Micromolecule organic light detector and preparation method thereof

A photodetector and small molecule technology, applied in organic chemistry, semiconductor/solid-state device manufacturing, electrical solid-state devices, etc., can solve the problems of vacuum evaporation processing, modification limitation, process incompatibility, etc., to prevent high temperature Risk of decomposition or denaturation, remarkable effect of photoelectric response, effect of reducing energy consumption and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

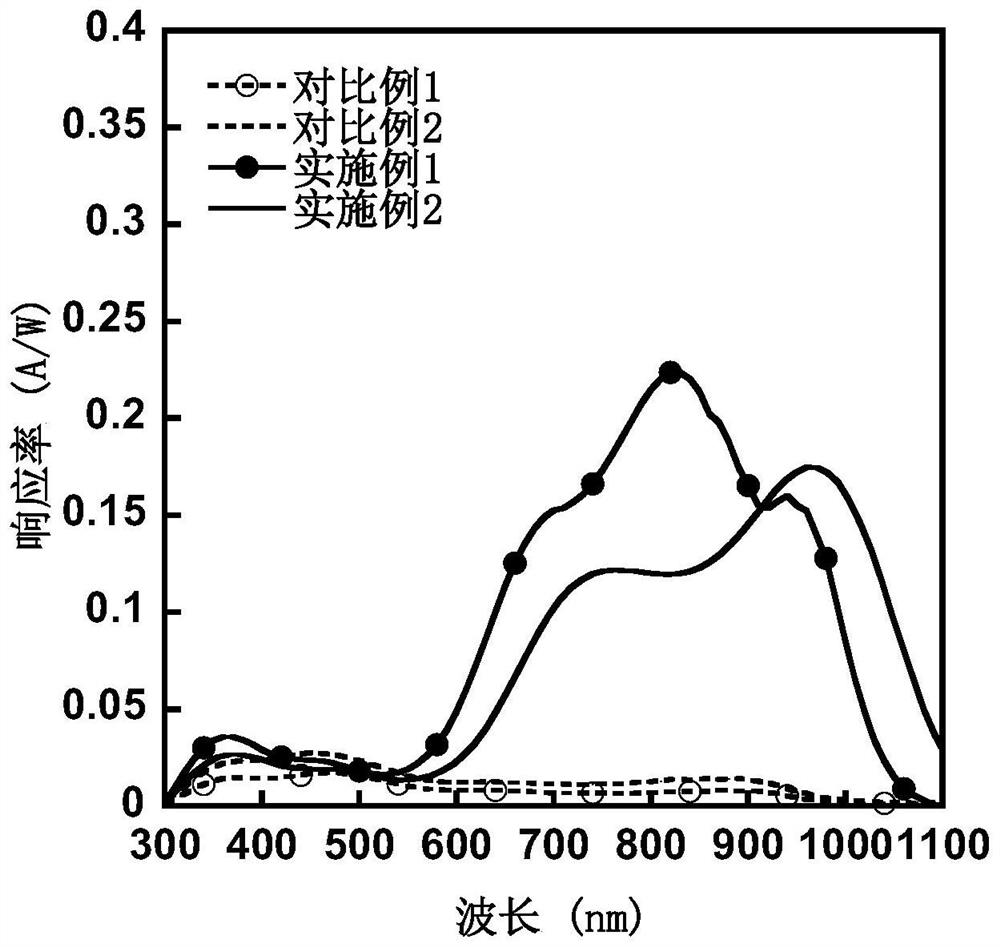

Embodiment 1

[0075] A small molecule photodetector, the structure from bottom to top is: ITO(100nm) / MoO 3 (8nm) / cuprous iodide (2nm) / 2,3-naphthaldehyde anthocyanin: lead bis(2,2,6,6,-tetramethyl-3,5-heptanedionate) (1.2: Composite film of 1, n / n, 40 nm) / C60 (40 nm) / LiF (1 nm) / Al (100 nm).

[0076] The preparation method of the above-mentioned small molecule photodetector is as follows:

[0077] S1. Place the ITO glass substrate on the developing rack, use an ultrasonic to ultrasonically clean it, and use the washing liquid in the order of acetone, isopropanol, detergent, deionized water and isopropanol, and then dry it in a vacuum oven ;

[0078] S2. The ITO is placed in an oxygen plasma generator, and an oxygen plasma (O 2 Plasma) for 2min bombardment to completely remove possible residual organics on the surface of the ITO glass substrate;

[0079] S3. Put the above-treated ITO substrate into the vacuum evaporation equipment, and under the condition that the vacuum degree is less th...

Embodiment 2

[0085] A small molecule photodetector, the structure from bottom to top is: ITO(120nm) / MoO 3 (10 nm) / cuprous iodide (3 nm) / compound M1: lead acetate (~0.6:1 composite film, n / n, 30 nm) / C60 (30 nm) / lithium fluoride (1 nm) / Al (100 nm).

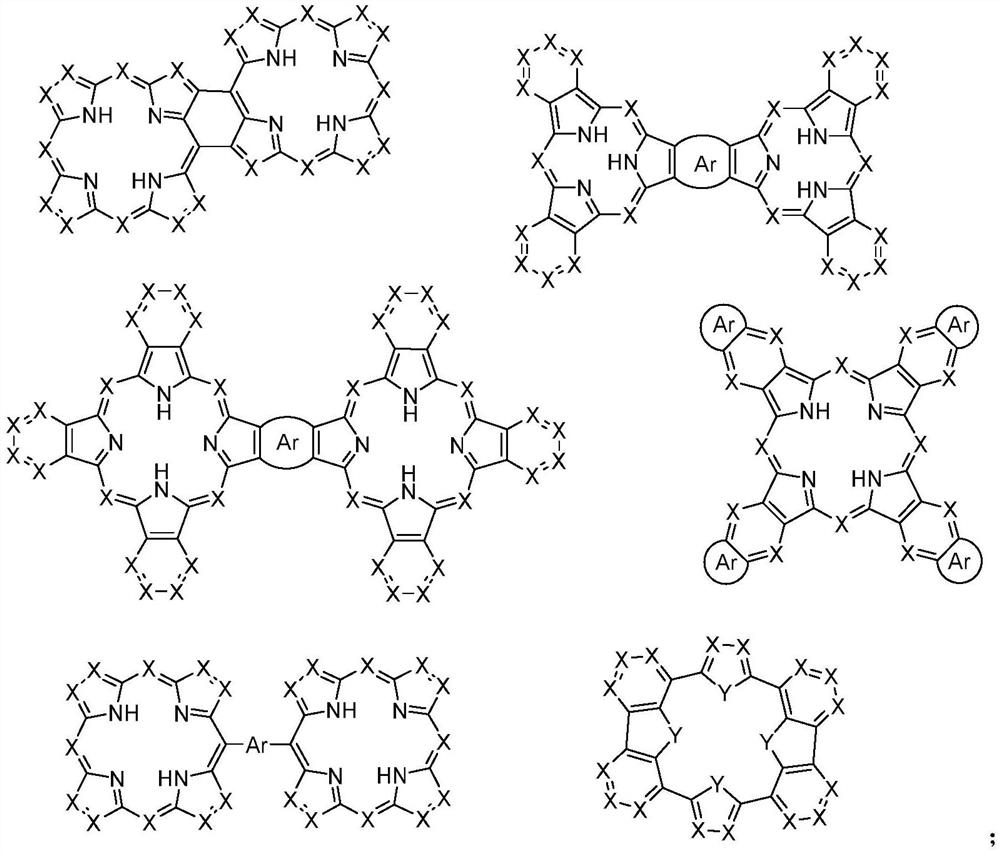

[0086] The molecular formula and preparation method of above-mentioned compound M1 are as follows:

[0087]

[0088] Under nitrogen protection, 1.15 g of magnesium turnings (47.1 mmol) were added to 400 ml of n-butanol, and the temperature was raised to 125° C. for reflux reaction for 3 h until the magnesium turnings were completely dissolved. After cooling to room temperature, 1.00 g of compound 1 (4.7 mmol) and 1,2-dicyanobenzene for 4.83 h (37.7 mmol) were added to the reaction solution, stirred for 5 min, and then heated to 125 °C and refluxed for 48 h. After the reaction was completed, it was returned to room temperature, and 1.0 L of anhydrous methanol was added to the reaction solution, followed by stirring for 1 h. The reaction syst...

Embodiment 3

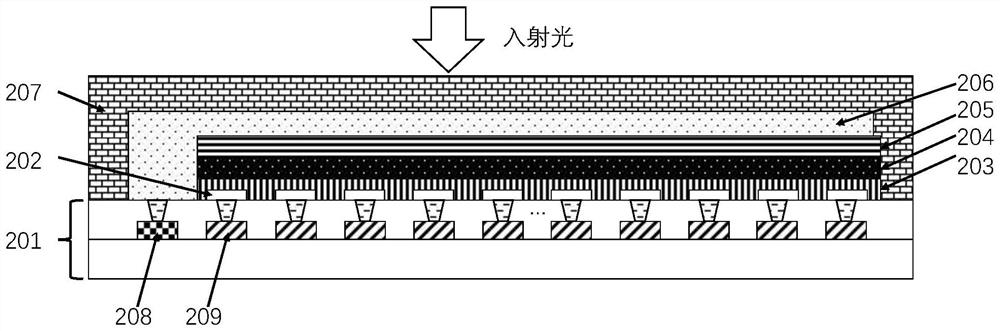

[0098]A small molecule photodetector array, the array is, from bottom to top, a pixel readout circuit array chip 201 made on a single crystal silicon substrate and composed of a silicon-based complementary metal-oxide-semiconductor transistor (MOSFET). , The readout circuit of each pixel is linked to the anode array 202 which defines the size of the pixel; above the electrode array are the hole transport layer 203 , the photosensitive layer 204 , the electron transport layer 205 , the common cathode layer 206 and the encapsulation layer 207 . Among them, 201 contains the connection contact 208 of the upper electrode and the single pixel readout circuit 209 connected to 202. The structures from 203 to 207 are continuous in the entire array area, and do not need patterning processing between pixels.

[0099] The patterned anode array 202 is a gold electrode with a thickness of 100 nm, the hole transport layer 203 is a stacked structure of a molybdenum oxide film (8 nm) and a cup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com