Active-carbon-fiber type solid-phase adsorption method for gas-phase chromatogram

A technology of activated carbon fiber and gas chromatography, which is applied in the field of analytical chemistry, can solve the problems of short service life, complicated production, long equilibration time, etc., and achieve the effects of long service life, convenient manufacture and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

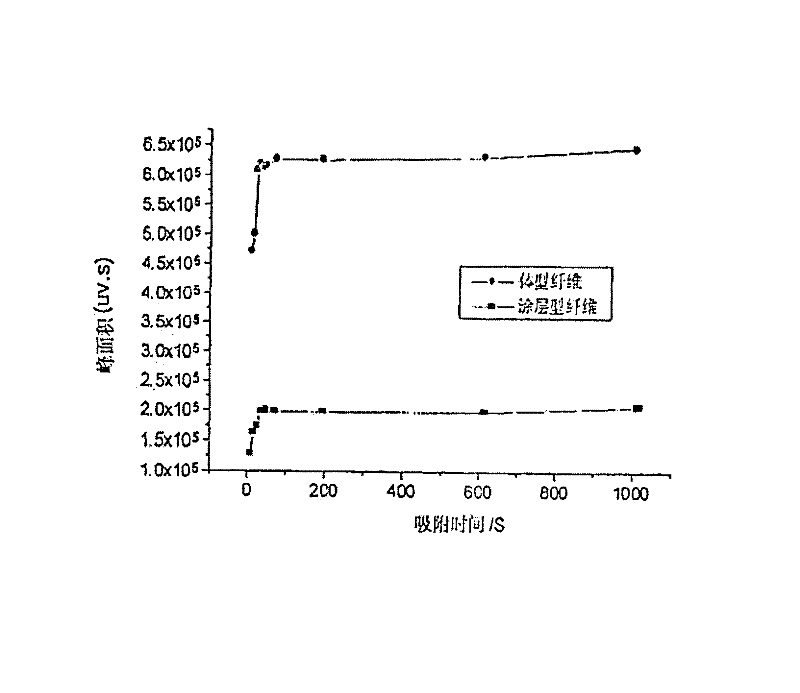

Image

Examples

Embodiment 1

[0023] Knead 15% of pitch, 70% of coke powder and 15% of kaolin at 200°C, press them at 350°C, and then put them in a tube furnace under N 2 Under the atmosphere, after carbonization at 1000°C, pass in water vapor for 20 minutes, and after cooling, activated carbon fibers will be obtained, which will be made into the required size and assembled into a solid-phase micro-adsorption device. Analyze the methanol in the mousse, the results are shown in Table 1 (use the commercially available polyacrylate SPEM to only measure the huge solvent peak in the mousse but no methanol peak, and the methanol peak in 1ml headspace is also covered by the impurity peak, In contrast, ACF shows very good selectivity, it reduces the impurity peaks by tens to hundreds of times, and concentrates the methanol peak.

[0024] Manufacturer's name

Shanghai Jahwa

beauty is treasure

green

methanol concentration

(v / v%)

0.01%

0.01%

0.01%

...

Embodiment 3

[0028] With 12% phenolic resin (polymerization degree as embodiment 2), 65% graphite powder and 23% montmorillonite powder as raw material, according to embodiment 1, make SPMA device, and measure the benzene industrial waste water with gas chromatography The perchlorethylene, and compared with GB (straight pumping headspace method). The results are shown in Table 2 and Table 3. This fiber has been used more than 300 times, and the adsorption performance has not changed significantly.

[0029] Concentration (mg / L)

SPME method

GB method

0.5

10295

5290

1

23377

13167

2

53333

23906

3

70561

37432

4

85123

44976

Sample to be tested

65931

33168

Sample to be tested +0.5

75197

38095

[0030] Water sample C 2 CL 4 contain

Quantity (mg / L)

Amount added

(mg / L)

Test results

(mg / L)

Recovery rate

(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com