Method for preparing manganous-manganic oxide from lean manganese ore

A technology of trimanganese tetroxide and poor manganese ore, which is applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of difficult electrolytic manganese slag treatment, environmental pollution, and difficult production of manganese ore, so as to realize repeated utilization, simple process, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] like figure 1 Shown, a kind of method utilizing lean manganese ore to prepare manganese tetroxide, comprising the following steps:

[0050] (1) Grind the lean manganese ore to a fineness of -0.074mm accounting for more than 95%, add concentrated sulfuric acid with a mass concentration of 92.5%, then add hydrogen peroxide as an oxidant, oxidize ferrous iron into ferric iron, add sodium carbonate as a Neutralizer, after solid-liquid separation, manganese sulfate solution and leached manganese slag are obtained. The leached manganese slag does not contain ammonia nitrogen, which is more advantageous for making building materials;

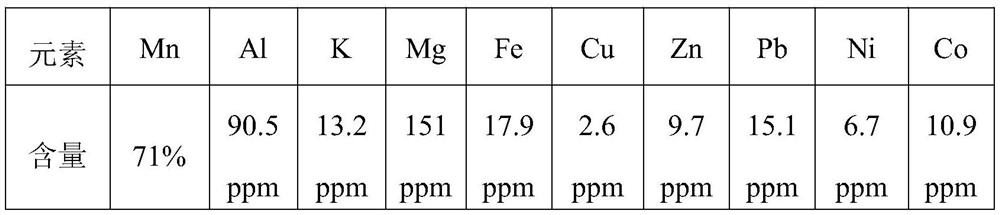

[0051] (2) adding fumet sodium (SDD) to the manganese sulfate solution, removing heavy metals, solid-liquid separation, obtaining purified liquid and sulfide slag, realizing the classification of manganese slag, and the sulfide slag is used to extract nickel-cobalt-manganese-zinc valuable elements;

[0052] (3) adding electrolytic additives (se...

Embodiment 2

[0076] A method for utilizing lean manganese ore to prepare manganese tetroxide, comprising the following steps:

[0077] (1) Grind the lean manganese ore to a fineness of -0.074mm accounting for more than 95%, add concentrated sulfuric acid with a mass concentration of 92.5%, and then add manganese dioxide ore powder as an oxidant to oxidize ferrous iron into ferric iron, add Sodium bicarbonate is used as a neutralizing agent. After solid-liquid separation, manganese sulfate solution and leached manganese slag are obtained. The leached manganese slag does not contain ammonia nitrogen, which is more advantageous for making building materials;

[0078] (2) adding fumet sodium (SDD) and sodium sulfide to the manganese sulfate solution, removing heavy metals, separating solid-liquid, obtaining purified liquid and sulfide slag, realizing manganese slag classification, and the sulfide slag is used to extract nickel, cobalt, manganese, and zinc valuable elements;

[0079] (3) adding...

Embodiment 3

[0082] A method for utilizing lean manganese ore to prepare manganese tetroxide, comprising the following steps:

[0083] (1) Grind the lean manganese ore to a fineness of -0.074mm accounting for more than 95%, add concentrated sulfuric acid with a mass concentration of 92.5%, and then add hydrogen peroxide as an oxidant to oxidize ferrous iron into ferric iron, add sodium carbonate, The mixture of sodium bicarbonate is used as a neutralizing agent. After solid-liquid separation, manganese sulfate solution and leached manganese slag are obtained. The leached manganese slag does not contain ammonia nitrogen, which is more advantageous for making building materials;

[0084] (2) adding sodium fumet (SDD) and barium sulfide to the manganese sulfate solution, removing heavy metals, separating solid-liquid, obtaining purified liquid and sulfide slag, and realizing the classification of manganese slag, and the sulfide slag is used to extract nickel-cobalt-manganese-zinc valuable elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com