Molybdenum-copper alloy heat sink ultrasonic-assisted diffusion bonding manufacturing method based on pulse current heating and diffusion welding device

A molybdenum-copper alloy, pulse current technology, applied in the field of optoelectronic packaging and electronics, can solve the problems of low interface bonding strength, high impact and noise by explosive composite method, low atomic diffusion rate, etc., to achieve uniformity of the organization. , the effect of accelerating interfacial atomic bonding and increasing atomic diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

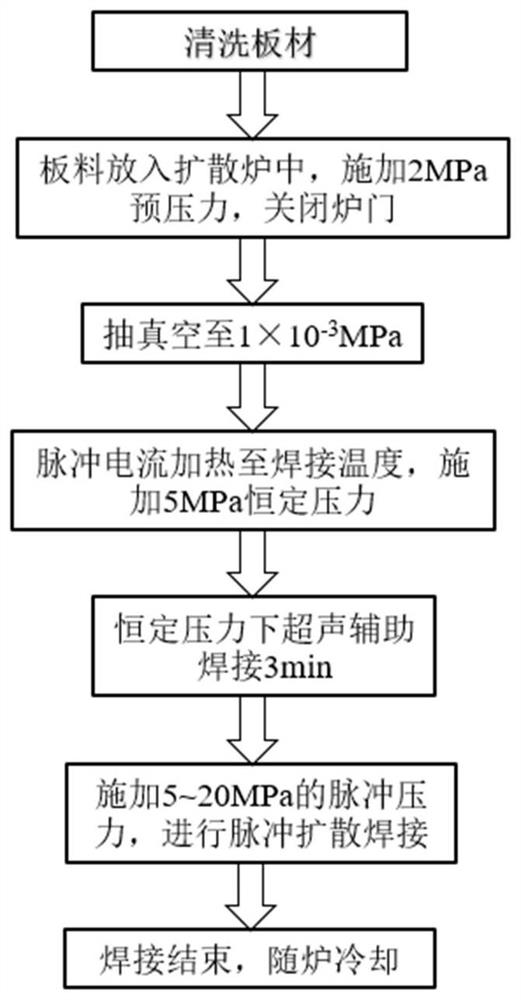

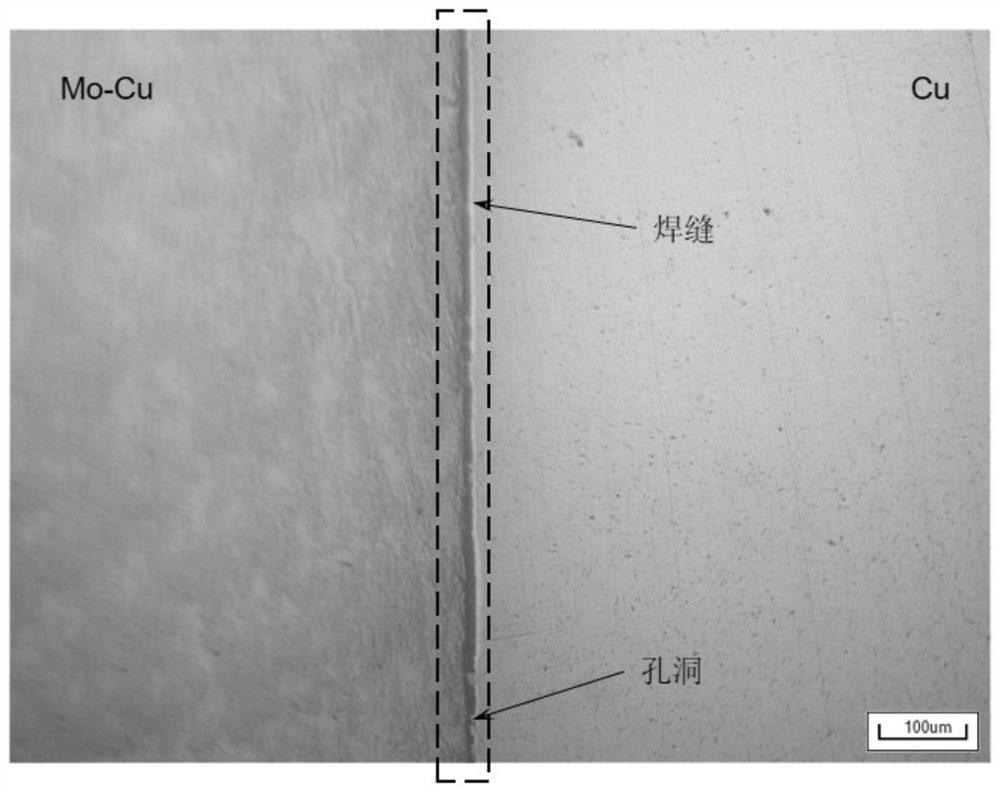

[0038] Using pulse current heating, ultrasonic vibration is applied to realize the connection of molybdenum copper alloy and copper during the welding process. The process conditions of diffusion bonding are as follows: welding temperature is 760℃, pulse pressure is 5~15MPa, ultrasonic-assisted welding time is 3min, constant axis The pressure is 5MPa, the ultrasonic power is 800W, the ultrasonic amplitude is 5μm, the ultrasonic frequency is 25kHz, and the duty ratio of the pulse current is 12(on):2(off).

[0039] Step 1: The surfaces to be welded of the molybdenum-copper alloy and copper are polished with 800#, 1000# and 1200# sandpaper in turn to ensure smooth surface, then alkali cleaning, pickling, and ultrasonic cleaning in alcohol solution for 10min, placed in Dry in a drying oven for later use;

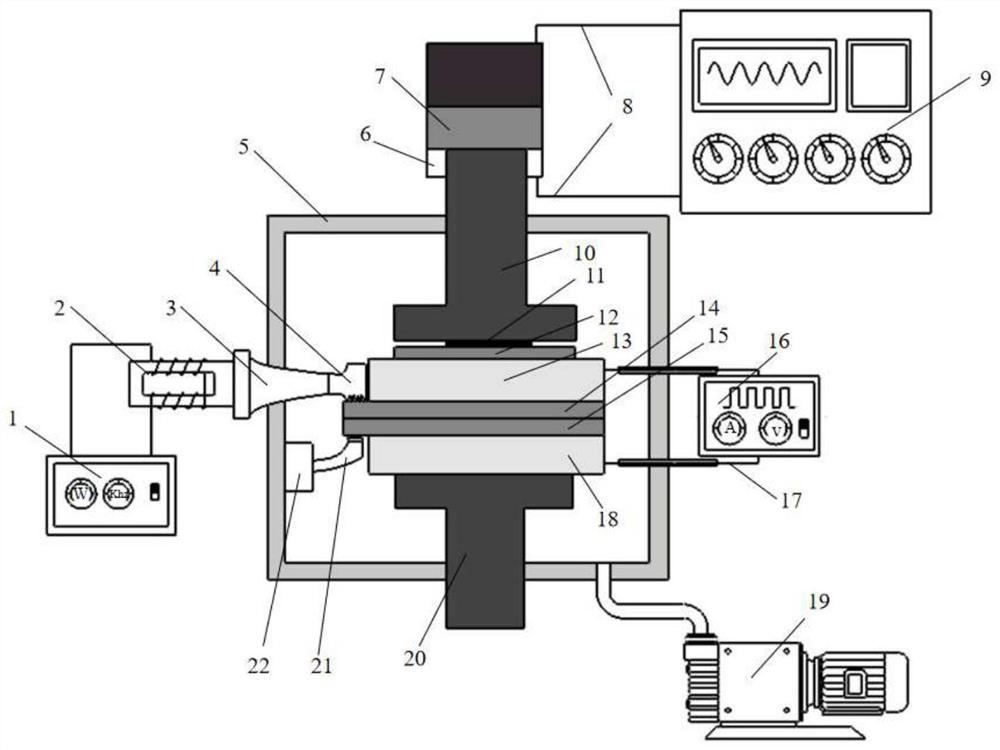

[0040] Step 2: Place the copper sheet obtained in step 1 on the upper surface of the lower electrode block of the pulse current plasma diffusion welding furnace, and place the mol...

Embodiment 2

[0052] The connection between molybdenum-copper alloy and copper is realized by applying pulse current heating and ultrasonic vibration during the welding process. The process conditions of diffusion bonding are as follows: welding temperature is 790℃, pulse pressure is 5~17.5MPa, ultrasonic-assisted welding time is 3min, constant The axial pressure is 5MPa, the ultrasonic power is 800W, the ultrasonic amplitude is 5μm, the ultrasonic frequency is 25kHz, and the pulse current duty ratio is 12(on):2(off).

[0053] Step 1: The surfaces to be welded of the molybdenum-copper alloy and copper are polished with 800#, 1000# and 1200# sandpaper in turn to ensure smooth surface, then alkali cleaning, pickling, and ultrasonic cleaning in alcohol solution for 10min, placed in Dry in a drying oven for later use;

[0054] Step 2: Place the copper sheet obtained in step 1 on the upper surface of the lower electrode block of the pulse current plasma diffusion welding furnace, and place the m...

Embodiment 3

[0062] The connection between molybdenum-copper alloy and copper is realized by applying pulse current heating and ultrasonic vibration during the welding process. The process conditions of diffusion bonding are as follows: welding temperature is 820℃, axial constant pulse pressure is 5MPa, ultrasonic-assisted welding time is 3min, pulsed The pressure is 5~20MPa, the ultrasonic power is 800W, the ultrasonic amplitude is 5μm, the ultrasonic frequency is 25kHz, and the pulse current duty ratio is 12(on):2(off).

[0063] Step 1: Use 800#, 1000# and 1200# sandpaper to polish the surface to be welded of molybdenum copper alloy and copper to ensure smooth surface, then carry out alkaline cleaning, acid cleaning, ultrasonic cleaning in alcohol solution for 10min, and put it to dry Drying in the oven for later use;

[0064] Step 2: Place the copper sheet obtained in step 1 on the upper surface of the lower electrode block of the pulse current plasma diffusion welding furnace, and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com