Acid resistant zeolite adsorbent and preparation thereof

A technology of adsorbent and zeolite, which is applied in the field of acid-resistant zeolite adsorbent and its preparation, can solve the problems of uneven pore size distribution of coarse pores, reduce the use efficiency of adsorbent, and affect the strength of adsorbent, so as to achieve good acid resistance, high strength, Favorable Diffusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0018] Examples 1 to 4: Preparation of sodium zeolite powder crystals

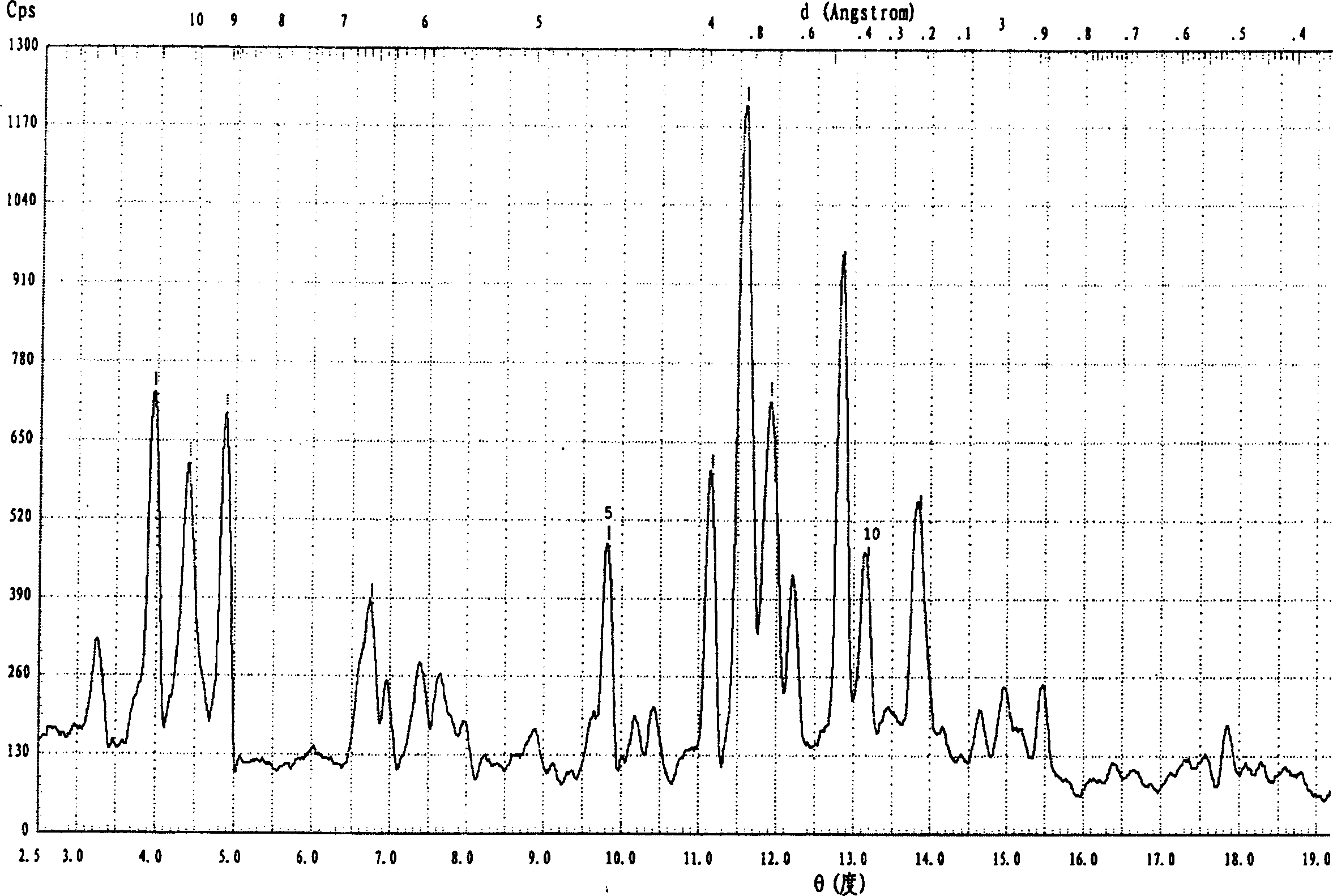

[0019] Weigh the water glass (its mass chemical composition (%)) according to the molar ratio of the reactants in Table 1 2 =25.33; Na 2 O=7.28), solid aluminum sulfate Al 2 SO 4 ·18H 2 O, sulfuric acid and water, after mixing, stir for 1-2 hours until uniform Na is formed 2 O-SiO 2 -Al 2 O 3 -H 2 O reactant colloid. The colloid is placed in a stainless steel autoclave, sealed, heated to a set temperature in a constant temperature oven, allowed to stand for a constant constant temperature reaction to a predetermined time, and the reaction kettle is taken out of the oven and cooled to room temperature. The reaction product is washed with deionized water, filtered, and dried. The crystal phase of the synthesized product zeolite was identified by XRD diffractometer. Except for the product of Example 4 which contains a small amount of quartz heterocrystalline phase, the other synthesized products are all pure phas...

Embodiment 5~7

[0021] Examples 5-7: Exchange of sodium ion zeolite for hydrogen production zeolite

[0022] Weigh 500 grams of the sodium-type zeolite synthesized in Example 2, and perform ion exchange with the acid (or ammonium salt) solutions listed in Table 2 in a stainless steel container to prepare a hydrogen-type zeolite. The exchange product is washed with deionized water to PH=6, filtered and dried. Analyze the Na of the obtained hydrogen zeolite 2 O content, the data are listed in Table 2, to prove that the exchange effect is good.

[0023] Example

Embodiment 8

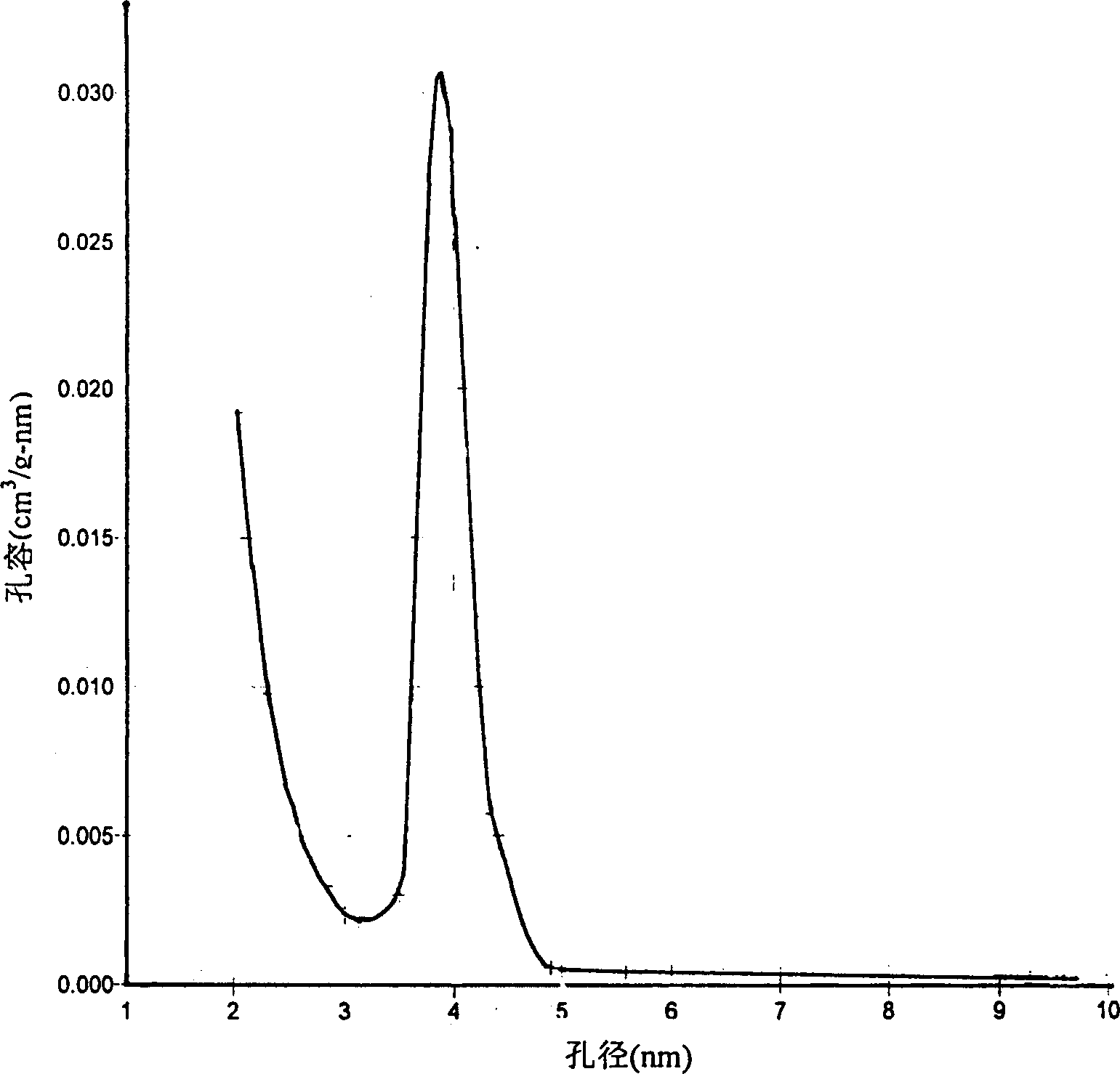

[0025] The preparation conditions of Example 5 were used to scale up and prepare 10 kilograms of hydrogen-type zeolite powder crystals. In the rolling ball forming machine, gradually add powder crystal and silica sol binder (containing 30% SiO 2 ) To make adsorbent pellets with a diameter of 1.5 to 2.2 mm. Calculated according to the amount of binder, in the prepared adsorbent pellets, on a dry basis, the amorphous silica binder / hydrogen zeolite = 0.2. After drying in an oven, the content of silica and alumina was measured, and the molar ratio of silica to alumina was calculated to be 22.8. The crushing strength of 50 pellets with a diameter of 2.0 mm was measured, and the average value obtained was 40 Newtons / particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com