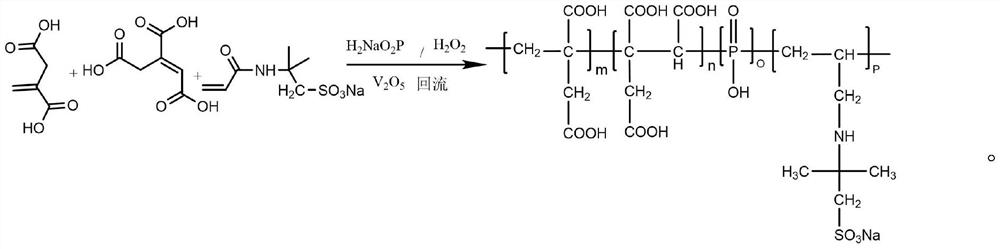

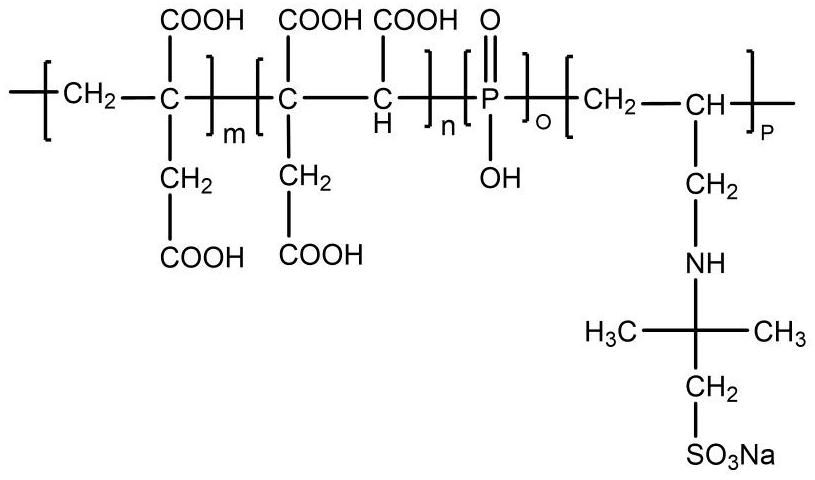

[0038] Preparation of polycarboxylate sulfonate tetrapolymer:

[0039] S1: Add 183Kg of itaconic acid, 216.5Kg of aconitic acid, 3.1Kg of dodecyl mercaptan, 0.5Kg of vanadium pentoxide, and 220Kg of deionized water into the reaction kettle in sequence, start stirring, heat up to 45°C, and dissolve Add 23.6Kg sodium hypophosphite, continue to stir and dissolve;

[0040] S2: After dissolving, heat up to 70°C, and at the same time slowly add 327Kg hydrogen peroxide and 174Kg 58.6wt% 2-acryloyl-2-methylpropanesulfonate aqueous solution, drop slowly for 4.5h, and control the dropping temperature at 95-98 ℃;

[0041] S3: Keep warm at 106-112°C for 3.0h after the dropwise addition;

[0042] S4: lower the temperature to below 50° C., and filter to obtain a brown-red polycarboxylate sulfonate tetrapolymer solution with a solid content of 48.26% and a number average molecular weight of 2750.

Embodiment 2

[0044] Preparation of polycarboxylate sulfonate tetrapolymer:

[0045] S1: Add 176Kg of itaconic acid, 225Kg of aconitic acid, 2.83Kg of dodecyl mercaptan, 0.5Kg of vanadium pentoxide, and 220Kg of deionized water into the reactor in sequence, start stirring, and heat up to 45°C to dissolve;

[0046] S2: Inhale 332.7Kg of hydrogen peroxide into the head tank 1;

[0047] S3: Dissolve 97Kg of sodium 2-acryloyl-2-methylpropanesulfonate in 75Kg of deionized water, and suck it into the head tank 2;

[0048] S4: Open the manhole of the reaction kettle, put 25.3Kg of sodium hypophosphite into the reaction kettle and continue to stir and dissolve;

[0049] S5: After the dissolution in the reaction kettle is completed, the temperature is raised to 70°C, and the drop valves of high-level tank 1 and high-level tank 2 are opened at the same time, and the dropwise addition is performed slowly for 6 hours, and the dropping temperature is controlled at 95-98°C;

[0050] S6: Keep warm at 10...

Embodiment 3

[0053] Preparation of a high-efficiency scale and corrosion inhibitor for circulating water:

[0054] S1: Weigh 40Kg polycarboxylate sulfonate tetrapolymer P1, 25Kg adsorption polymer corrosion inhibitor, 20Kg S-carboxyethyl thiosuccinic acid, 5Kg methyl benzotriazole, 10Kg polyepoxy Sodium succinate, 5Kg deionized water;

[0055] S2: Add the above-mentioned polycarboxylate sulfonate tetrapolymer, adsorptive polymer corrosion inhibitor, S-carboxyethylsulfosuccinic acid, polycarboxylic acid and its salt into the reaction kettle in sequence, and stir at room temperature for 25 minutes ;

[0056] S3: Add azole derivatives into the reaction kettle, raise the temperature to 40°C, and stir for 20 minutes;

[0057] S4: Add deionized water into the reaction kettle, stir evenly at 35°C for 30 minutes, and filter to obtain a high-efficiency scale and corrosion inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com