Negative electrode material, preparation method thereof and lithium ion battery

A negative electrode material and silicon-based material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of increasing irreversible reactions, low capacity retention rate of nanostructured silicon materials, high specific surface area of nano-silicon materials and aggravated interface side reactions, etc. problems, to achieve the effects of reducing irreversible consumption, improving cycle stability, and increasing capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

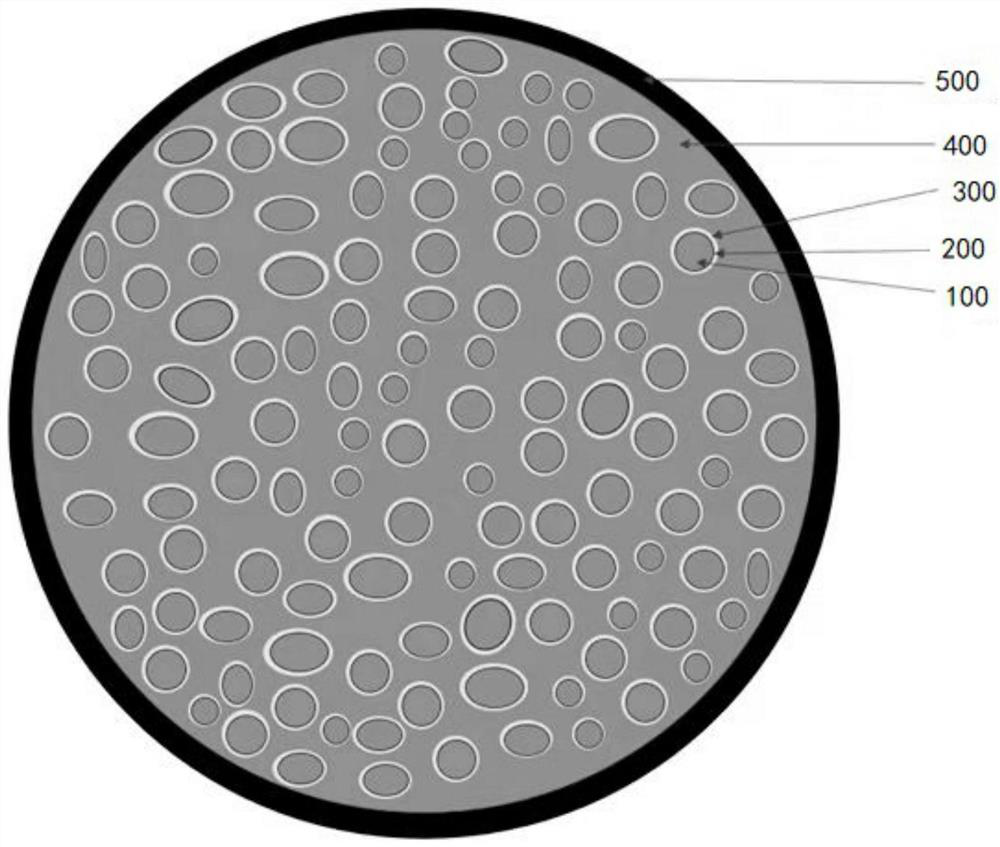

Image

Examples

preparation example Construction

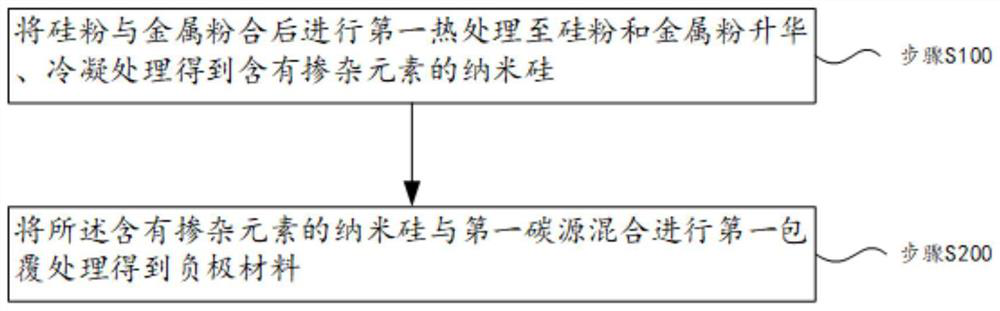

[0122] The present application also provides a method for preparing a negative electrode material, comprising the following steps:

[0123] In step S100, the silicon powder and the metal powder are mixed and then subjected to a first heat treatment until the silicon powder and the metal powder are sublimated and condensed to obtain nano-silicon containing doping elements.

[0124] Step S200 , performing a first coating treatment on the nano-silicon containing doping elements and the first carbon source to obtain a negative electrode material.

[0125] In the above technical solution, the present application obtains nano-silicon containing doping elements by first heat treatment until the sublimation of silicon powder and metal powder, and then condensation treatment, and the metal doping elements can be uniformly distributed in the crystal lattice of the nano-silicon, so that Nano-silicon can maintain a high reversible capacity, and can improve the conductivity of the silicon ma...

Embodiment 1

[0206] This embodiment provides a method for preparing a silicon carbon anode material, and the preparation steps include:

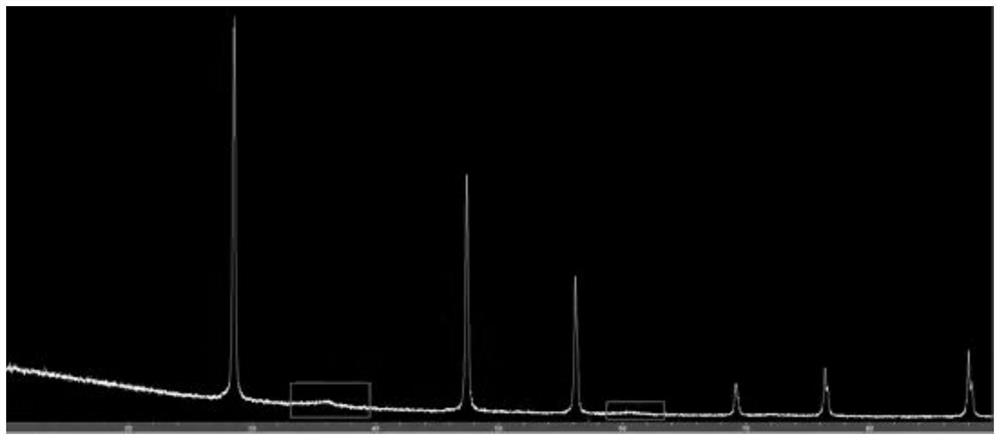

[0207] (1) Mix the elemental silicon powder and germanium powder with a mass ratio of 92:8 in a VC mixer at 120rpm for 10min, place in a vacuum high temperature furnace, evacuate to below 50Pa, heat to 1300°C, keep the temperature for 3 hours, and wait for the powder to evaporate completely After condensing to 300°C, the condensed germanium-doped nano-silicon is collected for use.

[0208] (2) Disperse 2g of dopamine hydrochloride in 2L of deionized water, continue stirring, add 0.02g of sodium hydroxide, then dropwise add tris hydrochloride solution to adjust the pH value to 8.5, then add 5g of 80nm diameter The germanium-doped nano-silicon was dispersed in the above solution, stirred continuously at 25°C for 18h, the obtained solution was centrifuged and washed 3 times with deionized water, kept at 80°C in a vacuum drying oven for 12h, placed in a box ...

Embodiment 2

[0215] (1) Mix elemental silicon powder and germanium powder in a VC mixer at a mass ratio of 90:10 at 150rpm for 8min, place in a vacuum high-temperature furnace, evacuate to below 50Pa, heat up to 1300°C, keep the temperature for 4 hours, and wait until the powder is completely evaporated After condensing to 250°C, the condensed germanium-doped nano-silicon is collected for use.

[0216] (2) Disperse 3.5g of dopamine hydrochloride in 2L of deionized water, continue stirring, add 0.04g of sodium hydroxide, then dropwise add tris hydrochloride solution to adjust the pH value to 8.5, then 7g of diameter is 80nm The silicon powder was dispersed in the above solution, stirred continuously at 25°C for 18h, the obtained solution was centrifuged and washed with deionized water for 3 times, kept at 80°C in a vacuum drying oven for 12h, placed in a box furnace, and kept at 1300°C under an argon atmosphere. 1h, get SiC / Si 3 N 4 Coated nanosilicon.

[0217] (3) Disperse the sample ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com