Temperature field control method in laser additive manufacturing process

A control method and manufacturing process technology, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve problems affecting the performance of components, different microstructures, etc., and achieve easy promotion, reduction of residual stress, and realization of process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

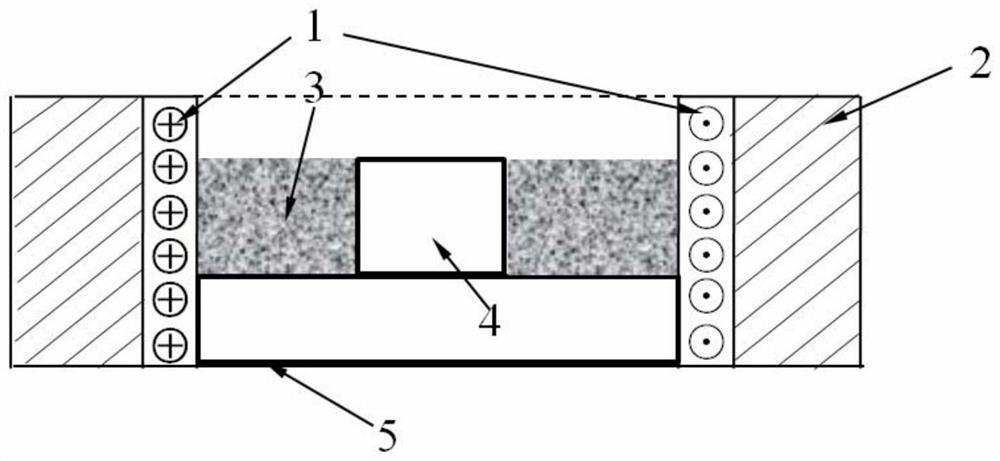

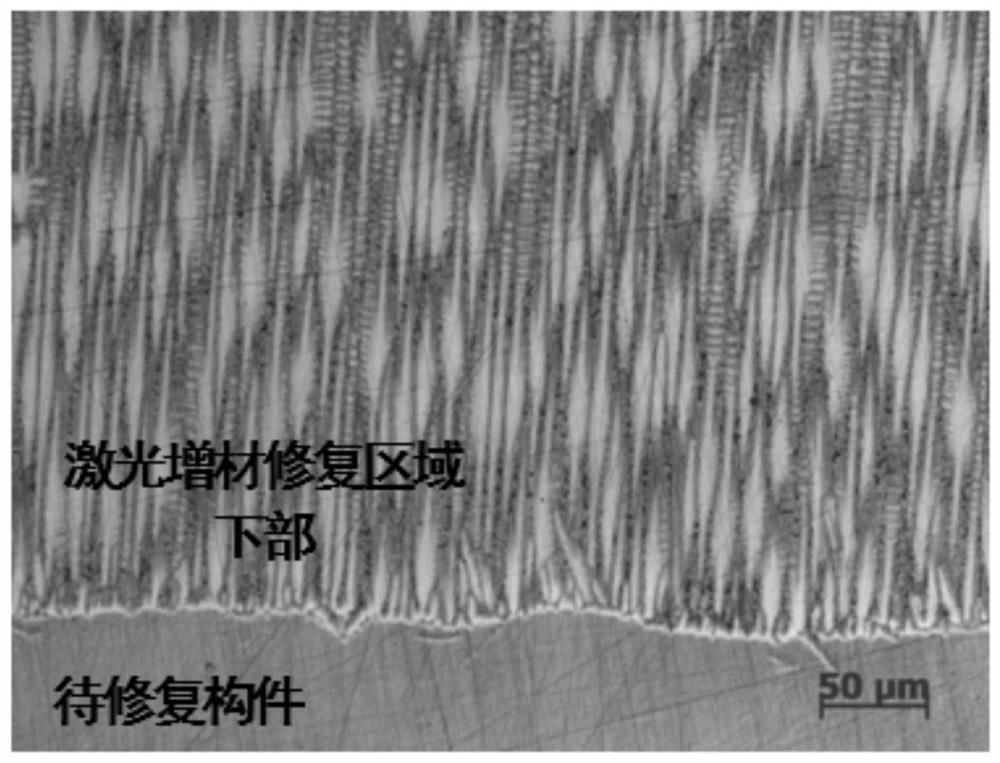

[0041] This embodiment adopts the control method of the temperature field provided by the present invention to carry out the laser powder feeding and additive repair and remanufacturing of the difficult-to-weld DD5 nickel-based superalloy component, and the technological process is as follows:

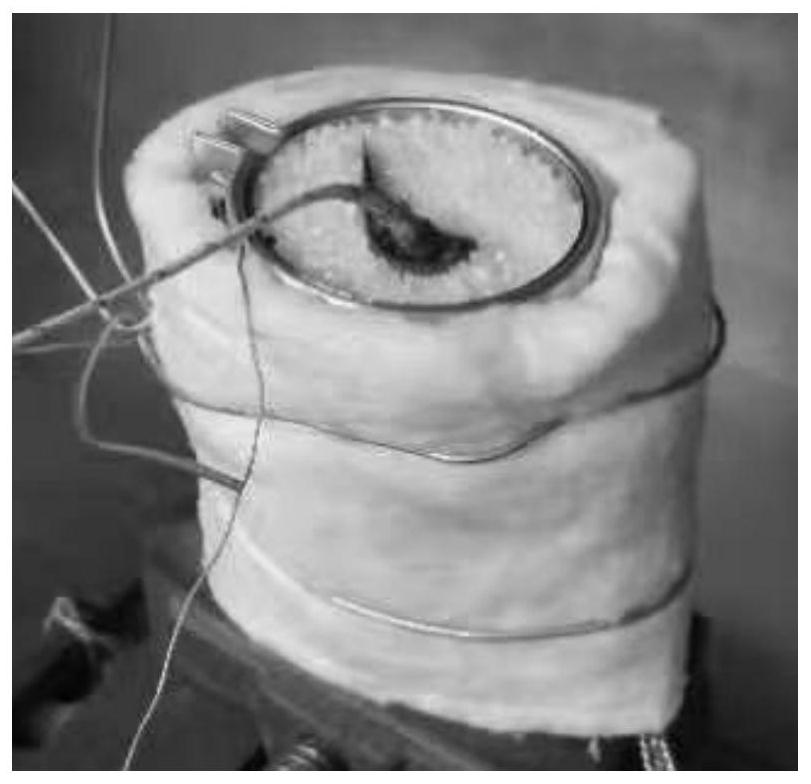

[0042] (1) Preparation of external heating device: The nickel-chromium resistance strip is prepared into a cylindrical heating device with a diameter of 100mm, and a layer of insulation cotton is laid around the periphery of the resistance strip, and a base is placed at the bottom of the device. This heating device is connected with a low voltage regulated power supply, and the heating rate can be adjusted by changing the voltage.

[0043] (2) Filling of thermal insulation sand: Fix the component to be repaired on the inner base of the above-mentioned cylindrical heating device, spread thermal insulation sand around the blade, and bury most of the area of the component to be repaired ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com