Preparation method of high-dispersion hydrated silicon dioxide for silicone rubber

A hydrated silica, high dispersion technology, applied in silica, silica, chemical instruments and methods, etc., can solve the problems of slow powder consumption, high energy consumption, large dust, etc. Reduce gel generation and reduce particle agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention relates to a kind of preparation method of high-dispersion hydrated silica for silicone rubber, comprising the following steps:

[0033] Step 1: Preparation of reaction materials, including:

[0034] The silane coupling agent is hydrolyzed by adding the hydrolyzed solution previously compounded by water and polyol to obtain silane hydrolyzed solution C; the silane coupling agent is selected from one or two compounds of HMDS or KH550. The polyol is n-butanol or glycerol; the mass ratio of the silane coupling agent, water and polyol is 1:4-6:2;

[0035] Take low-iron solid water glass (iron content ≤ 120ppm) and purified process water (conductivity ≤ 100μs / cm) into the autoclave successively in a certain proportion, pass 0.7MPa steam to dissolve, and maintain the pressure for 2-2.5h. Then put it into the storage tank for more than 24 hours, and filter it with a plate and frame filter press; after the sodium silicate and purified process water obtain...

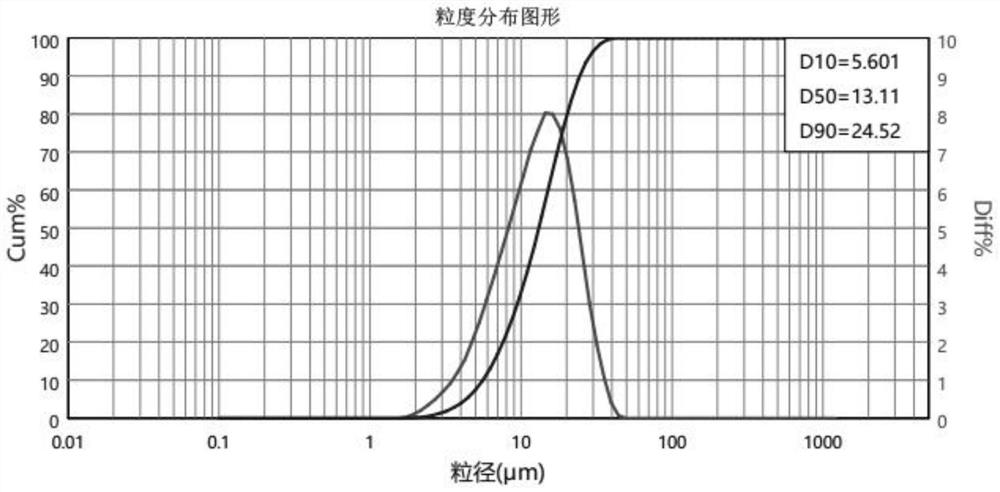

Embodiment 1

[0043] A preparation method of highly dispersed hydrated silica for silicone rubber, comprising the following steps:

[0044] Step 1: Preparation of reaction materials, including:

[0045] 10.5kg of HMDS was added to 50kg of 10% glycerol solution, and hydrolyzed at room temperature for 20min under stirring to obtain silane hydrolyzed solution C;

[0046] Take 7t low iron solid water glass (iron content≤120ppm) and 14m 3 Purified process water (conductivity≤100μs / cm) was added to the autoclave successively, 0.7MPa steam was introduced for dissolution, and the pressure was maintained for 2.5h. Then put it into the storage tank for more than 24 hours, and filter it with a plate and frame filter press; after the sodium silicate and purified process water obtained after filtration are evenly mixed according to a mass ratio of 1:0.4, they are filtered by a plate and frame filter press and a bag filter. After filtration, it is pumped into the storage tank, and silane hydrolyzed sol...

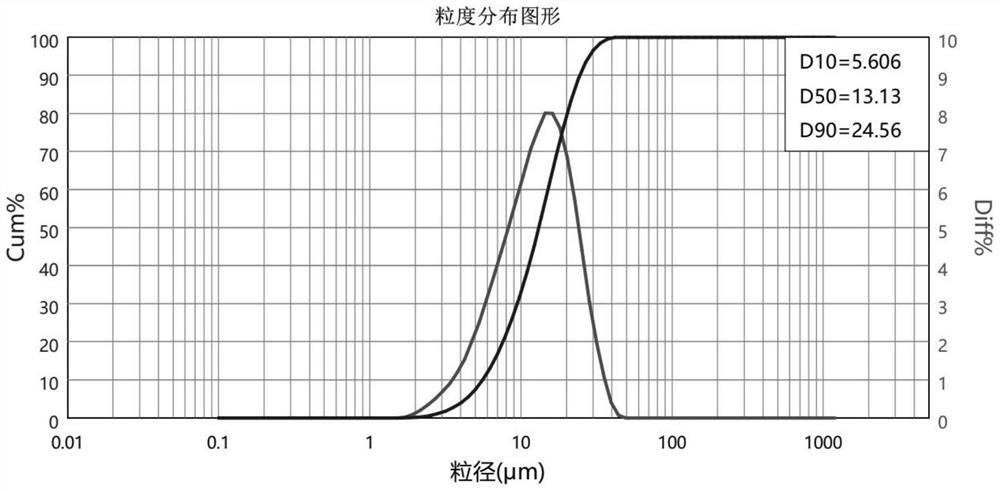

Embodiment 2

[0054] A preparation method of highly dispersed hydrated silica for silicone rubber, comprising the following steps:

[0055] Step 1: Preparation of reaction materials, including:

[0056] 10.5kg of HMDS was added to 50kg of 10% glycerol solution, and hydrolyzed at room temperature for 20min under stirring to obtain silane hydrolyzed solution C;

[0057] Take 7t low iron solid water glass (iron content≤120ppm) and 14m 3 Purified process water (conductivity ≤ 50μs / cm) was added to the autoclave successively, 0.7MPa steam was introduced for dissolution, and the pressure was maintained for 2.5h. Then put it into the storage tank for more than 24 hours, and filter it with a plate and frame filter press; after the sodium silicate and purified process water obtained after filtration are evenly mixed according to a mass ratio of 1:0.4, they are filtered by a plate and frame filter press and a bag filter. After filtration, it is pumped into the storage tank, and silane hydrolyzed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com