Polyether type polyurethane shoe sole and its preparation method

A polyether polyurethane and shoe sole technology, which is applied to shoe soles, footwear, footwear, etc., can solve problems such as harsh raw material grades and quality requirements, unsuitable for the production of ordinary polyurethane sole casting machines, and product quality differences, and achieves good results. The effect of hydrolysis resistance stability, good application and promotion prospects, good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

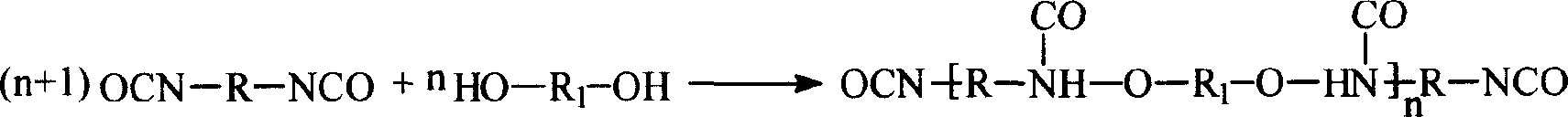

Method used

Image

Examples

Embodiment approach

[0037] A method for preparing polyether polyurethane shoe soles, which uses common polyether polyols as raw materials and adds filler modifiers to a mixed system formed of polyether polyols, chain extenders, water, surfactants and catalysts. The filler-modified component A is obtained, and the filler-modified component A is reacted with a prepolymer to prepare a filler-modified polyurethane shoe sole product.

[0038] The preparation method of filler modified component A is as follows:

[0039] Put the measured polyether polyol, chain extender, water, surfactant and catalyst into the mixing tank, raise the temperature to 40-50°C, stir and mix at this temperature for 0.5 hours, remove air bubbles, and obtain polyol Mix components. Then add calcium carbonate modifier in proportion, keep stirring for 0.5 hours. Then add the prepolymer components to the A and B material tanks of the shoe sole pouring machine respectively, and raise the temperature until the distribution ratio of...

Embodiment 1

[0041]Molecular weight is the common polyether polyol of 6000 trifunctionality, molecular weight is the common polyether polyol of 4000 difunctionality, ethylene glycol chain extender, water, surfactant (Dabco DC 3043), wherein weight ratio is 50: 50:6:0.7:0.3, pour into the mixing tank and stir for 15 minutes to form the polyol mixture component, and add calcium carbonate filler and catalyst with a particle size of 50-100nm in the polyol component in proportion, wherein the weight ratio is : calcium carbonate filler: catalyst (self-made catalyst, butanediol 25% solution of triethylenediamine): polyalcohol mixing component=5: 1.0: 100; 55 ℃ of stirring and mixing 1 hour, add the A batch tank of shoe sole pouring machine ; Add the prepolymer component with an NCO content of 23% to the material tank B of the shoe sole pouring machine, adjust the temperature of the material to 45°C, adjust the distribution ratio of the two groups close to the center point by adjusting the speed of...

Embodiment 2

[0043] Common polyether polyol with a molecular weight of 4000 trifunctionality, highly active polyether polyol with a molecular weight of 6000 difunctionality, 1,4-butanediol chain extender, water, surfactant (Dabco DC 3043) Put into the mixing tank, the weight ratio is 50:50:8.0:0.5:0.3. Particle diameter is that 100-200nm calcium carbonate and catalyst are added in the polyol component in proportion, weight ratio: calcium carbonate: catalyst (self-made catalyst, the butanediol 25% solution of triethylenediamine): polyol mixed component= 10:1.2:100; Stir and mix at 60°C for 1 hour, add to material tank A of the sole casting machine, add the prepolymer component with an NCO content of 20% to material tank B of the sole casting machine, adjust the material temperature to 45°C, By adjusting the speed of the metering pump, adjust the distribution ratio of the two groups to be close to the center point, so as to ensure that the isocyanate index is within the range of 95-105; appl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com