Composite for Thermo-Sensitive Cell-Tissue Transplanted Scaffold and Use thereof

a technology of thermosensitive cells and scaffolds, applied in the field of composites for thermosensitive celltissue transplanted scaffolds, can solve the problems of unsatisfactory commercialization of the above-mentioned technology, the limitation of the amount of available skin, and the possibility of donor site morbidity and other problems, to achieve the effect of convenient stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Materials and Methods

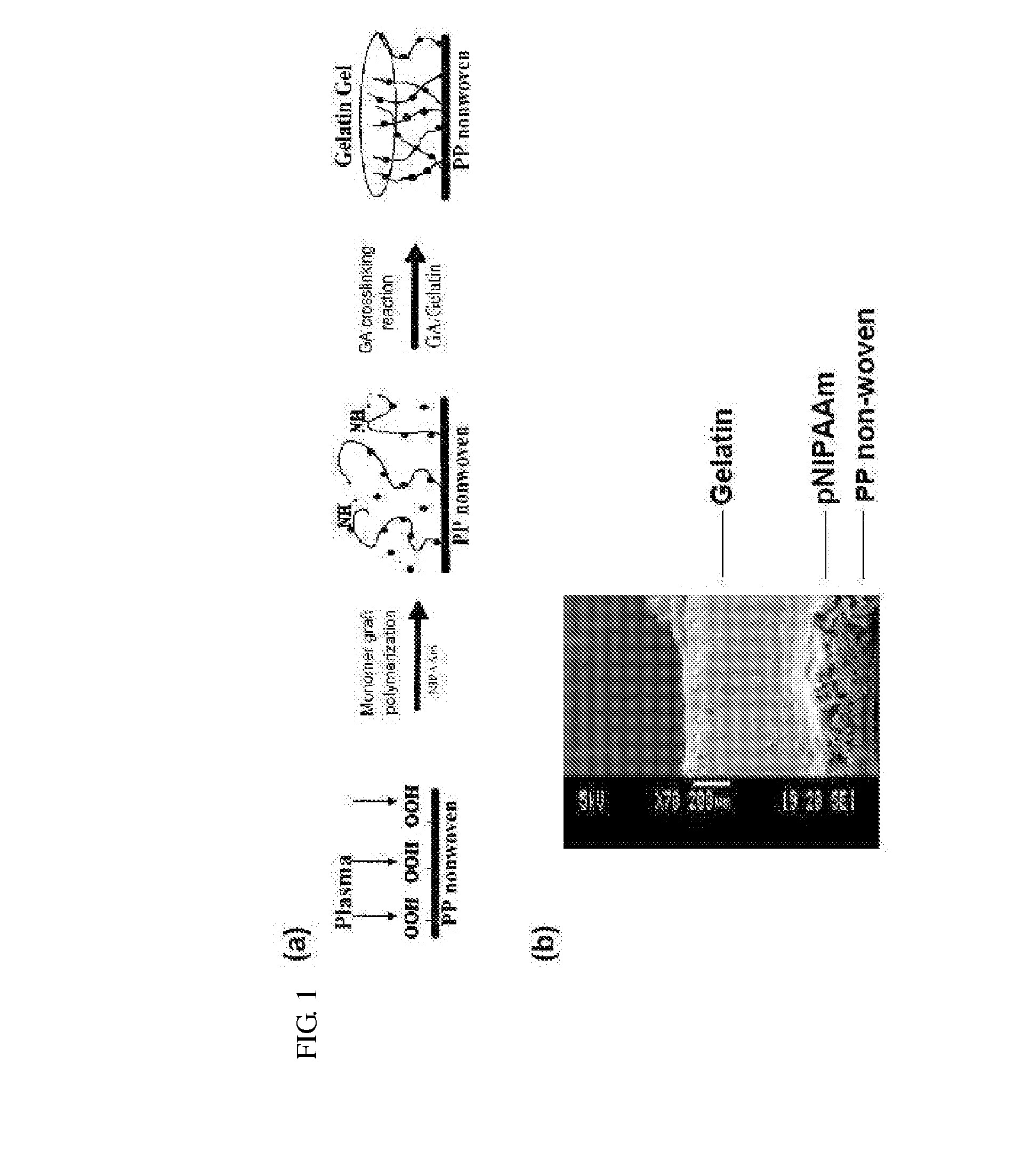

[0054]Preparation of Easy-Peeling Scaffold

[0055]Polypropylene (PP) non-woven was cut into strips (2×3 cm2and washed in distilled water and the 95% ethanol solution. The N-isopropylacrylamide (NIPAAm) was supplied by Eastman Kodack Co. Ltd USA; the ammonium persulfate (APS) was purchased from Wako Pure Chemical Industry Co., Ltd. The N,N,N′,N′-tetra-methylethylene-diamine (TEMED) was purchased from Fluka and N,N′-methylene-bis-acrylamide (NMBA) from Sigma. Other agents or drugs were all of chemical grade. The PP nonwoven was placed into a plasma treatment system with a rotating substrate holder. Then the graft polymerization of the 10 wt % NIPAAm solution was carried out with a 1000 W UV light irradiated for 30 minutes. The NIPAAm-grafted PP non-woven was chemically crosslinked in gelatin solution by the GA crosslinking agent. The NIPAAm-grafted PP non-woven was placed into a −80° C. refrigerator for three hours and further placed into a freeze-dryer for 1-2 days...

example 2

Easy-Peeling Scaffold Property Evaluation

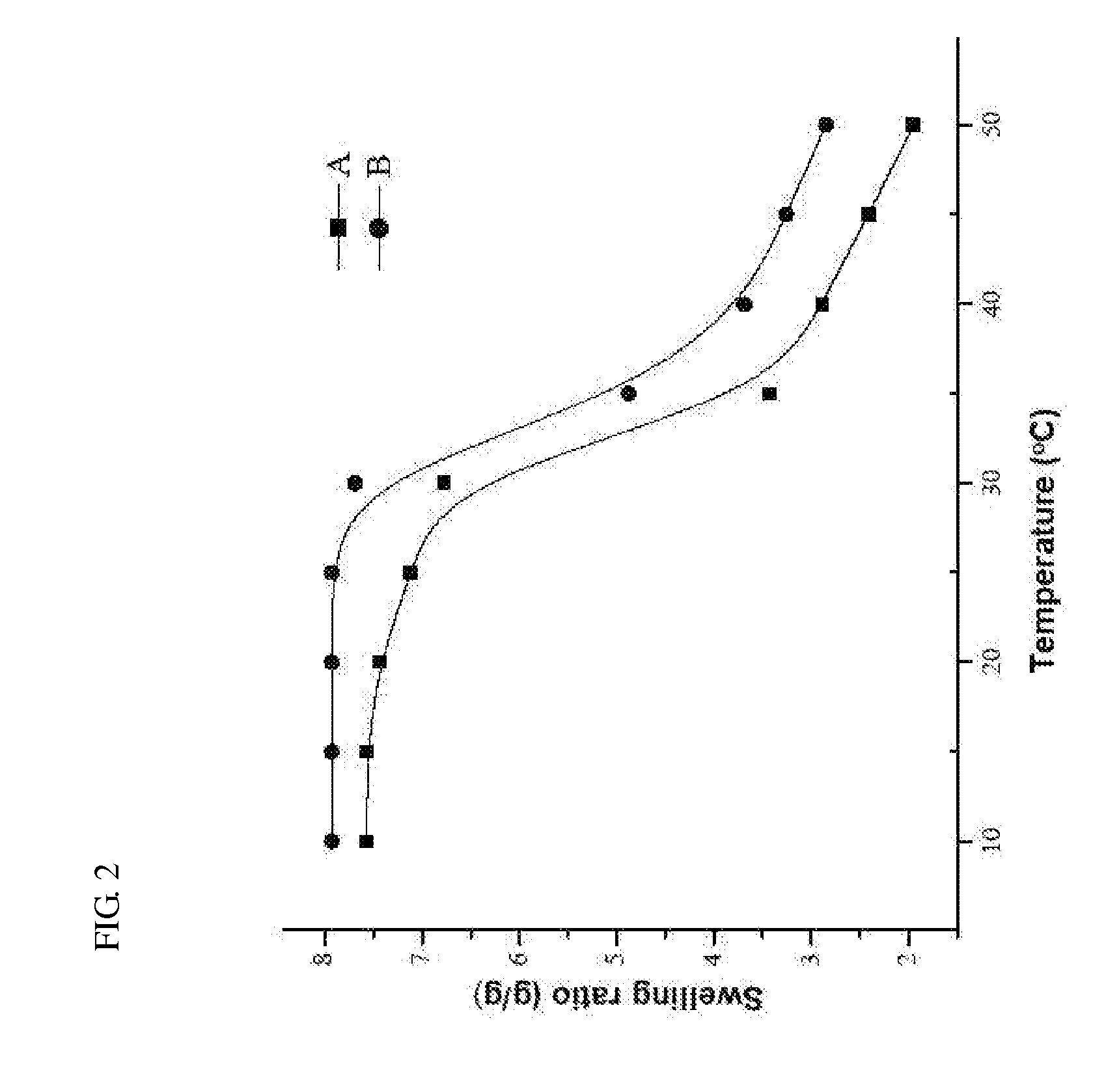

[0071]As showed in FIG. 1(b), the composite of the trilayer (gelatin / pNIPAAm / PP non-woven) cell-transferred scaffold was demonstrated by scanning electrical microscope. As showed in FIG. 2, the thermo-sensitive response behavior and swelling ratio variation between the pure pNIPAAm hydrogel and the trilayer scaffold showed a similar trend. Furthermore, they all revealed the equivalent lower critical solution temperature (LCST) point at around 32° C. It demonstrated that the pNIPAAm hydrogel exhibited its temperature-sensitive property even if it was grafted onto the surface of different substrates. The trilayer scaffold after the freeze-dried treatment exhibited the higher force (57 Newton) for PP mesh being separated from the scaffold. When immersed this composite in room-temperature water for 2-3 hours to the swelling state, the strip-off force decreased to 1 Newton. However, when it was put in hot water (>34° C.), the force increased to 7 ...

example 3

Bone Marrow Stem Cells (BMSCs) Culture

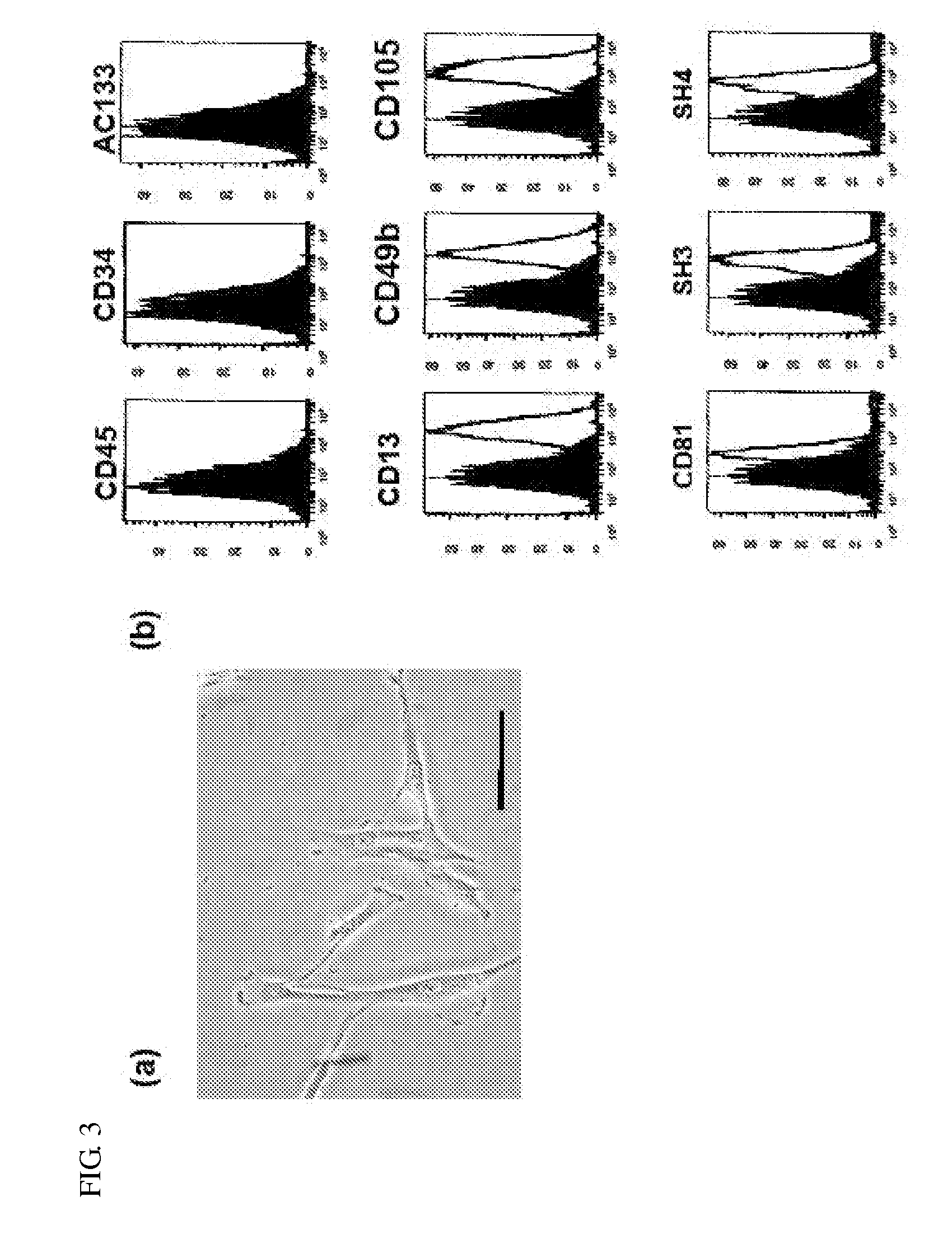

[0072]As showed in FIG. 3(a), the protocol for isolating the hBMSCs from fresh human BM of five donors was used. hBMSCs usually appeared as spindle-shaped cells with scant cytoplasm and had granules around the nuclei. Within 7 days, the cultures of hBMSCs were nearly confluent and were passaged at 1:3. As showed in FIG. 3(b), the flow cytometry analysis revealed that the hBMSCs were strongly positive for CD13, CD49b, CD105, CD81, SH3, and SH4, but negative for CD45, CD34, and AC133. As showed in FIG. 4, the hBMSC morphology and phenotype remained unchanged for more than 30 cell passages [n=5]. To further monitor the tumor cell proliferation in vitro and in vivo, GFP gene was transduced into hBMSCs using MSCV. As showed in FIG. 5(a), the GFP-positive hBMSCs (hBMSCs-GFP) were then sorted by flow cytometry. The hBMSCs-GFP stably passaged and expressed the markers of mesenchymal stem cells to 30th passage (Table III).

TABLE IIIThe percentage of immun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com