Microemulsion composition of oleanolic acid as well as preparation method and application of microemulsion composition

The technology of oleanolic acid and composition is applied in the fields of oleanolic acid micro-emulsion composition and preparation of cosmetics and external skin preparations, which can solve the problems of easy degradation and instability, achieve good light transmittance, slow down volatilization and the like. , good sensory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

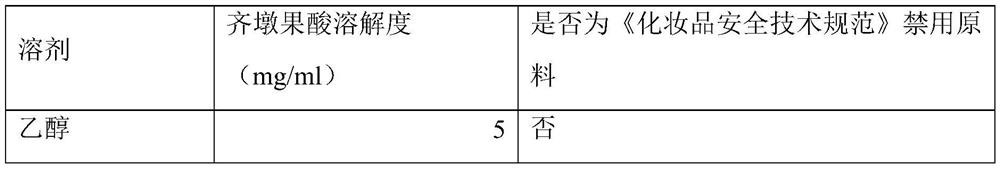

[0118] A kind of oleanolic acid microemulsion, including each raw material component of following weight percent, as shown in table 1:

[0119] Table 1

[0120]

[0121]

[0122] Preparation:

[0123] S1-1. take by weighing dipropylene glycol, ethanol, glycerol polyether-26, rosemary essential oil, cedarwood essential oil and octyl glucoside, polyoxyethylene 35 castor oil, mix and stir in container A, then add the amount of Oleanolic acid is stirred until completely dissolved to obtain a lipophilic phase;

[0124] S1-2. Weigh hydroxypropyl-β-cyclodextrin, add in the water in container B to dissolve, then add carboxymethyl chitosan and stir to obtain water phase after fully swelling;

[0125] S1-3. The lipophilic phase is slowly added to the water phase while stirring to self-emulsify to obtain clear and transparent microemulsion colostrum;

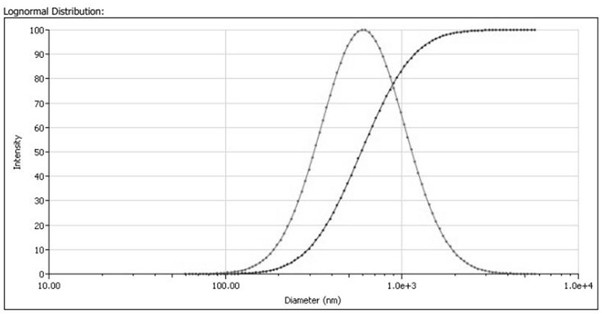

[0126] S1-4. Lecithin was added to container B, followed by stirring with a high-speed homogenizer at 18,000 rpm for 10 minutes ...

Embodiment 2

[0127] Embodiment 2: An oleanolic acid nanostructure lipid carrier, comprising the finished product of the microemulsion prepared by each raw material component in Example 1 and each raw material component in the following weight percentages: 1.2% glycerol monostearate, 0.8% beeswax %, Poloxamer 1885%.

[0128] Preparation:

[0129] S2-1. Add the microemulsion prepared in Example 1 into container D, heat to 65-70°C and keep this temperature;

[0130] S2-2. Weigh glyceryl monostearate, beeswax and poloxamer 188 and add to container C, heat to 65-70°C until transparent melt is obtained;

[0131] S2-3. Add the transparent melt in the container C to the microemulsion in the container D, stir and mix to obtain a clear and transparent hot microemulsion;

[0132] S2-4. The hot microemulsion was stirred with a high-speed homogenizer at 18,000 rpm for 5 minutes, and treated with a sonicator with a power of 400 W for 10-20 minutes, followed by cooling in an ice-water bath to obtain a ...

Embodiment 3

[0134] A kind of oleanolic acid microemulsion, including each raw material component of following weight percent, as shown in table 2:

[0135] Table 2

[0136]

[0137]

[0138] Preparation:

[0139] S1-1. Weigh isosorbide dimethyl ether, isopentane glycol, tea tree essential oil, peppermint essential oil, oriental orientalis essential oil and Tween 20, fatty alcohol polyoxyethylene ether (AEO-9), decyl glucoside in a container Mix and stir evenly in A, then add the formula amount of oleanolic acid and stir until completely dissolved to obtain a lipophilic phase;

[0140] S1-2. Add an appropriate amount of water in container B, then add hydroxypropyl chitosan and stir until fully swollen to obtain a water phase;

[0141] S1-3. The lipophilic phase is slowly added to the water phase while stirring to self-emulsify to obtain clear and transparent microemulsion colostrum;

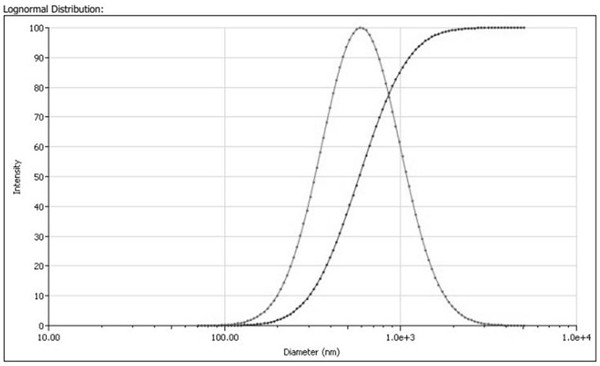

[0142]S1-4. Then use a high-speed homogenizer to stir at 16,000 rpm for 12 minutes to obtain a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com