Composite nano germicide and its prepn

A nanocomposite and antibacterial agent technology, applied in the field of nanomaterials, can solve the problems of less antibacterial active ingredients, no antibacterial properties of carrier materials, and large dosage of antibacterial agents, and achieve enhanced affinity, large specific surface area, and improved bactericidal ability and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

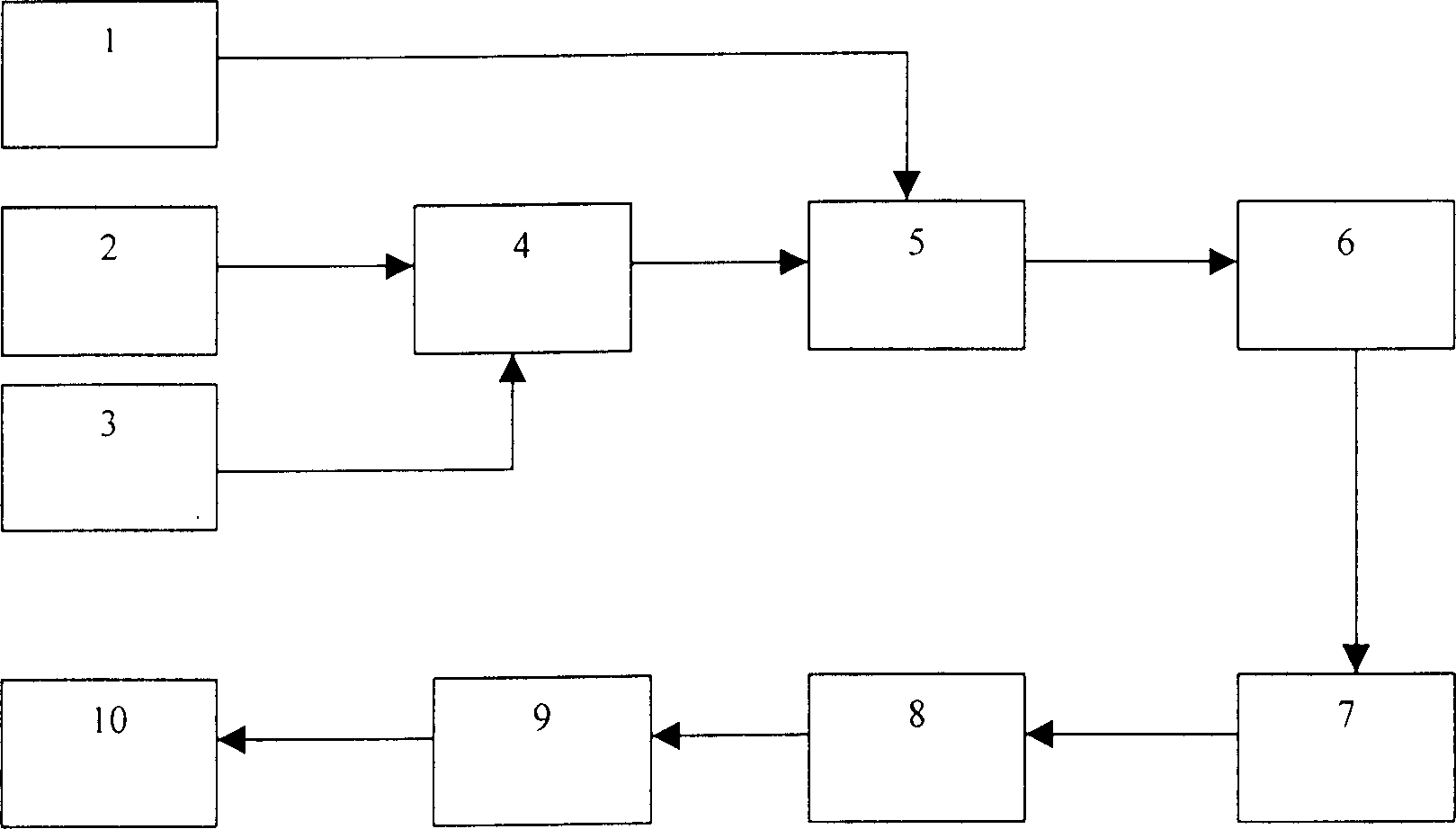

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 Nanocomposite antibacterial agent and preparation method thereof:

[0016] 1, the nanocomposite antibacterial agent of this example, its each component ratio is: zinc oxide: copper carbonate: silver chloride: cerium sulfate: calcium phosphate: titanium sulfate: cationic imidazoline=85%: 0.1%: 1%: 1 %: 9%: 1.9%: 2%, (percentage by weight), the sum of the proportions of each component is 100%.

[0017] 2. The preparation method of the nano-composite antibacterial agent of this example: prepare zinc-ammonia complex solution with 85% zinc oxide according to the requirements of patent ZL98 1 16820.5, and add 0.1% copper carbonate, 1% silver chloride, and 1% cerium sulfate respectively in order , 9% calcium phosphate, 1.9% titanium sulfate, heat the solution to 40 ° C, chemical co-precipitation at PH = 8.5, add 2% cationic imidazoline solution, filter, wash, dry, and calcinate to obtain the finished product, which is used in plastic products Added in, the antiba...

Embodiment 2

[0018] Embodiment two nanocomposite antibacterial agent and preparation method thereof:

[0019] 1, the nanocomposite antibacterial agent of this example, its each component ratio is: zinc oxide: copper acetate: silver nitrate: thorium sulfate: lanthanum nitrate: glutaraldehyde: nonionic surfactant AEO9=55%: 15%: 12 %: 10%: 2%: 3%: 3%, (percentage by weight), the sum of the proportions of each component is 100%.

[0020] 2. The preparation method of the nanocomposite antibacterial agent of this example: 55% zinc oxide is prepared according to the requirements of the patent ZL981 16820.5 to prepare a zinc-ammonia complex solution, and 15% copper acetate, 12% silver nitrate, 10% thorium sulfate, 2% Lanthanum nitrate, 3% non-ionic surfactant AEO9, heating the solution to 98°C, chemical co-precipitation at PH=4, adding 3% glutaraldehyde, filtering, washing, drying, and calcining to obtain the finished product, which is used in coating products Added in, the antibacterial effect i...

Embodiment 3

[0021] Embodiment three nanocomposite antibacterial agent and preparation method thereof:

[0022]1, the nanocomposite antibacterial agent of this example, its each component ratio is: zinc oxide: copper sulfate: silver nitrate: cerium sulfate: lanthanum chloride: cationic quaternary ammonium salt=55%: 15%: 15%: 10%: 2%: 3%, (percentage by weight), the sum of the proportions of each component is 100%.

[0023] 2. The preparation method of the nanocomposite antibacterial agent of this example: prepare a solution with 55% zinc oxide according to the requirements of patent ZL98 1 16820.5, and add 15% copper carbonate, 15% silver nitrate, 10% cerium sulfate, and 2% lanthanum chloride in sequence 1. Heat the solution to 75°C, chemical co-precipitation at PH=7, add 3% cationic quaternary ammonium salt, filter, wash, dry, and calcinate to obtain a finished product, and add it to textile products for trial, and the antibacterial effect is very good. The killing rate of Staphylococcus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com