Electrostatic self-assembly process of preparing multiple medicine controlled releasing coating in exponential increase characteristic

A technology of electrostatic self-assembly and exponential growth, which is used in drug combinations, pharmaceutical formulations, anti-tumor drugs, etc., to achieve the effects of simple process, increased drug loading, and simple loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

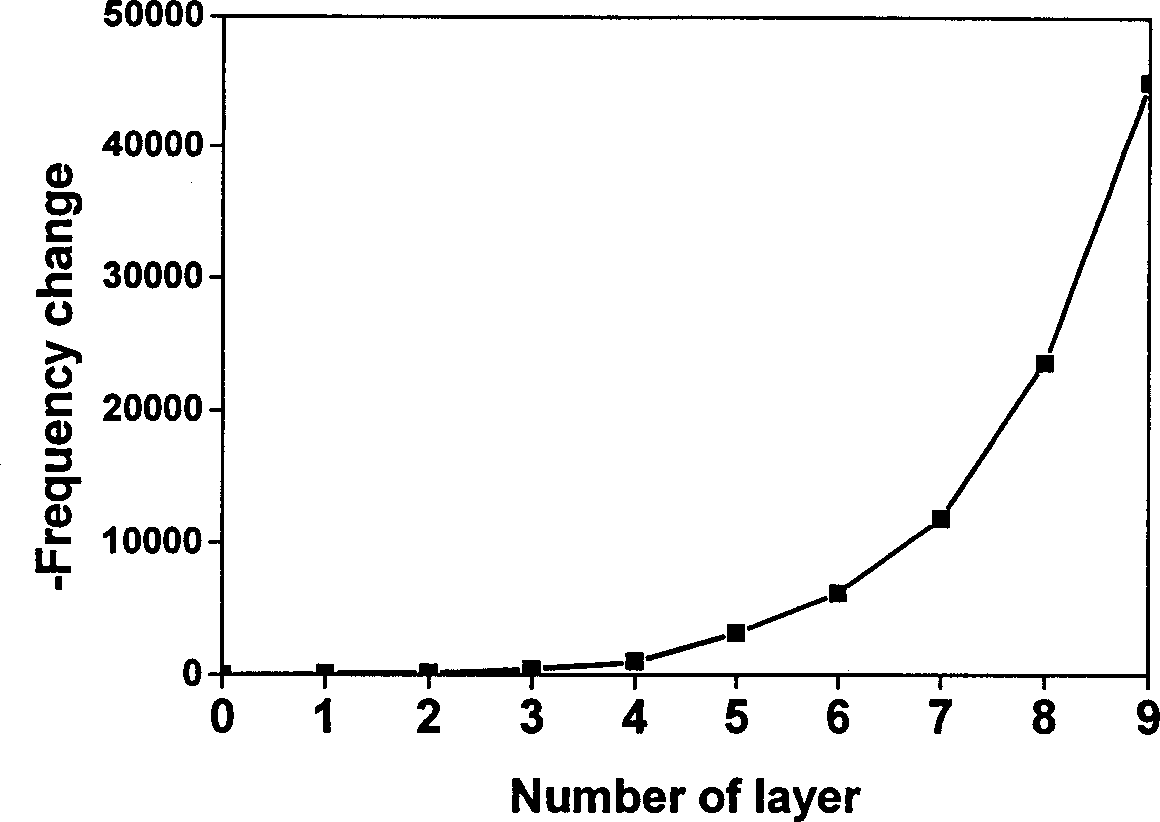

[0021] 1. For the preparation of multilayer films with exponential growth characteristics, first use various surface modification techniques to obtain a charged surface with positive or negative charges on the surface of polyurethane, polyvinyl chloride, polyester, silicone rubber or medical 316L stainless steel materials, The following weak polyelectrolytes are used for direct assembly, including one or more mixtures of polyethyleneimine, polylysine, chitosan, polyglutamic acid, hyaluronic acid, and sodium alginate. Using the electrostatic self-assembly method to alternately assemble on the medical device to obtain a multilayer film with exponential growth characteristics, the thickness can reach 0.1-120 microns in 10-50 alternating coatings.

[0022] 2 Multilayer film drug loading, immerse the prepared multilayer film with exponential growth characteristics in the charged drug aqueous solution with a concentration of 0.001mg / ml-10g / ml, adsorption equilibrium for 1-2000 minute...

Embodiment 1

[0025] First immerse the medical 316L stainless steel in 0.01-2mg / ml polyethyleneimine aqueous solution for 5-10 minutes, wash it with deionized water, and dry it with nitrogen to obtain the surface of polyethyleneimine physical adsorption, which is positively charged under the condition of aqueous solution . Soak the positively charged material above in 0.01-10 mg / ml sodium alginate aqueous solution for 5-10 minutes, wash it with deionized water, dry it with nitrogen, repeat the above process to obtain polyanionic sodium alginate and polycationic polyethyleneimine 2 -50 layers of alternating coating surface. Tracking with a quartz microbalance shows that the weight of the multilayer film assembly increases exponentially with the number of layers assembled. Ellipsometer measurements show that the thickness of the multilayer film can reach 0.1-20 microns within 20 layers. The multilayer film is soaked in 0.01-10 mg / ml aqueous solution of dexamethasone, which has an anti-stenos...

Embodiment 2

[0027] First immerse medical 316L stainless steel in 10-50mM polylysine aqueous solution for 5-30min, wash with deionized water, then blow dry with nitrogen, and then immerse in 20-40mg / ml polyglutamic acid aqueous solution for 20-30min Minutes, rinsed with deionized water, blown dry with nitrogen, and repeated the above process to obtain 2-80 layers of alternately coated surfaces of polyanionic polyglutamic acid and polylysine. Tracking with a quartz microbalance shows that the weight of the multilayer film assembly increases exponentially with the number of layers assembled. Ellipsometer measurements show that the thickness of the multilayer film can reach 20-100 microns within 50 layers. Immerse this multilayer film in the aqueous solution of 10-50 mg / ml small low molecular weight heparin, which has anticoagulant effect, for 30-60 minutes, and obtain the heparin release experiment of drug-loaded multilayer film, which shows that the multilayer film can be stable within 50 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com