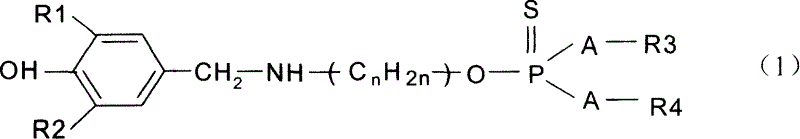

Anti-coking agent, and its preparation and use method

A coke inhibitor and reaction technology, applied in the field of new coke inhibitor, can solve the problems of poor thermal stability, single function of coke inhibitor, and decreased use effect, so as to achieve improved coke inhibitor effect, enhanced coke inhibitor efficiency, and simple and easy production. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

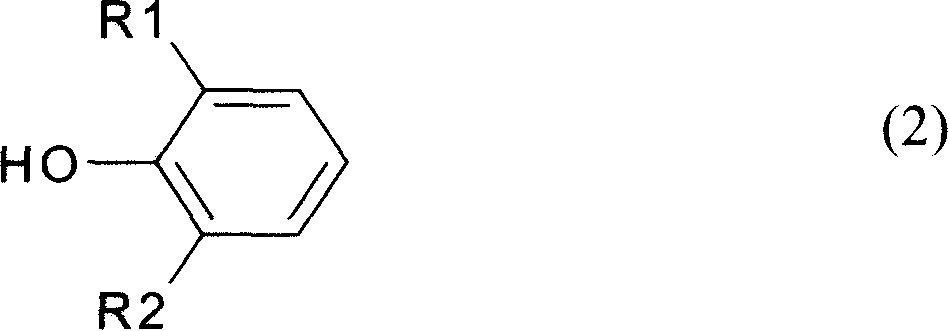

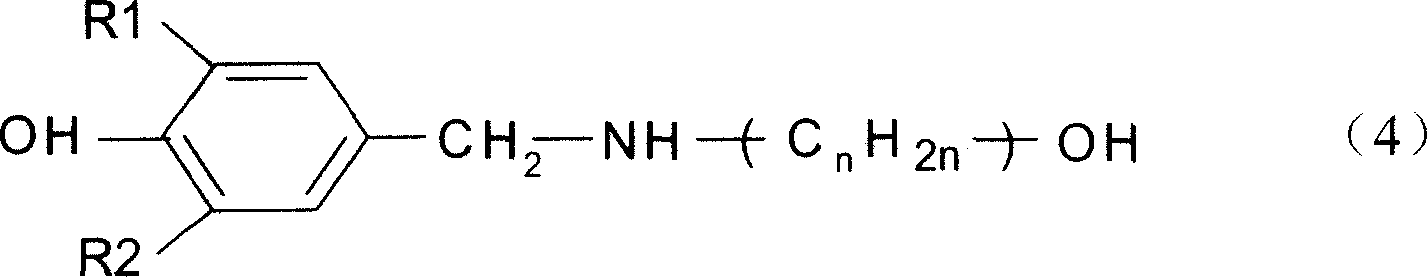

Method used

Image

Examples

Embodiment 1

[0040] Structures and preparation methods of novel compounds A1 and B1.

[0041] 1. The structural formula of novel compound A1 is formula (6), and the structural formula of B1 is formula (7):

[0042]

[0043] 2. Preparation method

[0044] (1) Add 24.4g 2,6-dimethylphenol, 12.2g monoethanolamine and 180ml xylene in a 500ml four-neck flask equipped with a stirrer, a thermometer, a water separator and a dropping funnel, start stirring, and put the oil bath heating. When the temperature rises to 92°C, formaldehyde solution (37-38%, 16.0g) is added dropwise, and the dropwise addition of formaldehyde is completed after 1 hour; the temperature rises to 120-150°C and reacts for 3 hours until no more water comes out of the water separator. Reaction product (theoretical amount 13.6 ml).

[0045] (2) Add 22.2g of phosphorus pentasulfide and 100ml of mixed xylene in the flask equipped with agitator, thermometer, and dropping funnel, start stirring, after heating to 60°C, start to...

Embodiment 2

[0047] Structures and preparation methods of novel compounds A2 and B2.

[0048] 1. The structural formula of novel compound A2 is formula (8), and the structural formula of B2 is formula (9)

[0049]

[0050] 2. Preparation method

[0051] (1) Add 41.2g 2,6-dibutylphenol, 12.2g monoethanolamine and 180ml xylene in a 500ml four-neck flask equipped with a stirrer, a thermometer, a water separator and a dropping funnel, start stirring, and put the heating. When the temperature rises to 92°C, formaldehyde solution (37-38%, 16.0g) is added dropwise, and the dropwise addition of formaldehyde is completed after 1 hour; the temperature rises to 120-150°C and reacts for 3 hours until no more water comes out of the water separator. Reaction product (theoretical amount 13.6 ml).

[0052] (2) Add 22.2g of phosphorus pentasulfide and 100ml of mixed xylene in a flask equipped with a stirrer, a thermometer, and a dropping funnel, start stirring, and after heating to 60°C, start to add...

Embodiment 3

[0054] Structures and preparation methods of novel compounds A3 and B3.

[0055] 1. The structural formula of novel compound A3 is formula (10), and the structural formula of B3 is formula (11)

[0056]

[0057] 2. Preparation method

[0058] (1) Add 44g of nonylphenol, 12.2g of monoethanolamine and 180ml of xylene into a 500ml four-neck flask equipped with a stirrer, thermometer, water separator and dropping funnel, start stirring, and heat in an oil bath. When the temperature rises to 92°C, formaldehyde solution (37-38%, 16.0g) is added dropwise, and the dropwise addition of formaldehyde is completed after 1 hour; the temperature rises to 120-150°C and reacts for 3 hours until no more water comes out of the water separator. Reaction product (theoretical amount 13.6 ml).

[0059] (2) Add 22.2g of phosphorus pentasulfide and 100ml of mixed xylene into a flask equipped with a stirrer, a thermometer, and a dropping funnel, start stirring, heat up to 60°C, then start to drop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com