Application type positive property thermal sensitive computer direct board and process for making same

A cloth-type positive, computer technology, which is applied in the field of coating heat-sensitive computer direct plate and its preparation, can solve the problems of increased cost, complicated procedures and the like, and achieves the effects of being beneficial to environmental protection, simple in preparation and low in cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

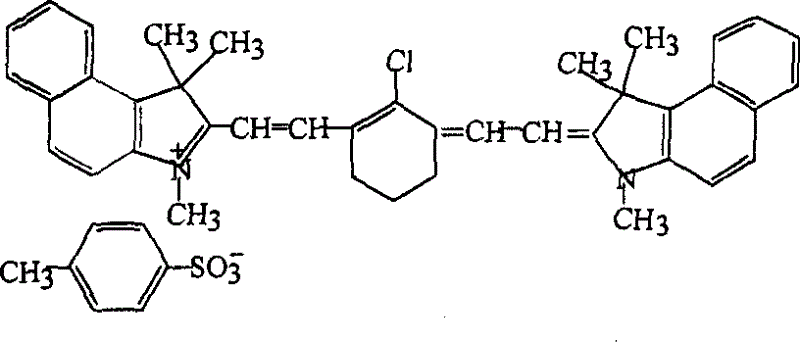

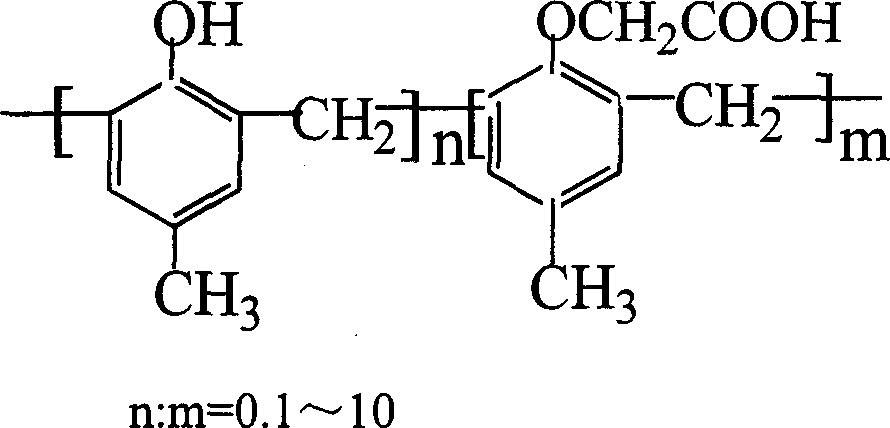

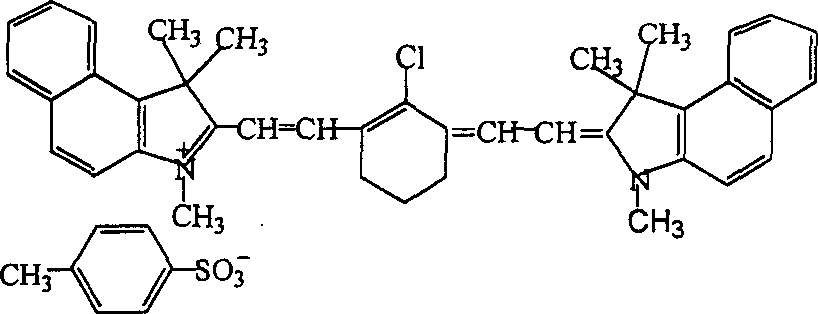

[0043] Get 1.2g of phenolic resin and p-cresol resin (weight ratio: 1:1), 0.55g of carboxymethylphenolic resin, 0.2g of infrared light absorber (830 laser dye), 0.02g of diphenyliodonium hexafluorophosphate , 0.34 g of hexamethoxymethyl melamine was added to a solvent system consisting of 5 ml of ethylene glycol monomethyl ether, 5 ml of ethanol, and 1 ml of dimethylformamide to form a coating solution. The coating liquid is coated on the electrolytic and anodized aluminum plate with a thickness of 0.3mm according to the coating method adopted by the usual positive-working PS plate, and is dried at 110°C for 2 minutes to obtain the present invention. computer-directed version of .

[0044] The computer direct plate that makes is scanned on thermal CTP plate-making machine (with 830nm semiconductor laser, Beijing Huatong Company), and the conditions are: 830nm semiconductor laser light intensity 220mW, image point diameter 10 μ m, exposure time 1 μ s (500 rpm / minute). The de...

Embodiment 2

[0046] Get 1.2g of phenolic resin and p-cresol resin (weight ratio: 1:1), 0.55g of carboxymethylphenolic resin, 0.2g of infrared light absorber (830 laser dye), 0.02g of diphenyliodonium hexafluorophosphate , 0.34g of hexamethoxymethyl melamine, 5ml of ethylene glycol monomethyl ether, 5ml of ethanol, and 1ml of dimethylformamide are mixed to form a coating solution, and the coating solution is coated on a thickness of 0.3 after electrolysis and anodic oxidation. mm aluminum plate, after drying at 110°C for 2 minutes, the computer-directed plate was obtained. Scanning is the same as in Example 1, except that the exposure time is 2 μs (250 rpm), and the development is the same as in Example 1 to obtain a clear image. The image is firmly combined on the plate base. After rubbing it back and forth for 100 times with an eraser, observe it with a microscope, and the image will not drop.

Embodiment 3

[0048] p-cresol resin (or phenolic resin) 1.2g, carboxymethyl p-cresol resin 0.55g, infrared light absorber (830 laser dye) 0.2g, diphenyliodonium hexafluorophosphate 0.02g, hexamethoxymethyl 0.34 g of melamine, 5 ml of propylene glycol monomethyl ether (or propylene glycol dimethyl ether), 5 ml of ethanol, 1 ml of dimethylformamide, and 3 ml of diethyl ether are added to form the coating solution. The scanning and developing conditions are the same as in Example 1, and a clear image is obtained. The image is firmly combined on the plate base, rubbed back and forth with an eraser 100 times, and observed with a microscope, the image will not drop.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com