Waste plastic derived nano-porous carbon material as well as preparation method and application thereof

A technology of nanoporous carbon and waste plastics, applied in the direction of nanocarbon, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of increased preparation costs, environmental hazards, and complicated processes, so as to avoid equipment loss and Effects of waste acid treatment, avoiding corrosion, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

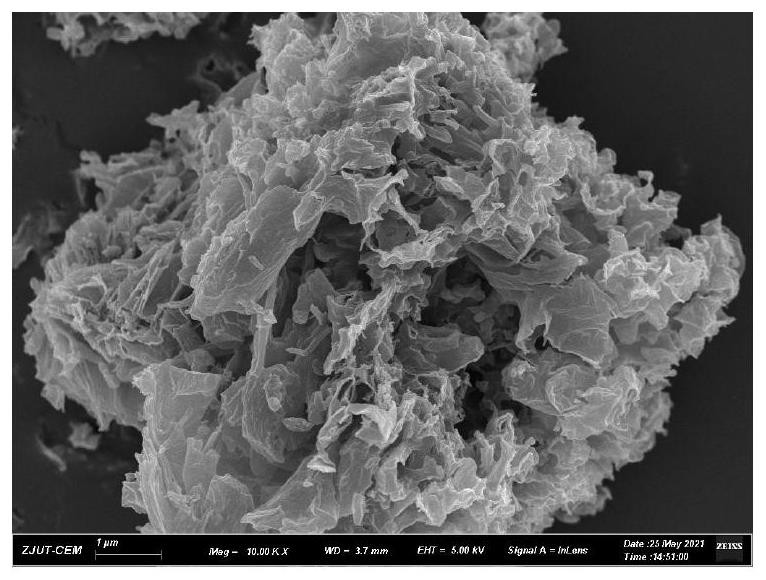

[0031] Embodiment 1 The preparation method of waste plastic-derived nanoporous carbon material specifically includes the following steps:

[0032] (1) get a polyvinyl chloride waste plastic handbag and put it into a crusher for crushing to obtain polyvinyl chloride waste plastic powder;

[0033] (2) Weigh 10g of melamine and 10g of polyvinyl chloride waste plastic powder respectively in a ball mill jar, add 20mL of N,N-dimethylformamide and 200g of stainless steel balls, and ball-mill at 500 rpm for 4h to obtain a mixed product ;

[0034] (3) Washing the mixed product with deionized water and drying at 100 °C for 10 h to obtain a porous carbon precursor;

[0035] (4) Put the porous carbon precursor into a tube furnace, and under a nitrogen atmosphere (the flow rate of nitrogen is 50 mL / min, and the inert gas conditions of Example 3-8 are the same), the temperature is raised to 600 ° C at a heating rate of 5 ° C / min After calcining for 2 hours, naturally cooled to room temper...

Embodiment 2

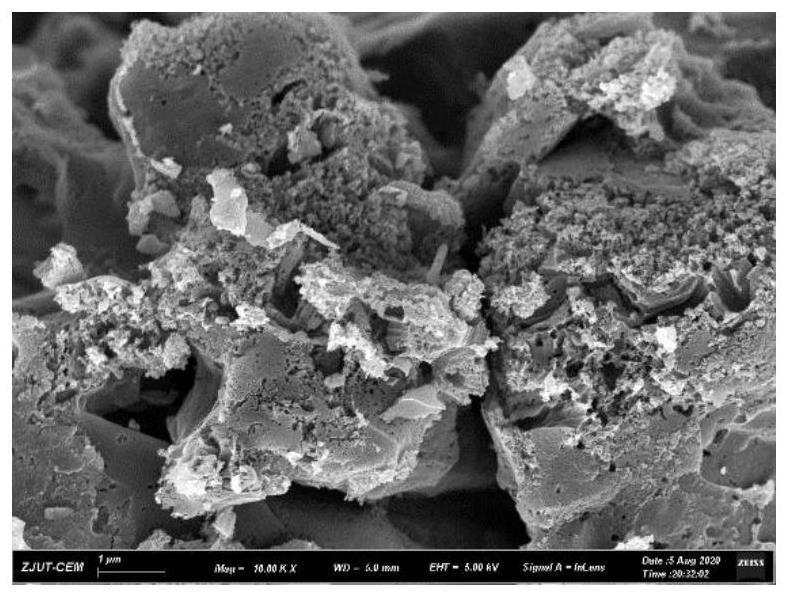

[0036] Embodiment 2 The preparation method of waste plastic-derived nanoporous carbon material specifically comprises the following steps:

[0037] (1) get a polyvinyl chloride waste plastic handbag and put it into a crusher for crushing to obtain polyvinyl chloride waste plastic powder;

[0038] (2) respectively weighing 5g melamine and 10g polyvinyl chloride waste plastic powder in a ball mill jar, adding 20mL tetrahydrofuran, adding 225g stainless steel balls, then ball milling at 600 rpm for 2h to obtain a mixed product;

[0039] (3) Washing the mixed product with deionized water and drying at 80 °C for 12 h to obtain a porous carbon precursor;

[0040] (4) Put the porous carbon precursor into a tube furnace, under a helium gas atmosphere (the flow rate of helium gas is 100mL / min), heat up to 900°C for 1 h at a heating rate of 10°C / min, and cool to room temperature naturally, That is, a nanoporous carbon material derived from polyvinyl chloride waste plastic is obtained, ...

Embodiment 3

[0041] Embodiment 3 The preparation method of waste plastic-derived nanoporous carbon material specifically includes the following steps:

[0042] (1) get a polyvinyl chloride waste plastic handbag and put it into a crusher for crushing to obtain polyvinyl chloride waste plastic powder;

[0043] (2) Weigh 20g of melamine and 10g of polyvinyl chloride waste plastic powder respectively in a ball mill jar, add 20mL of N,N-dimethylformamide, add 300g of stainless steel balls, and then ball-mill at 500 rpm for 4h to obtain a mixed solution product;

[0044] (3) Washing the mixed product with deionized water and drying at 100 °C for 10 h to obtain a porous carbon precursor;

[0045] (4) Put the porous carbon precursor into a tube furnace, heat it up to 600 °C for 2 h at a heating rate of 8 °C / min under a nitrogen atmosphere, and cool it to room temperature naturally to obtain nanoporous carbon derived from polyvinyl chloride waste plastics. Material, carbon yield: 11.5%, nitrogen ...

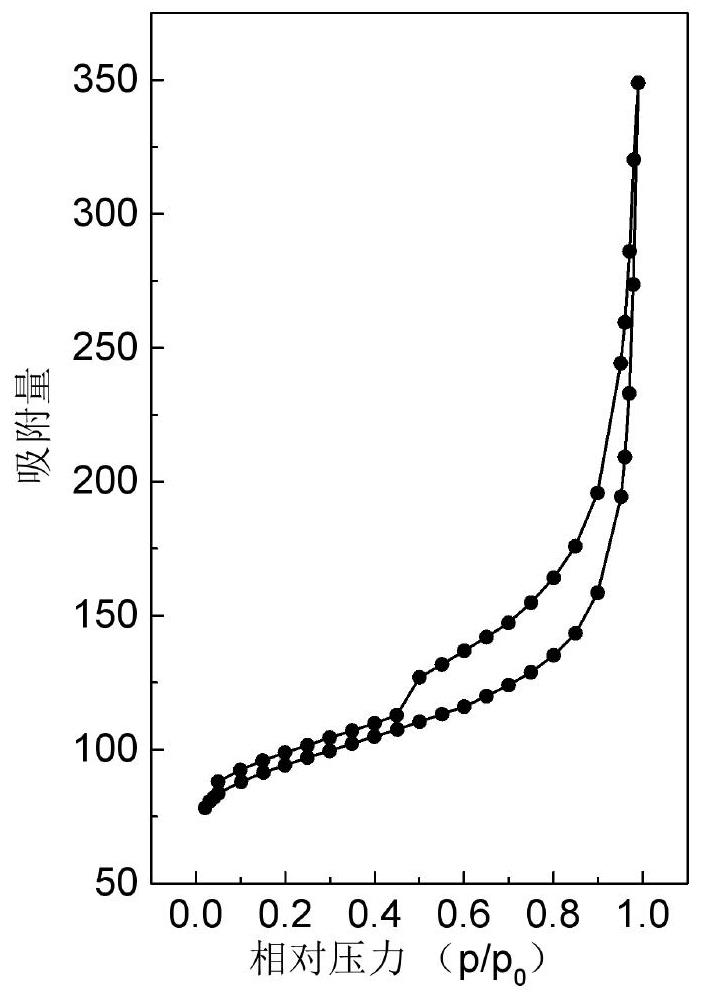

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com