Three-dimensional profiling of photoresist with electron beam direct write on photoresist however is not cost effective for production quantities.

The tight thickness control necessary in the Iconel

evaporation steps makes this method of fabricating the gray level mask economically undesirable.

However, a half tone gray scale mask is not desirable due to limited resolution.

However, in this case no mask is created.

Namely, it is not cost effective for making microoptical elements in production quantities using this direct write method.

However, one

disadvantage of this technique is the cost of the mask generation, wherein multiple direct write steps on photoresist are required to provide the

lift off process of the light absorbing material for each discrete thickness desired.

The tight thickness control necessary in the material

evaporation steps makes this technique economically undesirable.

The gray scale photomasks described above cannot be utilized for the fabrication of high quality micro-optical elements in production quantities, because of their failure to satisfy either one or both of the following requirements: 1.) a sub-

micrometer gray scale resolution element, 2.) acceptable cost in the mask generation.

However, the HEBS-glass plates of Wu patents did not satisfy the second requirement listed in the

paragraph immediately above.

This is expected because there is not a development step for the HEBS-glass to enhance the contrast of the e-beam exposure induced

optical density.

E-beam writers are very expensive, the write time of a mask has to be in the order of minute or hours, not days, otherwise there would be little economic value.

However, flood e-beam exposure

system, which is much less expensive, is not an option for making a

photomask for the following reason.

EVC

Electron Cure systems has no capability of delivering an e-beam dosage having a predetermined functional variation in x and y coordinates.

Moreover, there exists no fixture in EVC

Electron Cure

system for precision movements of an aperture in the X-Y plane to create a mask patter.

This method is not applicable and is undesirable for making a HEBS-glass gray scale

photomask for the following reason.

During the months of March and April of 1987, Motorola, one of the world's largest manufacturers of integrated circuits (i.e. IC chips), evaluated the HEBS-glass plates of Wu patents for use as a binary mask for IC photomask applications and concluded that HEBS-glass plates of Wu patents require too much e-beam write time creating a high cost of mask generation.

This exposure scheme is impractical for making HEBS-glass gray scale photomasks.

The cost of e-beam write time, e.g. 1,000,000 hours to write 1 plate clearly prohibits the use of a HEBS-glass plate of Wu patents to make a gray scale photomask.

Besides the prohibitive cost, the

technical feasibility of making a HEBS-glass gray scale mask is doubtful due to the properties of HEBS-glass described immediately below:

Due to the intermittence effect, exposure schemes with multiple retraces is complicated by the additional variable parameter, the intermittence

time duration.

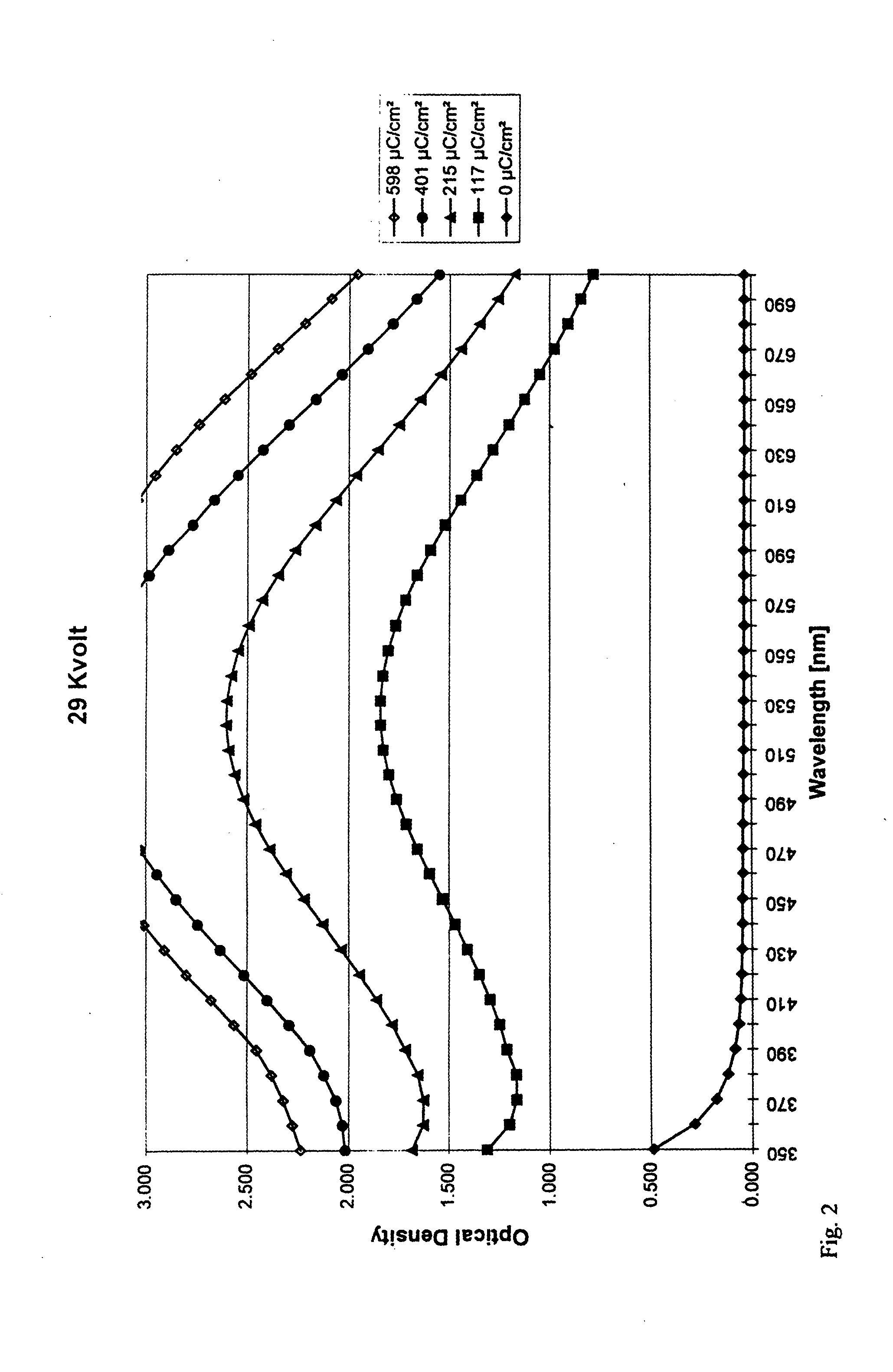

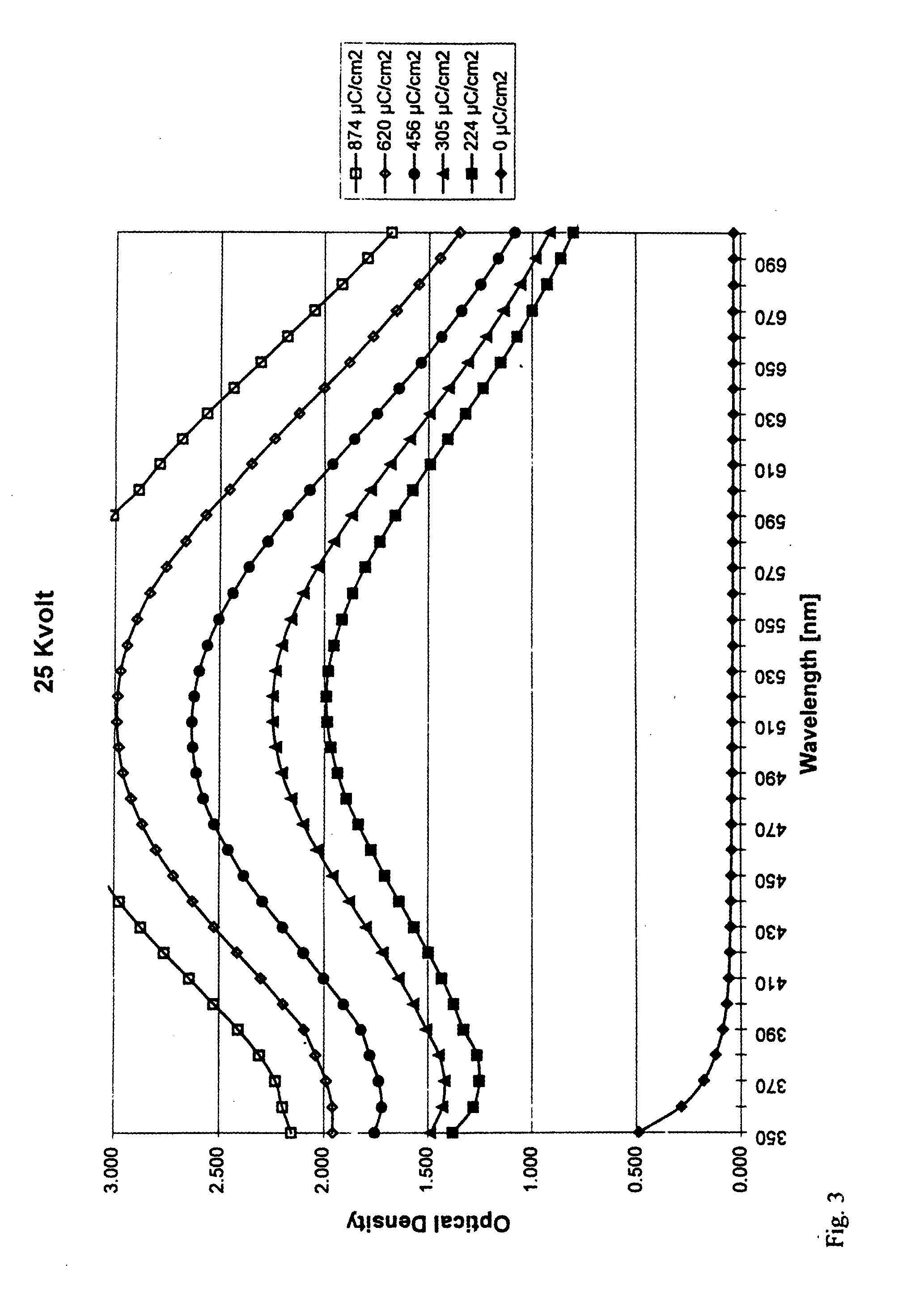

However, for the fabrication of HEBS-glass photomasks, an exposure scheme utilizing a variable

shaped beam does not produce a constant value of e-beam induced

optical density in HEBS-glass for a constant e-beam exposure dosage, particularly when a high e-

beam current density is used.

MEBES e-beam writers, the only e-beam writers commercially available for mask writing service, do not provide a practical exposure scheme for making HEBS-glass gray scale masks.

This e-beam writer is a research tool and is not available in commercial mask shops for IC photomask fabrication.

The write parameters necessary for producing the combined effects of this application has never been and can never be applied to

expose electron beam resists for which the e-beam writers were designed.

There is no other product, apparatus, or method that could produce such a gray scale mask at the cost of a HEBS-glass mask.

A large portion of the e-beam write time is consumed by data loading since circular patterns with a large number of gray levels require a very large

data file.

Diffractive optical elements such as spherical, cylindrical, Fresnel lenses, aspherics and other micro-devices having rather precise three dimensional profiles or contours present certain problems with respect to volume production of these elements of an acceptable quality, in particular.

The fabrication of large arrays of such elements covering large areas is very costly with regard to known

methods of production.

The fabrication of a master or individual elements using a multi-binary mask method can result in significant dimensional errors in the master and the fabricated element due to residual alignment errors between consecutive masking steps.

Although

diamond turning, for example, can be employed in producing a mater element, the multi-binary mask technique is limited with symmetric elements, for example.

However, the materials used in these techniques have limited optical and environmental properties, and are, for example, operable to be transmissive to

radiation only in the spectral range visible to the

human eye.

However, the

high resolution required of diffractive optical elements and other micro-elements is limited with this technique due to the limited resolution of the

laser writer and the graininess of the image on the

emulsion based mask.

Moreover, photographic emulsions are not particularly durable and do not allow cleaning of the mask with water or mechanical scrubbing.

Other gray scale masking techniques, including the so-called half tone binary mask, are also limited due to the small holes in the mask which will also diffract light passing through the mask, further limiting the resolution of the desired diffractive optical element, for example.

However, one

disadvantage of this technique is the cost of the mask generation method wherein multiple direct write steps are required to provide the

lift off process of the light-absorbing material for each discrete thickness desired.

The tight thickness control necessary in the material evaporation step makes this technique somewhat economically infeasible for many applications.

Login to View More

Login to View More