Composite oxidized particle filter material and preparation method thereof

A particle filter material and composite oxidation technology, applied in chemical instruments and methods, separation methods, filtration separation, etc., can solve problems such as clogging, lack of oxidation reaction adjuvants, incomplete chemical composition of filter materials, etc., to prevent clogging, increase The effect of moisturizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A composite oxide particle filter material, the monomer is a granular sandwich sphere structure, including an inner core skeleton and an outer wrapping layer, the inner core skeleton is a glassy porous particle made by sintering, and its shape nonuniformity coefficient d60 / d10 is 1.0~ 1.5, the equivalent particle size is 3~5mm, and the specific surface area is 5.0~8m 2 / g, the apparent density is 300~400kg / m 3 . The inner core skeleton includes the following components in parts by weight: 80-85% of waste glass, 6-8% of silicon carbide as a foaming agent, and 10-12% of sodium silicate as a sintered coupling agent.

[0049] Among them, the glass is waste glass, which is processed by a crusher and a grinder to become a powder of more than 200 meshes. After adding a foaming agent and a sintering coupling agent in proportion, the particles of the desired size are formed by embryo forming and granulation, respectively. Then, it is sintered at a temperature of 800-900° C. to...

Embodiment 2

[0059] A composite oxide particle filter material, the monomer is a granular sandwich ball structure, including an inner core skeleton and an outer wrapping layer, the inner core skeleton is a ceramic porous particle made by sintering, the equivalent particle size is 2-4mm, and the specific surface area is 2-4mm. 5.0~10m 2 / g, the apparent density is 500~800kg / m 3 . The inner core framework includes the following components by weight: 80-85% mullite (containing 20-22.5% SiO 2 , 60~67.5% Al 2 O 3 , 0.1-0.8% CaO, 0.2-0.9% Fe 2 O 3 , 0.02~0.06% MnO, 0.02~0.06% P 2 O 5 , 0.05~0.075% K 2 O and 0.5 to 0.75% Na 2 O), 6-8% calcium carbonate as foaming agent, 10-12% attapulgite as sintering coupling agent.

[0060] Among them, the mullite is processed by a crusher and a grinder to become a powder of more than 200 meshes. After adding a foaming agent and a binder in proportion, the mullite is embryonic and granulated to make particles of the desired size, and then at 800 Sint...

Embodiment 3

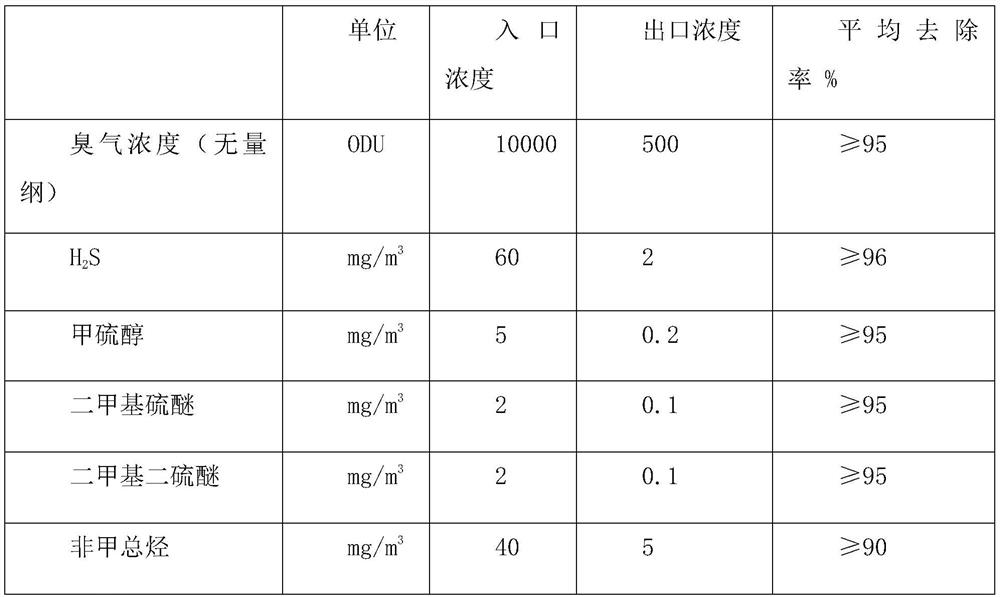

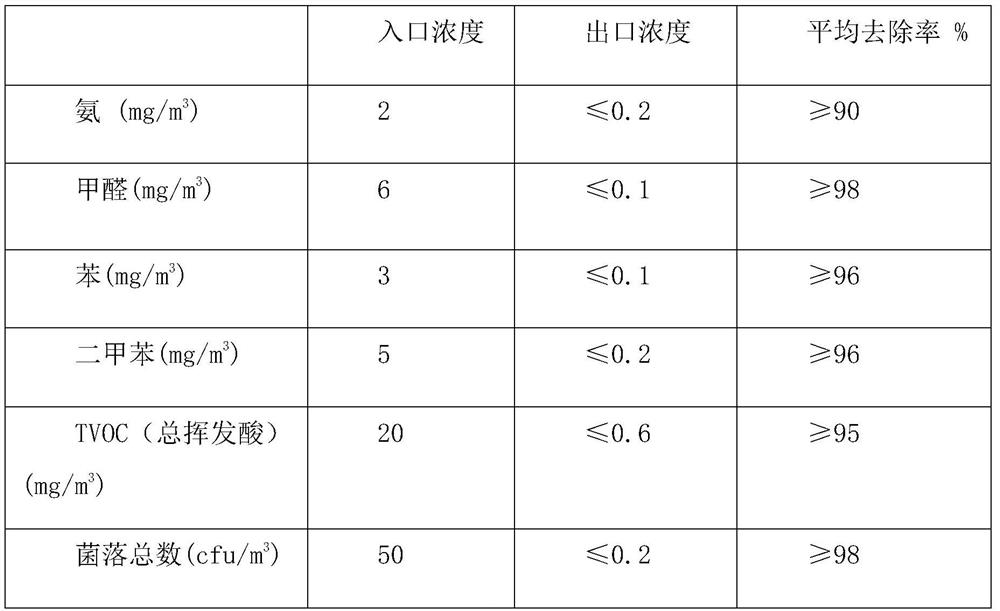

[0071] The composite oxidized particle filter material prepared in Example 1 or 2 was loaded into the filter bed of a dry chemical adsorption filter device to obtain a dry chemical adsorption filter device. In the dry chemical adsorption filter device, the bulk density of the composite oxide particle filter material is 950kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com