Broad speed range generator

a generator and wide-range technology, applied in the direction of electric generator control, machine/engine, dynamo-electric converter control, etc., can solve the problems of inability to use a series low-loss ferrite core inductor, inability to regulate the power of the induction machine,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

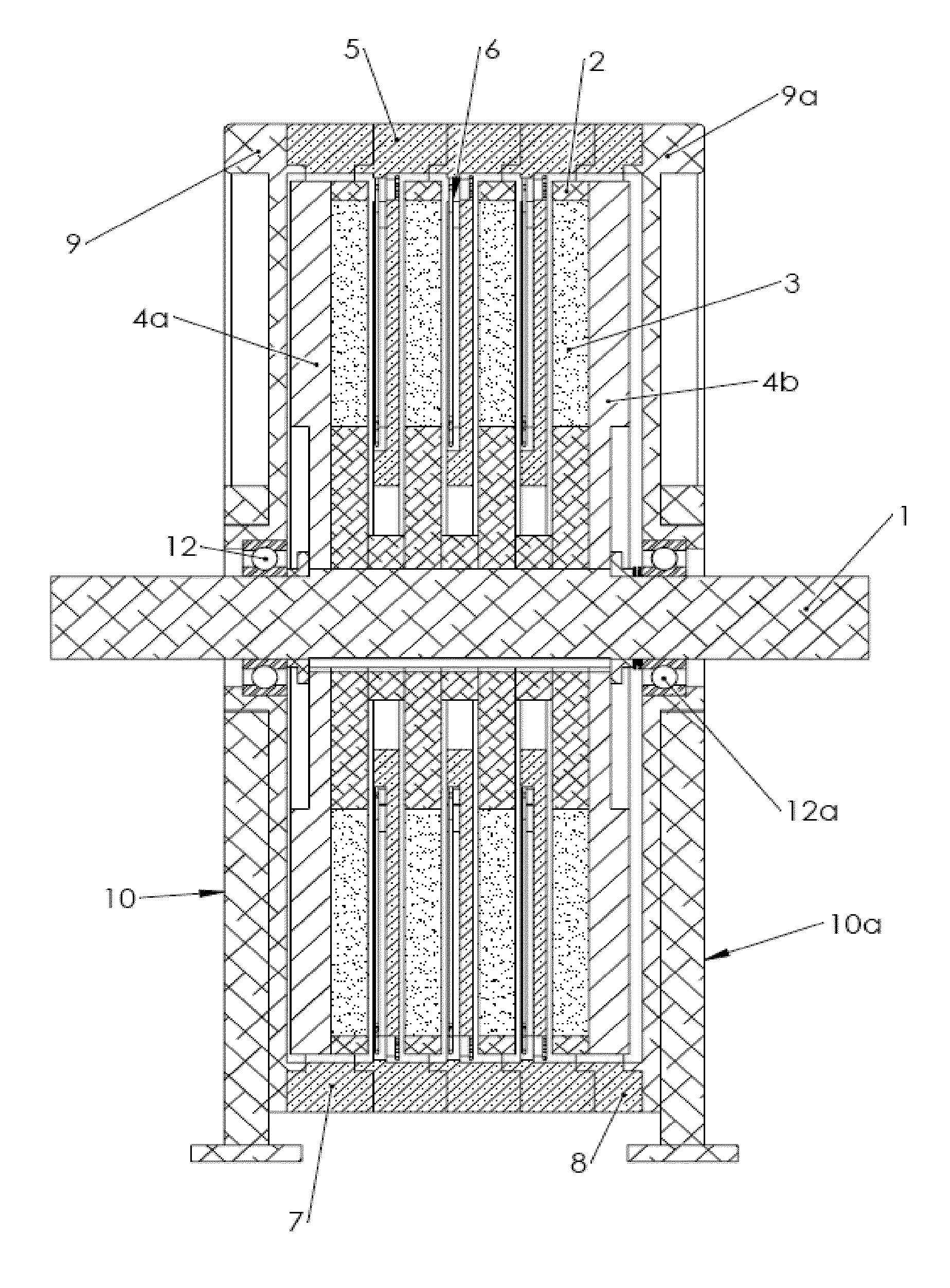

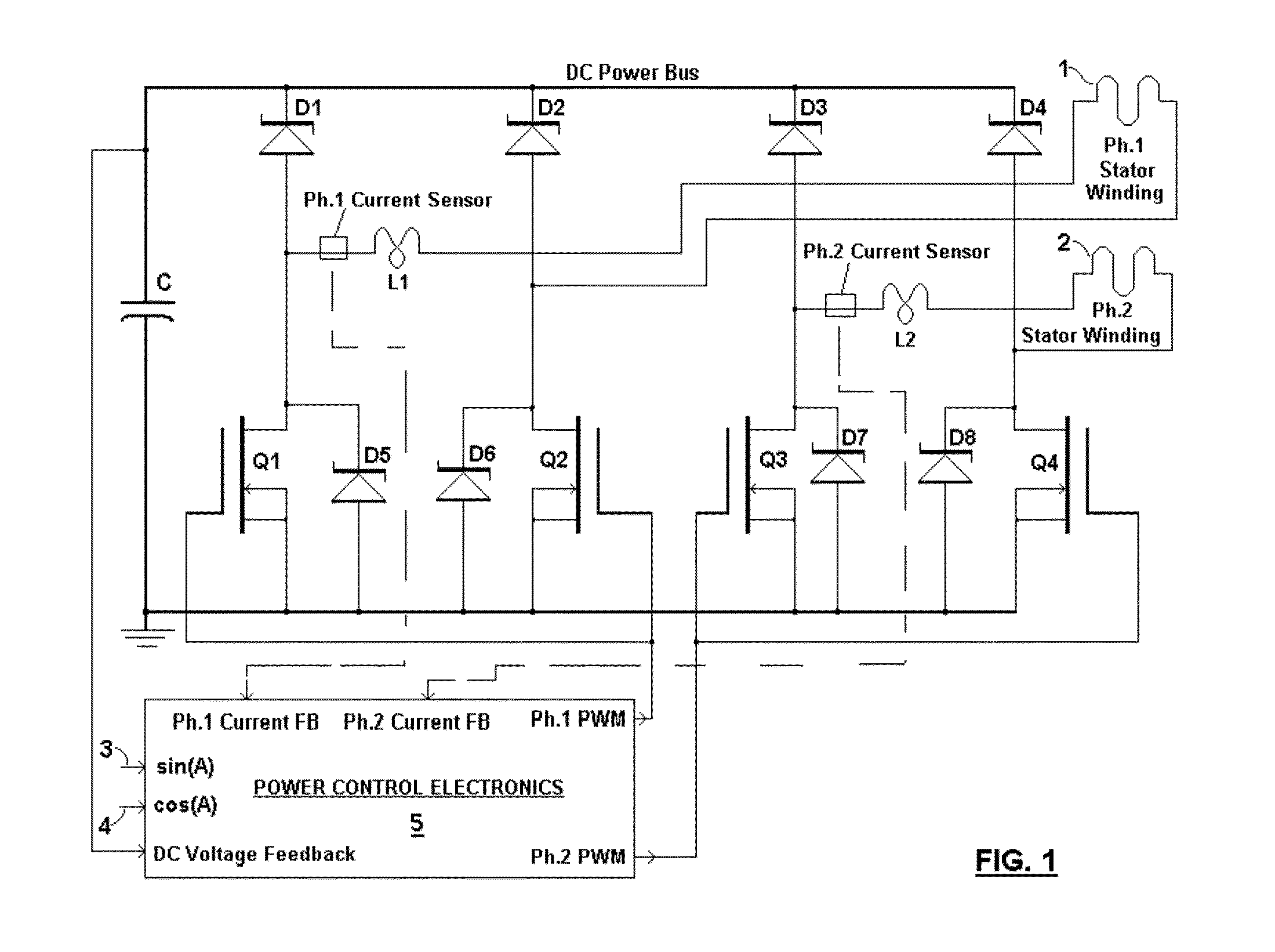

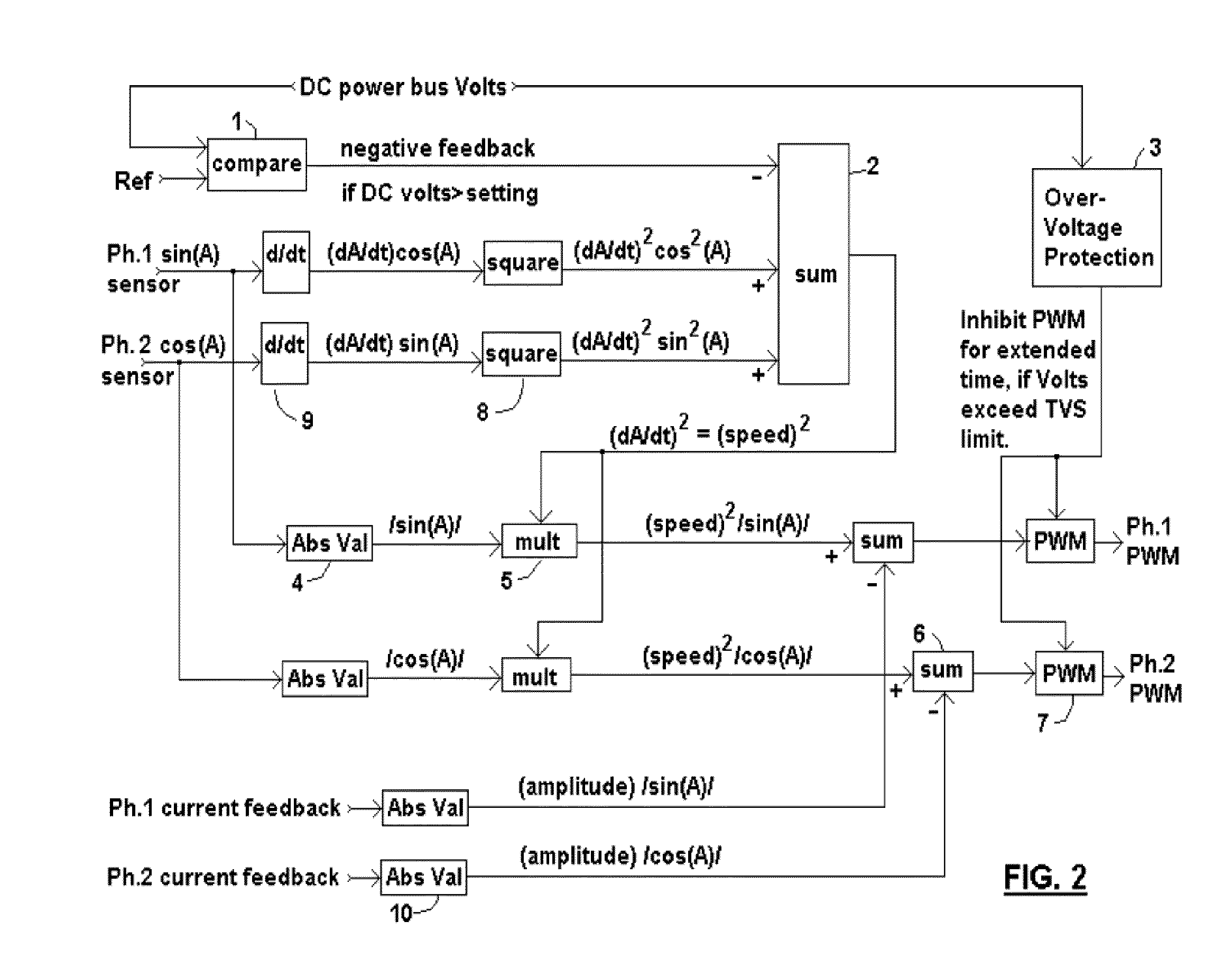

[0063]Main elements and combinations of this new generator are set forth herein and illustrated in FIG. 1. This invention implements a new cooperative combination of elements based upon several engineering disciplines. They include electronics, magnetics, feedback control systems, thermal, magnetic and stress finite-element-analysis, SPICE dynamic circuit and system simulation, rotational dynamics, aerodynamics, hydrodynamics, and materials science, Each discipline has standard terminology and illustration methods, to convey its structures and system combinations in the most concise and understandable way to persons versed in those disciplines. The descriptions and illustrations herein are intended to convey the most essential features of the present invention accurately, clearly, and concisely. Features set forth in prior art, with new improvements facilitated by the present invention, are herein briefly described, to explain differences and to provide clear comparisons. While dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com