Method for preparing crystal nucleus early-strength polycarboxylate superplasticizer with long-term dispersity

A technology of strong polycarboxylic acid and water-reducing agent, applied in the field of water-reducing agent, can solve problems such as poor water-reducing effect, and achieve the effects of not easy to disperse, increase specific surface area, and improve reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

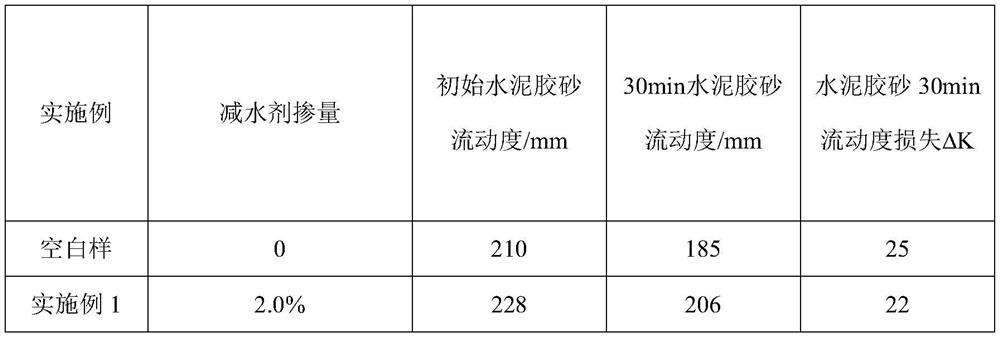

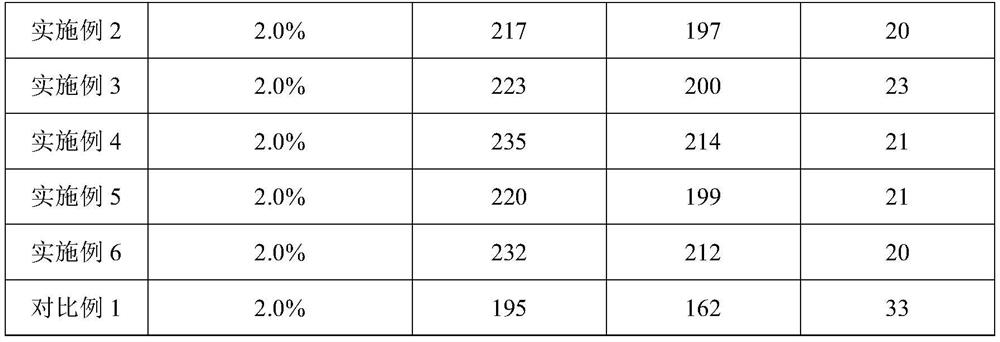

Examples

Embodiment 1

[0049] The method for preparing crystal nucleus early-strength polycarboxylate water-reducing agent in this embodiment comprises the following steps:

[0050] (1) take by weighing 23.0g (0.18mol) calcium formate, 77g distilled water and be placed in the beaker of 300ml, stir and dissolve completely under the action of magnetic stirrer, promptly be mixed with molar concentration and be the calcium formate aqueous solution of 2.3mol / L for subsequent use;

[0051] (2) Weigh 50g (0.18mol) of sodium metasilicate nonahydrate and 100g of water and place them in a 300ml beaker, stir and dissolve completely under the action of a magnetic stirrer, namely, be prepared into a sodium silicate with a molar concentration of 1.8mol / L Aqueous solution for standby;

[0052] (3) 13.46g of polyether macromonomer alkylene polyoxyethylene ether and 7.7g of water were placed in a 50mL beaker, heated and dissolved on a magnetic stirrer to obtain mixed solution 1; 0.065g of mercaptopropionic acid was ,...

Embodiment 2

[0056] The method for preparing crystal nucleus early-strength polycarboxylate water-reducing agent in this embodiment comprises the following steps:

[0057] (1) take by weighing 34.5g (0.26mol) calcium formate, 90.5g distilled water and place in the beaker of 300ml, stir and dissolve completely under the action of magnetic stirrer, promptly be mixed with molar concentration and be the calcium formate aqueous solution of 2.9mol / L for subsequent use;

[0058] (2) Weigh 75g (0.26mol) of sodium metasilicate nonahydrate and 100g of water and place them in a beaker of 300ml, stir and dissolve completely under the action of a magnetic stirrer, that is, prepare a sodium silicate with a molar concentration of 2.6mol / L Aqueous solution for standby;

[0059] (3) 11.22g of polyether macromonomer methylalkenyl polyoxyethylene ether (OXAB-608) and 6.4g of water were charged into a 50mL beaker, and heated and dissolved on a magnetic stirrer to obtain a mixed solution 1; 0.054g of mercapto...

Embodiment 3

[0063] The method for preparing crystal nucleus early-strength polycarboxylate water-reducing agent in this embodiment comprises the following steps:

[0064] (1) take by weighing 11.5g (0.09mol) calcium formate, 68.5g distilled water and place in the beaker of 300ml, stir and dissolve completely under the action of magnetic stirrer, promptly be mixed with molar concentration and be the calcium formate aqueous solution of 1.3mol / L for subsequent use;

[0065] (2) Weigh 25g (0.09mol) of sodium metasilicate nonahydrate and 100g of water and place them in a beaker of 300ml, stir and dissolve completely under the action of a magnetic stirrer, that is, prepare a sodium silicate with a molar concentration of 0.9mol / L Aqueous solution for standby;

[0066] (3) 15.7g of polyether macromonomer OXAB-608 and 8.97g of water were placed in a 50mL beaker, heated and dissolved on a magnetic stirrer to obtain mixed solution 1; 0.076g of mercaptopropionic acid, 0.031g of VC, 4.35 g water into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com