This error has two components, known as the accuracy error, and the

repeatability or reproducibility error.

Accuracy error, also referred to as Tool Induced Shift (TIS), directly arises from distortions and aberrations in the

optics of the

overlay metrology tool.

The

stepper must produce an overlay better than or within the overlay budget, however, the overlay

metrology tool must in turn, produce a

total error less than about one tenth of that.

This tight margin of

total error, especially the TIS component, translates to extremely strict requirements on the

optical quality of an overlay metrology tool.

Although features and objects, such as landscape and buildings, viewed by such optical equipment are relatively large, the large distances from which they are viewed result in minute details appearing in a viewed image, which can be thought of as scaling to similar conditions and dimensions involved in micro-

lithography.

Such optical elements cannot be rotated without affecting or changing the optical behavior of light or

radiation interacting with or passing through the optical element.

With regard to interaction of light with matter, the laws of

physics imply that, even if all basic components, such as lenses and mirrors, of an optical device or

system are perfectly designed, manufactured, and assembled, the optical device or system as a whole would still deviate from ideal desired optical behavior.

The problem with designing a more complex optical device, with the goal of achieving a better theoretical optical behavior, is that as the number of optical elements featured in an optical device grows, so does the probability for introduction of additional optical defects and deviations into the optical device, originating from the manufacturing and

assembly of additional optical elements.

No matter how much care and cost go into manufacturing individual optical elements of an optical device, such as glass lenses and mirrors, there are always found varying degrees of optical defects such as impurities, imperfections, and / or blemishes.

Moreover, every polished glass surface has some degree of deviation from the required shape, known as form errors.

In addition, individual lenses are usually covered with a

coating material, such as anti-reflective

coating, which introduces additional form errors and blemishes.

Performing

quality control inspection and testing on an optical device typically requires elaborate and time-consuming procedures, and even with sophisticated

testing equipment and

instrumentation, it is impossible to detect all defects.

Manufacturing costs and time involved in rejecting finished products failing specifications are extremely high.

The above described optical defects and deviations cause an optical device to deviate from its designed optical behavior, resulting in the occurrence of various aberrations and disturbances, such as

coma and

astigmatism, during real time application of the optical device.

Stopping down a lens

assembly may be quite acceptable for recreational or educational applications of optical devices, however, typically it is highly undesirable for applications in

leading edge technologies such as semiconductor fabrication.

During shipment, the optical device may be exposed to mechanical shock, severe pressure change if shipped by air, and severe temperature changes.

Thus, even following a comprehensive, costly, and quality controlled cycle of design, manufacture, and assembly, an optical device may still feature defects and / or deviations at the time of application by an end-user.

Unfortunately, this is never the case, since the components of an optical device, in general, and of an optical assembly or lens assembly, including optical elements such as lenses and / or mirrors, in particular, can never be perfectly manufactured, and assembled, for producing a perfectly functioning optical device.

Moreover, the presence of optical defects and / or deviations from ideal symmetry is likely to increase with increasing sophistication in the design of an optical device, as an increasing number of optical elements,

peripheral structures, and

peripheral mechanisms inherently leads to the presence of additional optical defects and deviations in the optical device.

Impurities or blemishes are randomly scattered throughout the

raw material, preventing the manufacture of a uniform glass or plastic, and hence preventing the achievement of circular symmetry of the optical element, and consequently, of the optical device.

However, such polished surfaces usually feature random locations of irregularities.

In addition, in a polished lens, there always exist form errors or shape irregularities, including symmetric and / or asymmetric form errors.

The common practice of plating an optical element with a

coating material, such as anti-reflective coating, introduces yet additional blemishes and form errors into the optical element.

The presence of these form errors and irregularities prevent the polished lens, and consequently, the optical device, from featuring a high degree of circular symmetry.

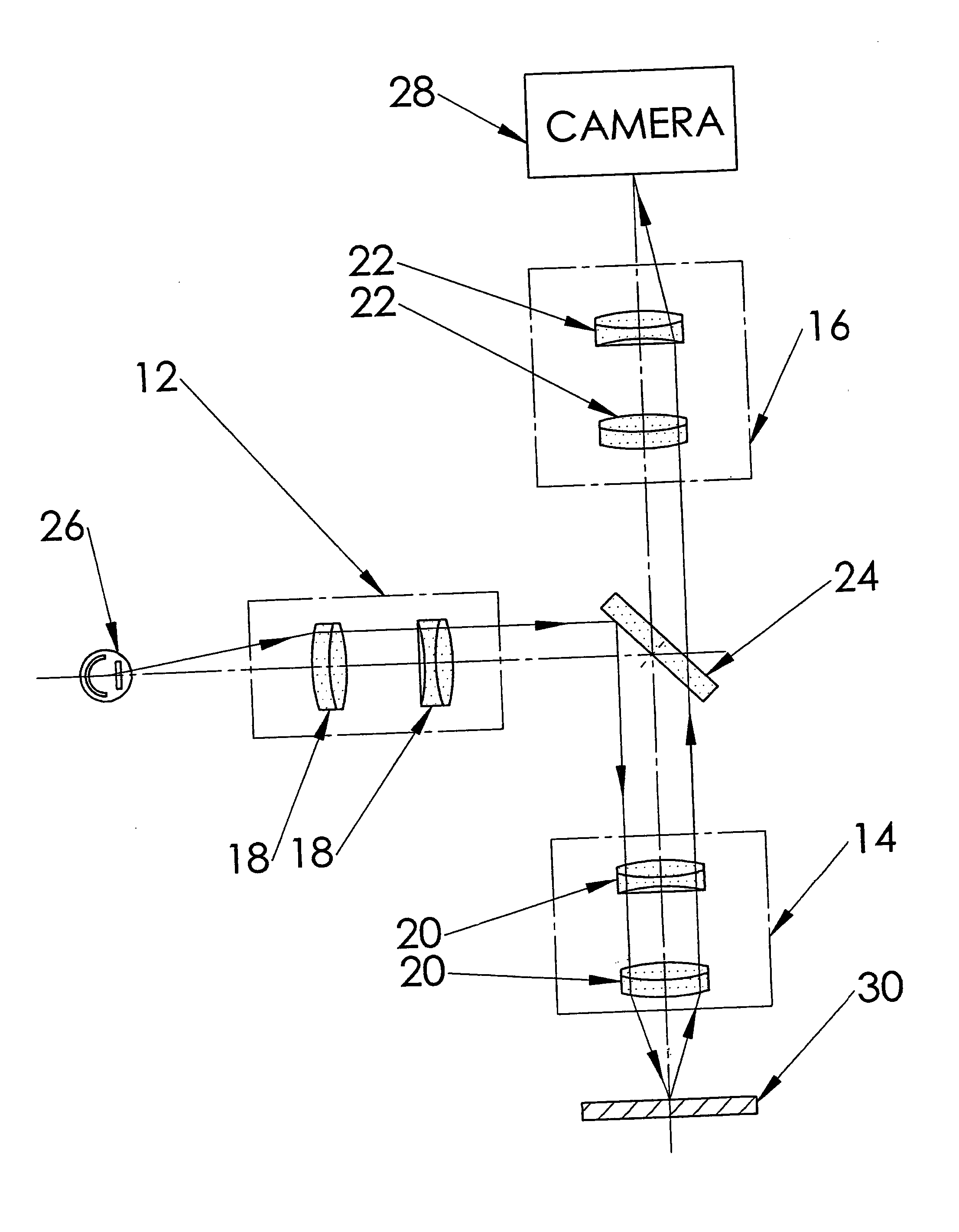

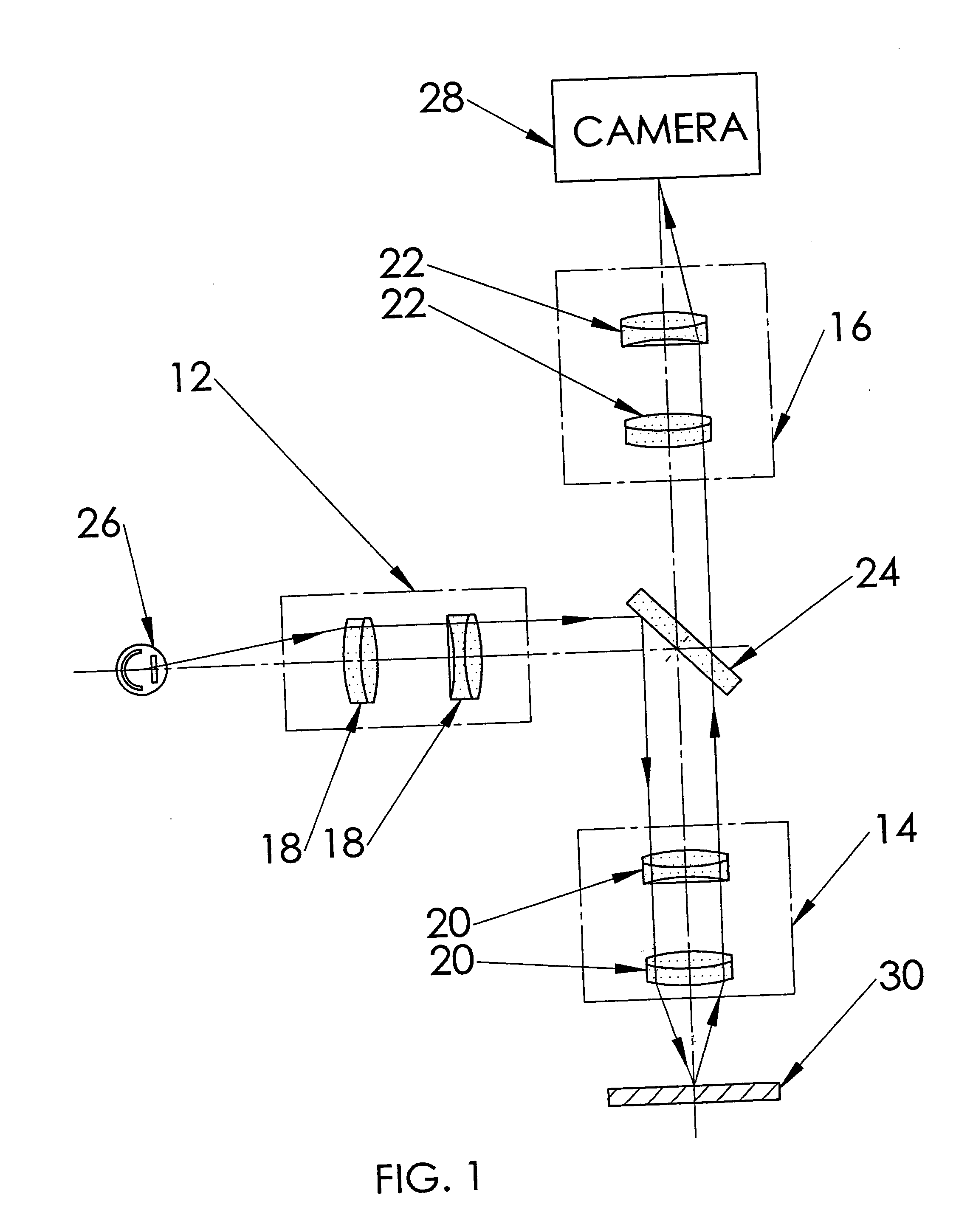

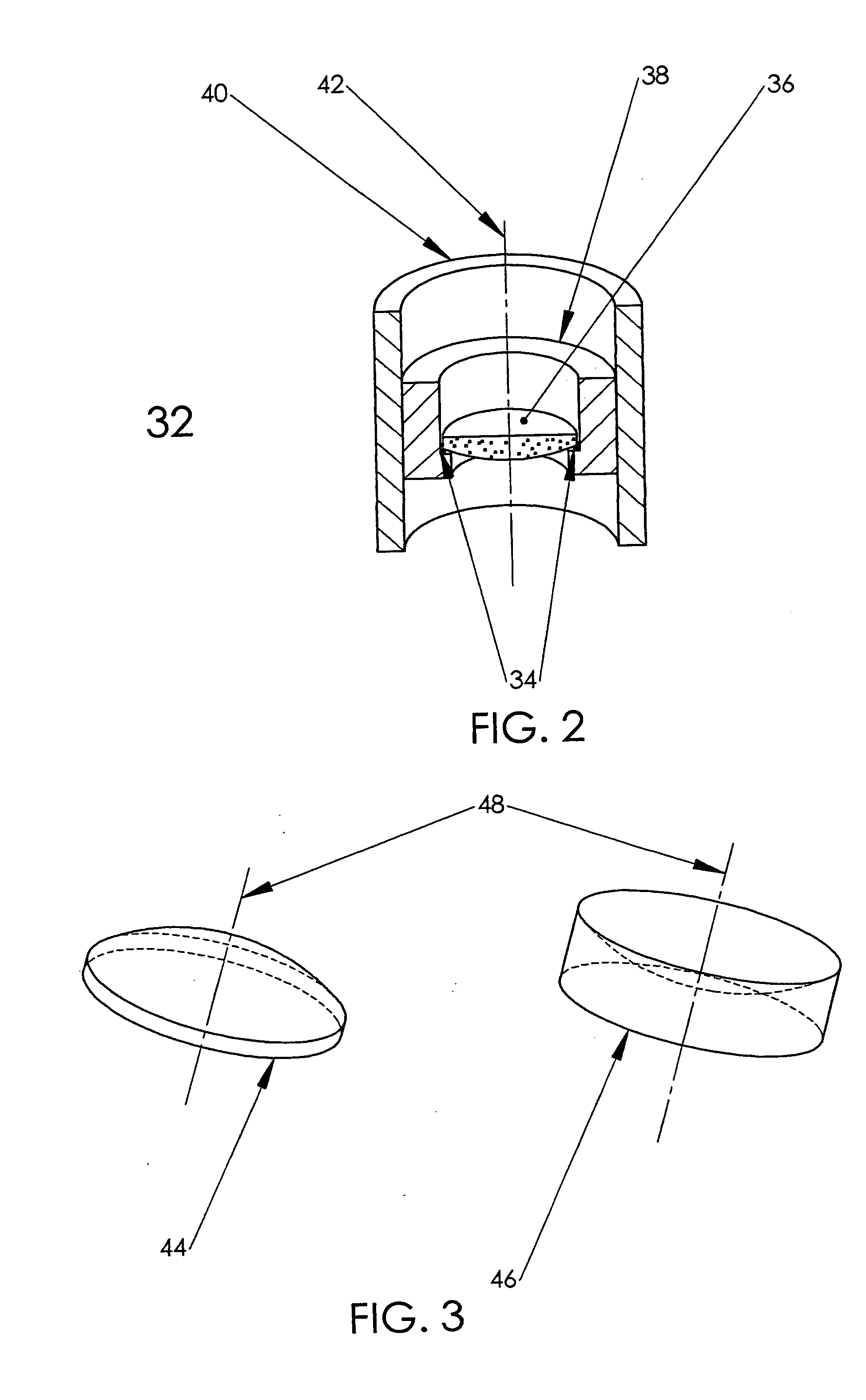

However, as described and shown in FIGS. 2 and 3, some combination of horizontal and / or angular deviations are inevitably present in the assembled optical device, thereby preventing the entire optical device, and not only the separate optical elements, from featuring circular symmetry.

For example, optical devices and systems including a

peripheral mechanism such as a

radiation source, in general, or a

light source, in particular, may be subject to further non-uniformities introduced by the source.

In general, it is desirable, but practically impossible, to obtain a source that produces

radiation of uniform intensity over the entire

field of view, or field of projection.

Integration occurring during

exposure time is usually considered in the art as very undesirable.

When taking a picture, for example, too long of an

exposure time, or, equivalently, too slow of an aperture speed, can cause blurring or smearing in images of an object.

In the Riggs disclosure, separate optical elements are mounted and separately rotated with different velocities, which places substantial mechanical complexity on such an apparatus.

Moreover, the fact that individual optical elements need to be separately handled, prohibits the use of proven, inexpensive and readily available

mass produced off-the-shelf sealed optical assemblies such as objectives, which ordinarily cannot be taken apart for facilitating approach to the individual optical elements.

The method thus forces the design, manufacturing, and assembly of totally new and unique optical assemblies, again placing substantial constraints on the practicality of the method.

Additional limitations apparent in the Riggs disclosure are that the method uses a series of separate exposures at time and rotation intervals, which is limited in its effect compared to a single

prolonged exposure which better ‘smears’ and diminishes the effect of optical disturbances, and there is not provided a means for aligning the

mechanical axis of rotation of the individual lens mounts with the

optical axis of the lens being rotated.

A general significant limitation of other prior art methods, is that they deal with effects of optical defects and deviations at the time of manufacture, assembly, and / or set-up of an optical device, for example, by translating, rotating, and aligning optical elements and / or assemblies of the optical device to an optimum configuration and performance level, immediately followed by permanently fixing, such as by cementing, the optical elements and / or assemblies, prior to release of the optical device to an end-user, or prior to use of the optical device by the end-user.

This procedure is very limited, since simple movements of one optical element usually cannot compensate for complex disturbances originating in other optical elements of the same optical device.

Any additional rotation would degrade the performance of the projection unit.

The method is limited by not providing means for correcting various types of optical disturbances, and may even lead to introduction of new systematic disturbances.

As described above, even after applying such devices and methods for diminishing effects of optical defects and deviations, there still remains

high likelihood of the presence of optical defects and deviations of the optical device by the time an end-user includes the optical device in an application.

In addition, following repetitive or modified use of an initially optimally configured and performing optical device, optical defects and deviations are expected to appear, thereby limiting further application of the optical device.

Login to View More

Login to View More