Method for preparing biological flocculant using glutamic acid fermentation waste water

A biological flocculant and fermentation wastewater technology, applied in chemical instruments and methods, biological water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as environmental pollution, waste of valuable resources, etc. Realize the effect of fermentation cost and sulfate concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Specific Embodiment 1: In this embodiment, biological flocculants are produced by using glutamic acid fermentation wastewater according to the following method: a. Using straw cellulose biomass materials as raw materials, using a physical-chemical combination method for pretreatment to Improve the degradation rate of cellulose in the subsequent fermentation stage, that is: ① firstly crush the raw materials mechanically, ② treat with chemical reagents for delignification, and ③ steam and explode after treatment to further break the crystal structure and protective layer of cellulose molecules, so that The material becomes fluffy; b. Add glutamic acid fermentation waste water, prepare the culture medium, make the pH value to 7.0~7.5, add inorganic salt: 0.5~5g / L KH 2 PO 4 , 0.1~1g / L MgSO 4 ·7H 2 O, 0.1g / L NaCl, 0.01~0.05g / L FeCl 3 , 1.0~5g / L NaNO 3 to meet the nutritional requirements of microbial fermentation, wherein the raw materials account for 1 to 5% of the mass...

specific Embodiment approach 2

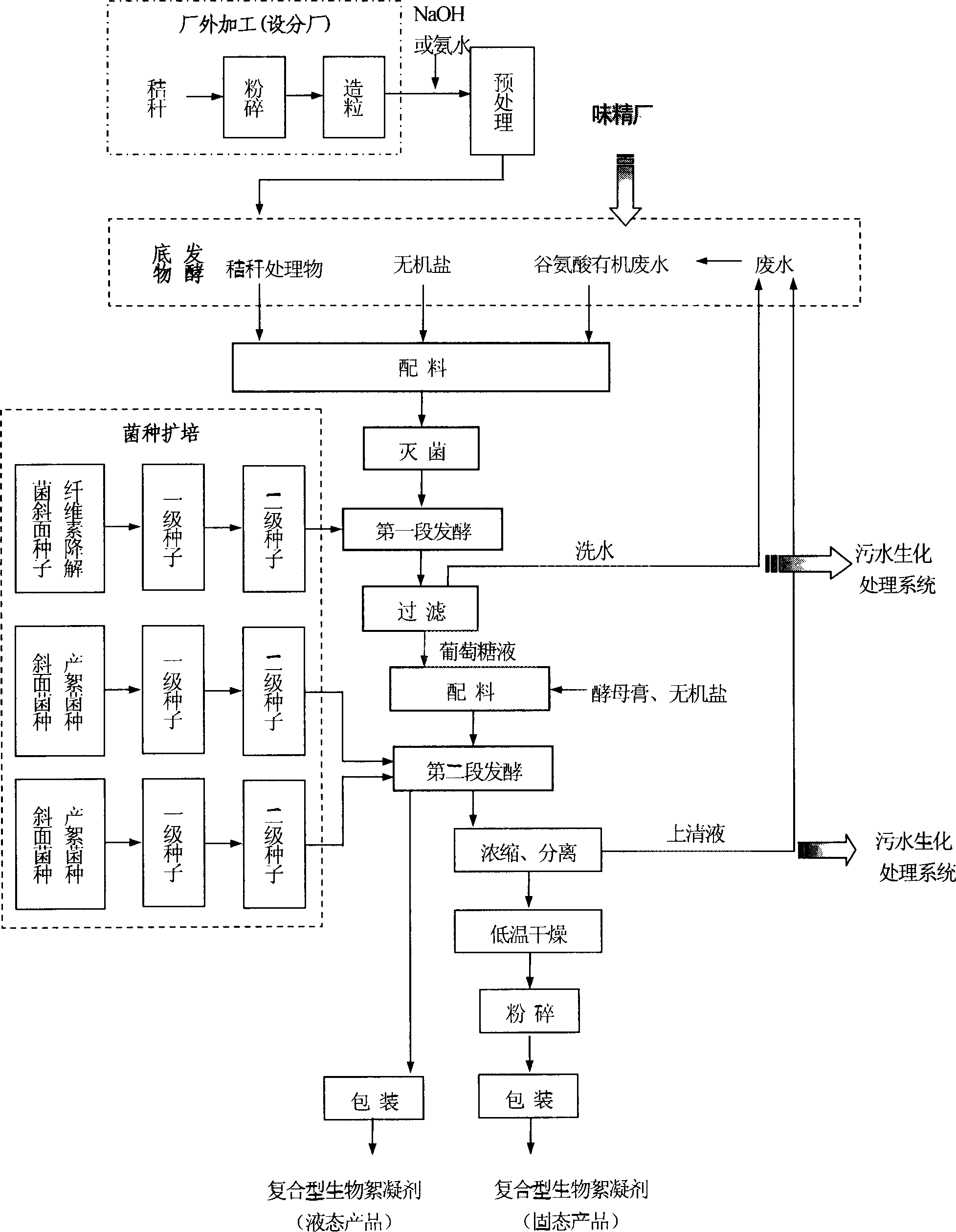

[0014] Specific implementation mode 2: This implementation mode takes glutamic acid fermentation waste water of a monosodium glutamate factory as an example, wherein the water quality of process drainage COD Cr =2500mg / L, BOD 5 =1200mg / L, SS≤300mg / L, TN≤200mg / L, pH=5.0~6.0; condensed water quality COD Cr =8000mg / L, BOD 5 =400mg / L, SS≤2000mg / L, TN≤300mg / L, pH=3.0~5.0, the water volume of both is the same. After the process drainage and condensed water are mixed and settled for 4 hours, straw treatment materials and inorganic salts are added according to a certain mass-volume ratio to make the pH = 7.0-7.5. The specific process is as follows figure 1 As shown, the processing effect is as follows:

[0015] (1) The pH of the straw treatment product obtained through pretreatment is 8.0-10.0, while the pH of the glutamic acid fermentation wastewater is 3.0-6.0. The two are mixed as the main component of the fermentation substrate, and the pH value is not adjusted using acid and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com