Photoelectronic device and its producing method and electronic device with said photoelectronic device

An electro-optical device and a manufacturing method technology, which are applied to identification devices, cathode ray tubes/electron beam tubes, devices for coating liquid on surfaces, etc. bumpy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

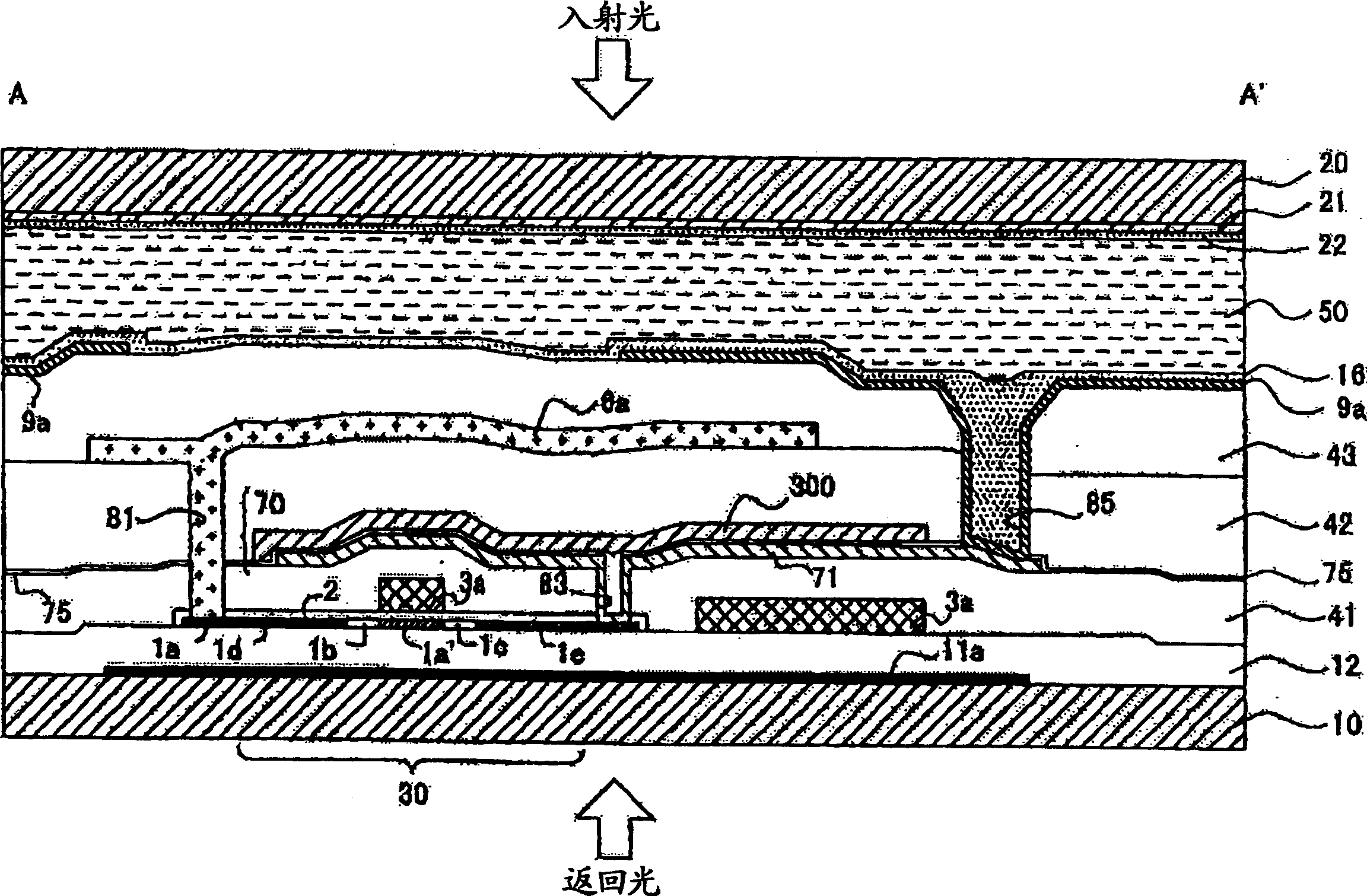

[0146] The electro-optical device was produced in the same manner as in the above-mentioned embodiment. At this time, as shown in FIG. 10, a pattern 61 is formed on the quartz substrate, and a BPSG film 62 with a film thickness of 800 nm is formed on the entire surface. The pattern 61 corresponds to the scanning line 3a of the embodiment, and the BPSG film 62 corresponds to the first interlayer insulating film 41 of the embodiment. Next, the substrate is heat-treated at a temperature of 890° C., and the BPSG film 61 is reflowed and planarized. After the processing, the inclination angle of the step portion of the BPSG film 62 generated by the pattern 61 is measured as the reflow angle θ.

[0147] The concentration of boron (B) in the BPSG film 62 was changed from 0.8% by weight to 5% by weight, and the above-mentioned measurement was performed for each case. In addition, the concentration of phosphorus (P) is all 6 wt%.

[0148] The measurement results obtained in this way are as ...

Embodiment 2

[0151] An electro-optical device was produced in the same manner as in Example 1. However, when the BPSG film 62 is formed on the quartz substrate on which the pattern 61 is formed, in this embodiment, the concentration of boron in the BPSG film 62 is fixed at 3% by weight, and the concentration of phosphorus (P) is fixed at 6% by weight. On this basis, the heating temperature (reflow temperature) was changed to 850°C, 900°C, and 950°C for flattening, and the reflow angle θ was measured for various situations.

[0152] The measurement results obtained in this way are as Picture 12 Shown. Picture 12 It represents the change of the reflow angle θ with respect to the reflow temperature of the BPSG film 62. When the reflow temperature is about 850°C, the reflow angle θ is about 86°, and the step is still steep. However, when the reflow temperature is about 900°C, the reflow angle θ is about 45°, and it can be seen that the step has become gentle. Furthermore, when the reflow tempera...

Embodiment 3

[0155] Below, Table 1 shows the precipitation status of phosphorus and boron. The amount of phosphorus and boron can be changed to form a BPSG film, and the precipitation of phosphorus and boron can be detected visually. In addition, the flow rate of ozone during the formation of the BPSG film was kept constant (80 slm) in all samples.

[0156] P(wt%)

[0157] As shown in Table 1, in the BPSG film in which the total weight% of phosphorus and boron is 11% by weight, the precipitation of phosphorus or boron was confirmed within one day after the film formation. In addition, the inventors of the present application can confirm that as the total weight% of phosphorus and boron decreases, the time until the precipitation of phosphorus or boron gradually increases. In addition, under the condition that the total weight% of phosphorus and boron is less than or equal to 10% by weight, it takes 2 days or more than 2 days until phosphorus or boron is precipitated. Therefore, it ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com