Preparation method of dielectric film of aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and electrolytic capacitors, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of poor thermal stability, existence safety, and difficulty in using the electrolyte of electrolytic capacitors, etc., and achieves simple and easy preparation methods, good The effect of wide temperature range and liquid temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Anode foil in ionic liquid 1-ethyl-3-methyl-imidazolium tetrafluoroborate (referred to as EMI-BF 4 ) in the preparation method of forming dielectric film

[0026] (1) Pretreatment of the anode foil: the anode foil of the electrolytic capacitor is made of polycrystalline aluminum foil, the thickness of the aluminum foil is 0.1mm, and the purity is 99.9%. -1 NaOH, deionized water, 0.5mol·L -1 Soak in nitric acid and deionized water for 60 seconds in sequence, and the conductivity of deionized water is 0.06×10 -4 S m -1 Next, in order to remove moisture, rinse with methanol for 10 seconds to obtain a pretreated anode foil;

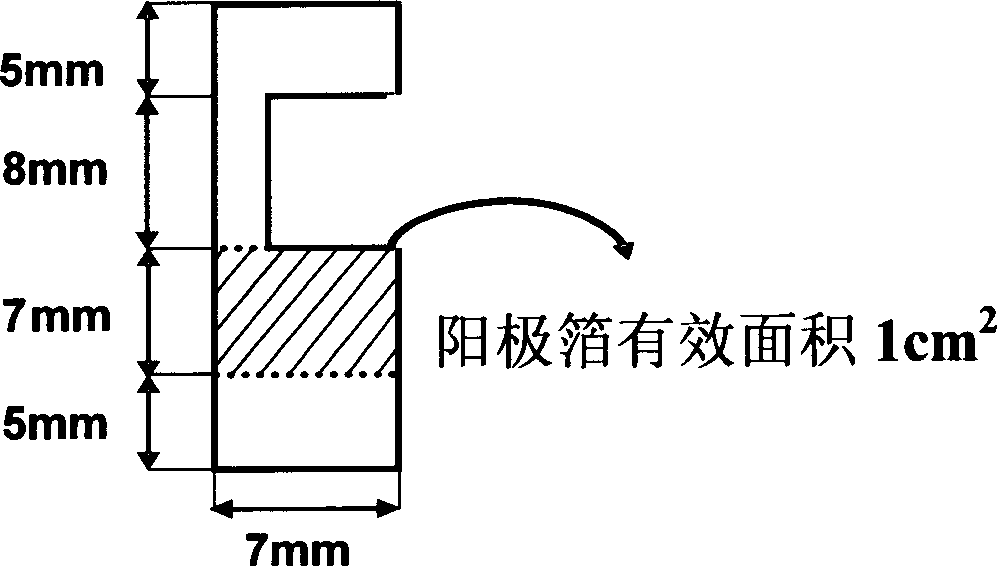

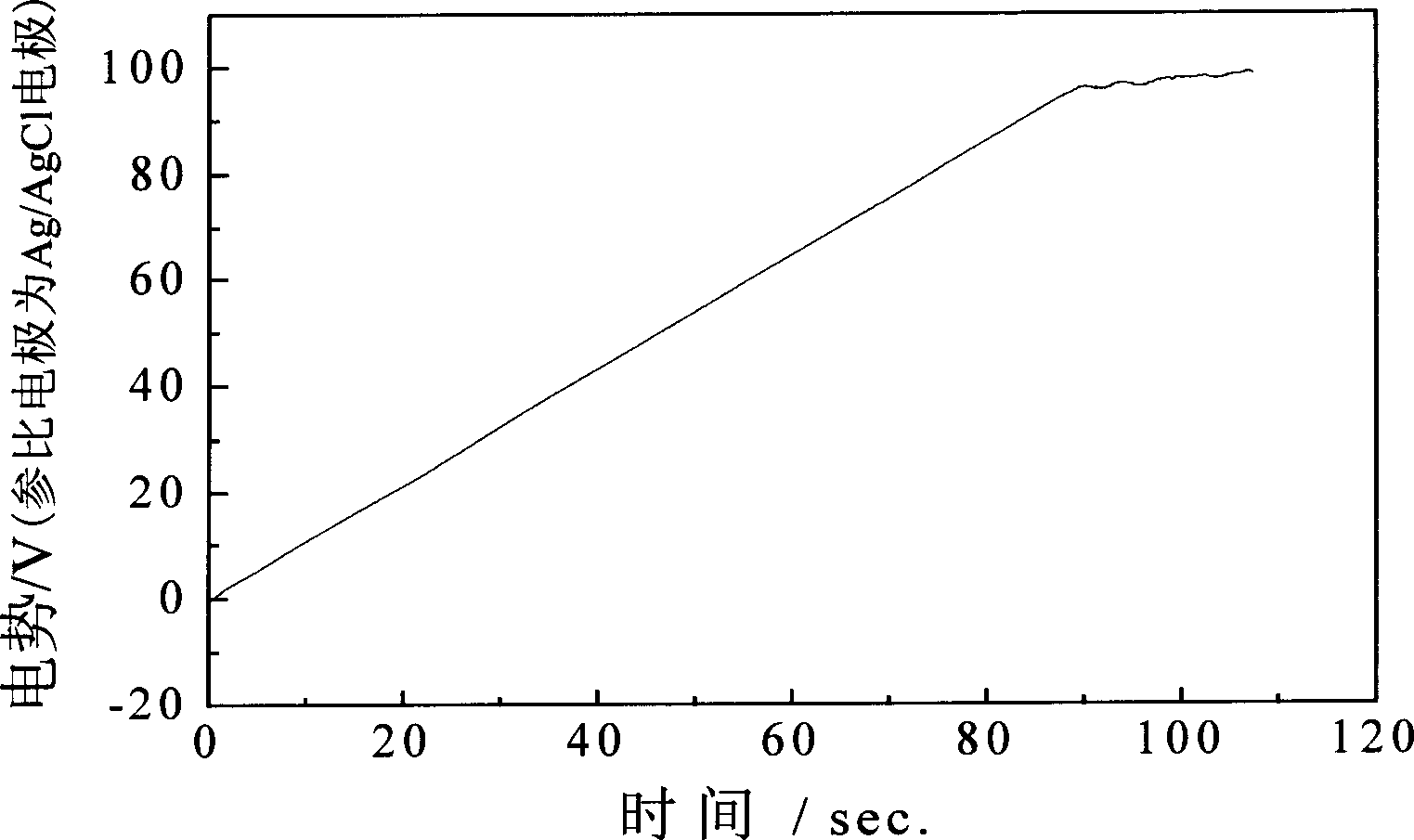

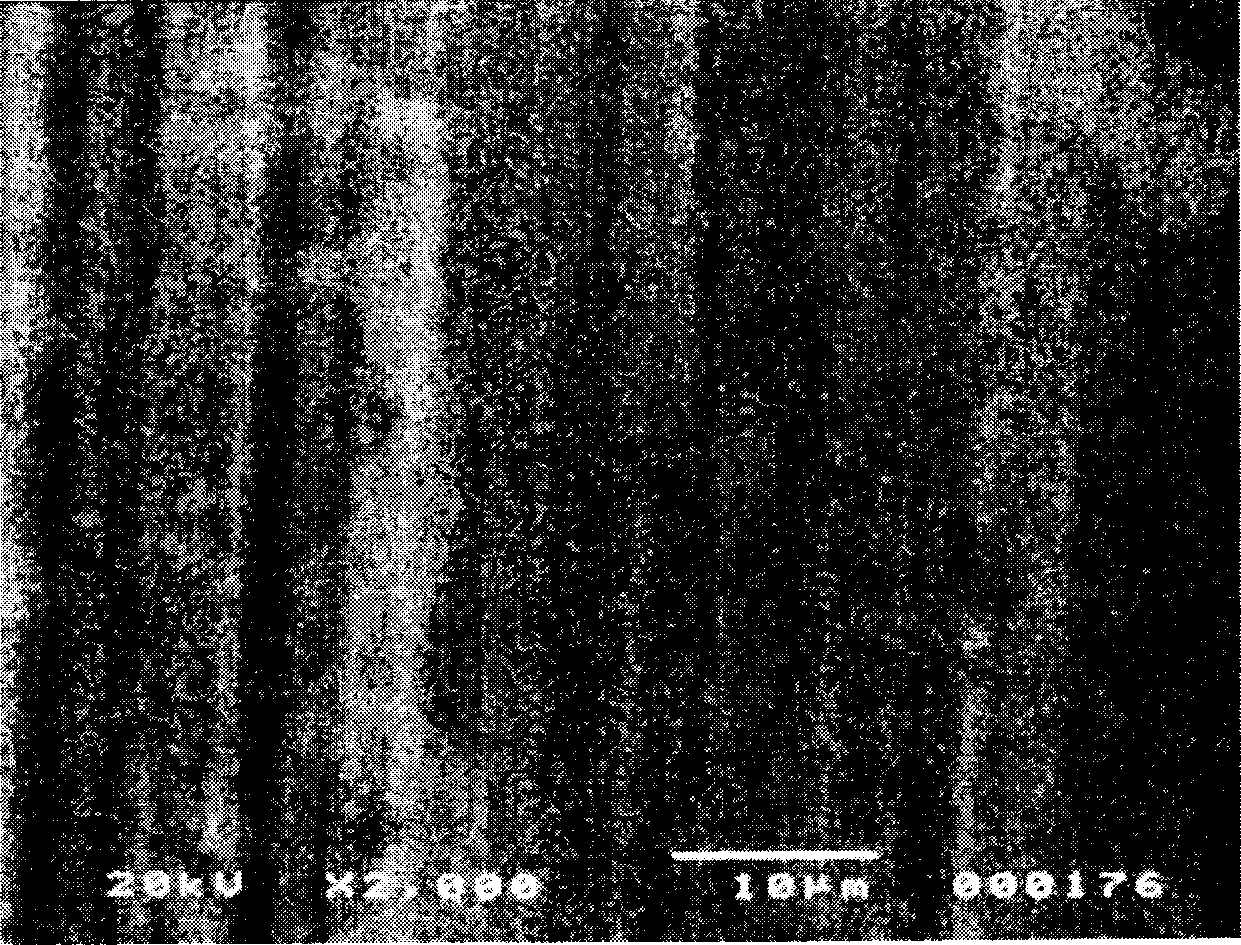

[0027] (2) Anode polarization of the anode foil: put the pretreated anode foil into a glove box, assemble a closed electrolytic cell, and the electrolyte is an ionic liquid 1-ethyl-3-methyl-imidazolium tetrafluoroborate (EMI- BF 4 ), its structural formula is as above table, the water content is 28ppm, the reference electrode is Ag / AgCl electrode,...

Embodiment 2

[0030] Anode foil in ionic liquid 1-propyl-3-methyl-imidazolium tetrafluoroborate (PMI-BF 4 ) in the preparation method of forming dielectric film

[0031] (1) Pretreatment of the anode foil: the anode foil of the electrolytic capacitor is made of polycrystalline aluminum foil, the thickness of the aluminum foil is 0.1mm, and the purity is 99.9%.-1 NaOH, deionized water, 0.5mol·L -1 Soak in nitric acid and deionized water for 60 seconds in sequence, and the conductivity of deionized water is 0.06×10 -4 S m -1 Next, rinse with methanol for 10 seconds to remove water to obtain pretreated anode foil;

[0032] (2) Anode polarization of the anode foil: put the pretreated anode foil into a glove box, assemble a closed electrolytic cell, and the electrolyte is ionic liquid 1-propyl-3-methyl-imidazole tetrafluoroborate (PMI- BF 4 ), its structural formula and water content are shown in the above table, the reference electrode is Ag / AgCl electrode, and the counter electrode is Pt e...

Embodiment 3

[0034] Anode foil in ionic liquid 1-butyl-3-methyl-imidazolium tetrafluoroborate (BMI-BF 4 ) in the preparation method of forming dielectric film

[0035] (1) Pretreatment of the anode foil: the anode foil of the electrolytic capacitor is made of polycrystalline aluminum foil, the thickness of the aluminum foil is 0.1mm, and the purity is 99.9%. -1 NaOH, deionized water, 0.5mol·L -1 Soak in nitric acid and deionized water for 60 seconds in sequence, and the conductivity of deionized water is 0.06×10 -4 S m -1 Next, rinse with methanol for 10 seconds to remove water to obtain pretreated anode foil;

[0036] (2) Anode polarization of the anode foil: put the pretreated anode foil into a glove box, assemble a closed electrolytic cell, and the electrolyte is ionic liquid 1-butyl-3-methyl-imidazole tetrafluoroborate (EMI- BF 4 ), its structural formula and water content are shown in the above table, the reference electrode is Ag / AgCl electrode, and the counter electrode is Pt e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com