Method and apparatus for in-situ monitoring of plasma etch and deposition processes using a pulsed broadband light source

a plasma etching and in-situ monitoring technology, applied in the field of semiconductor/solid-state device testing/measurement, instruments, vacuum evaporation coating, etc., can solve the problems of inconvenient in-situ monitoring of plasma etching and deposition processes, fluctuation of plasma emission can also confound models used to determine etching rate, and the method is not useful in several etching processes, etc., to reduce reducing the effect of plasma emission ratio ratio ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

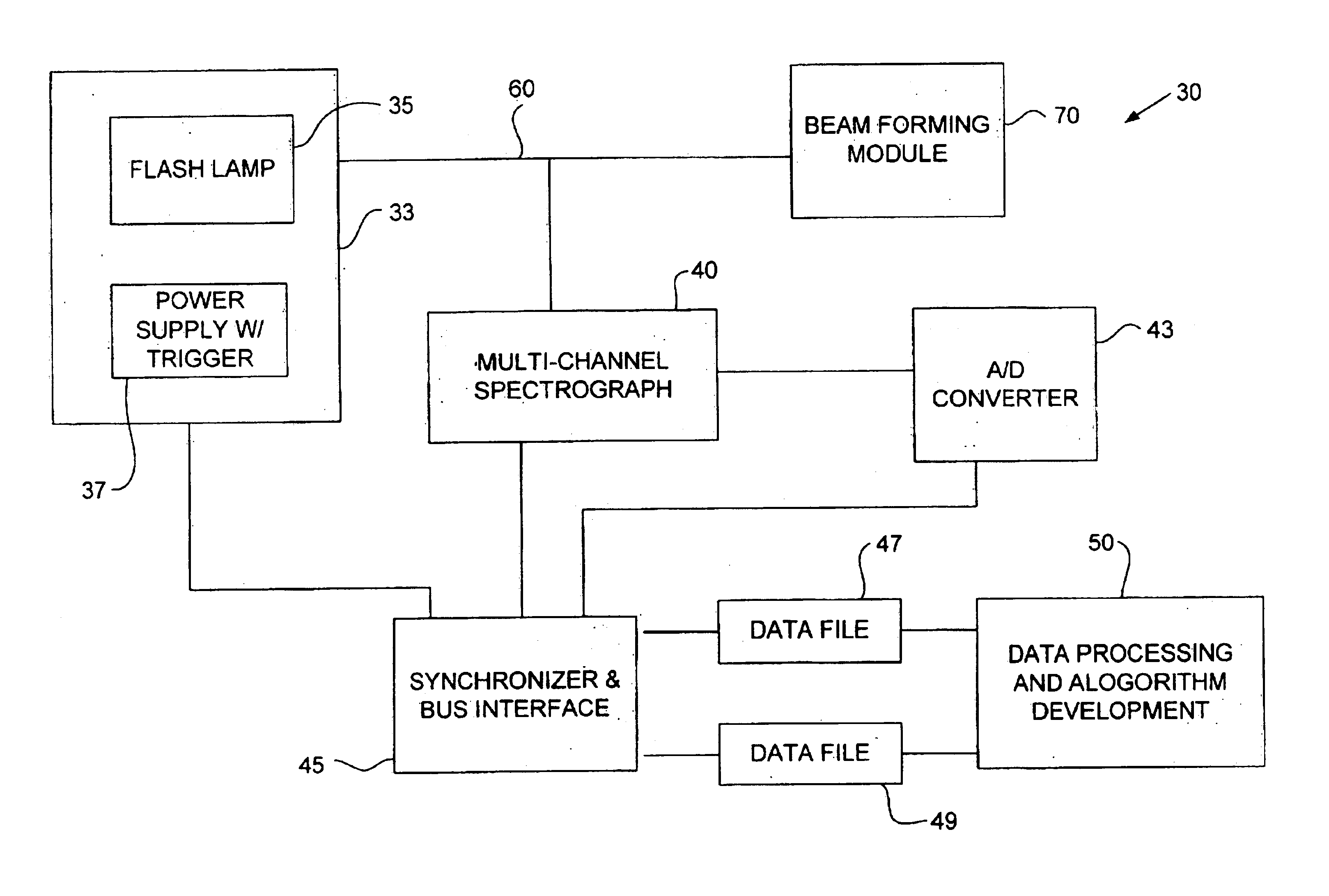

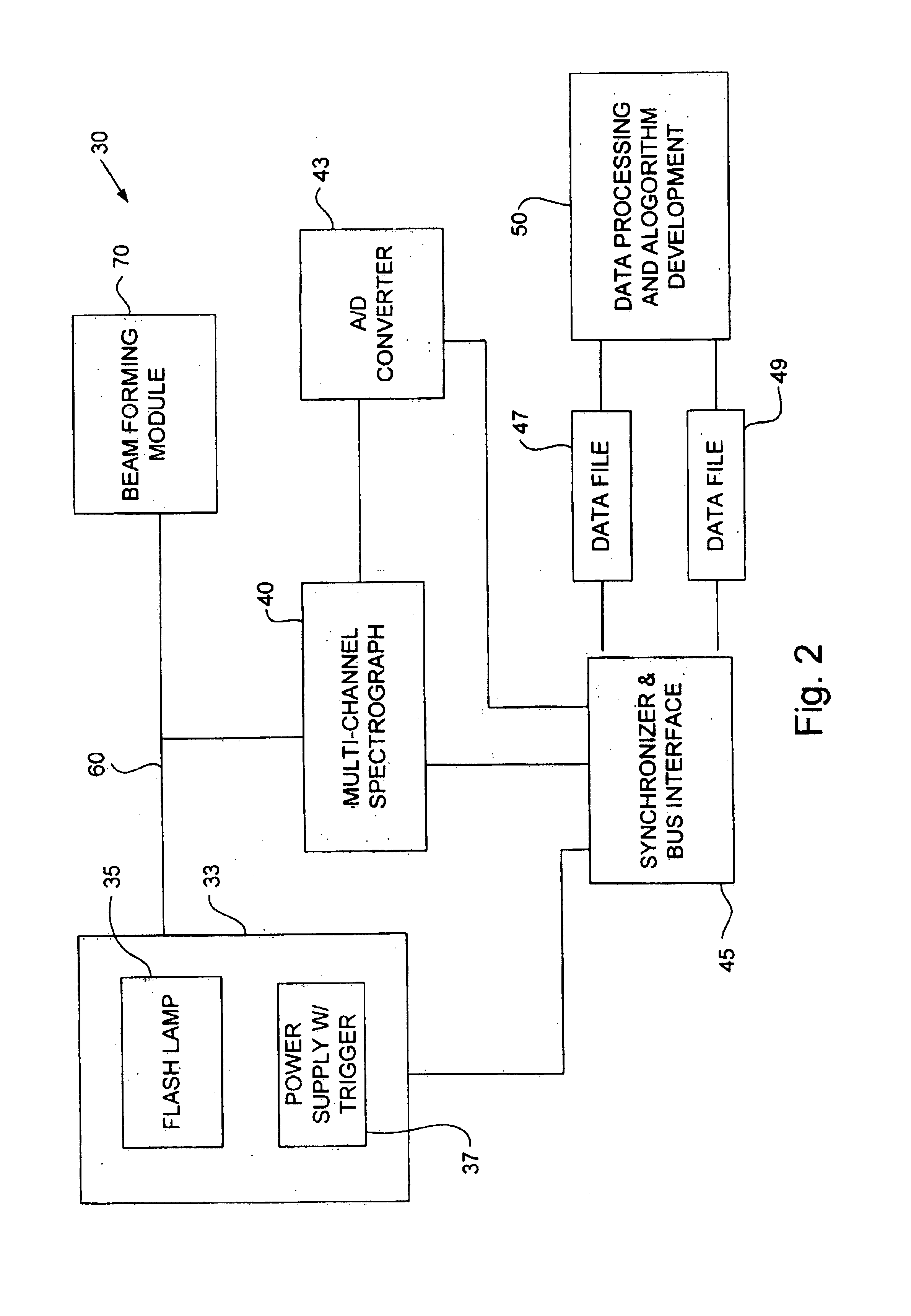

[0023]FIG. 2 shows the components of a system generally designated 30 using multiple wavelength illumination. The system 30 comprises an illumination module 33 comprising a flash lamp 35 and a power supply with trigger 37. The system 30 also comprises a multi-channel spectrograph 40, an analog-to-digital converter 43, a synchronizer and bus interface 45, a first and second data file 47 and 49 and a data processing and algorithm development block 50. An optical fiber 60 optically connects the flash lamp 35 and the spectrograph 40 to a beam forming module 70 disposed outside of a plasma chamber. This system 30 is used to calculate the thickness of a film on a wafer positioned within the plasma chamber, as described below.

[0024]The flash lamp 35 generates broadband light in the range of about 200 nm to 2 microns. The optical fiber 60 carries the broadband light from the flash lamp 35 to the beam forming module 70 disposed outside the plasma chamber. The beam forming module 70 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical radiation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com