Energy-saving quick fermentation agent and jean water-washing treatment technique

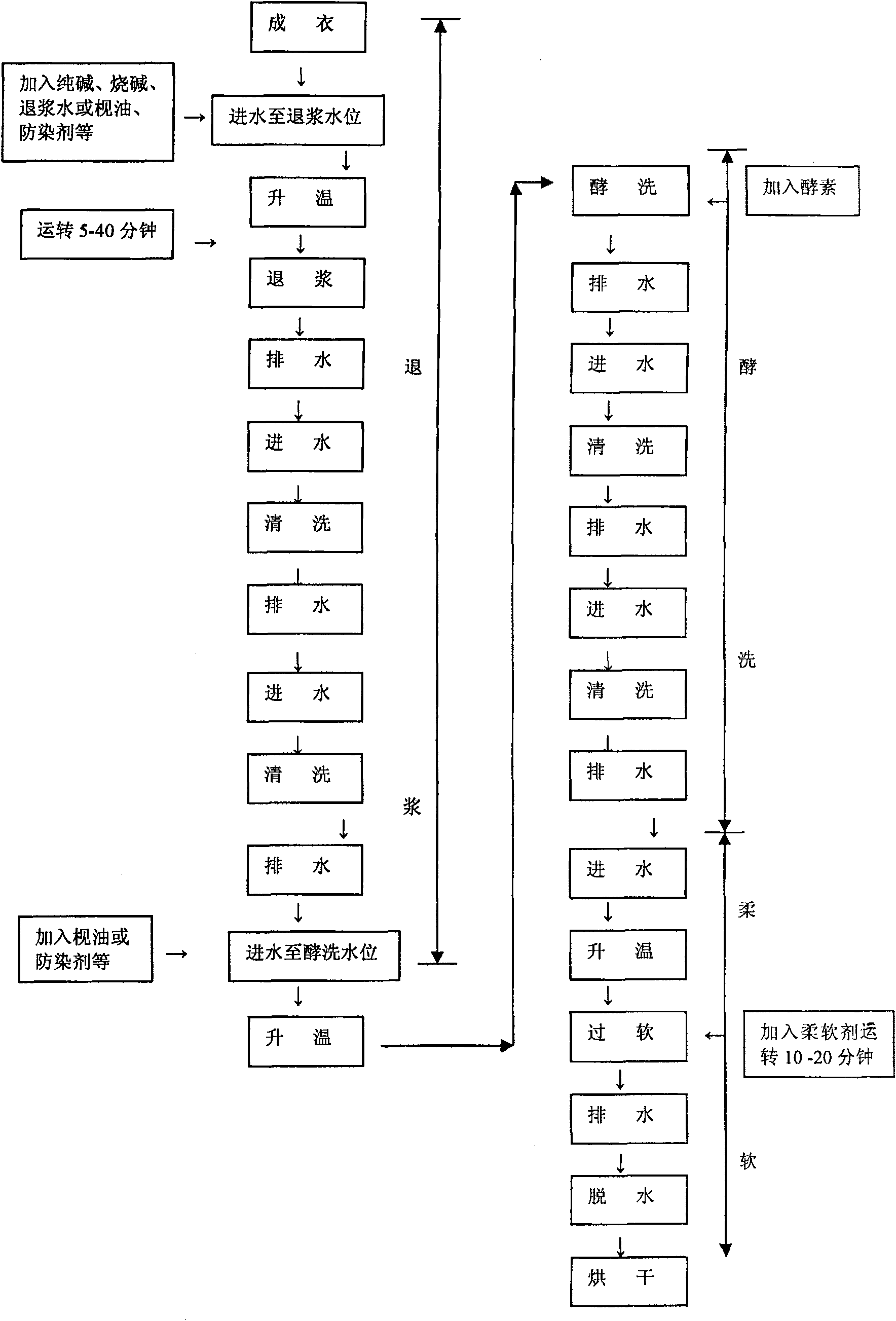

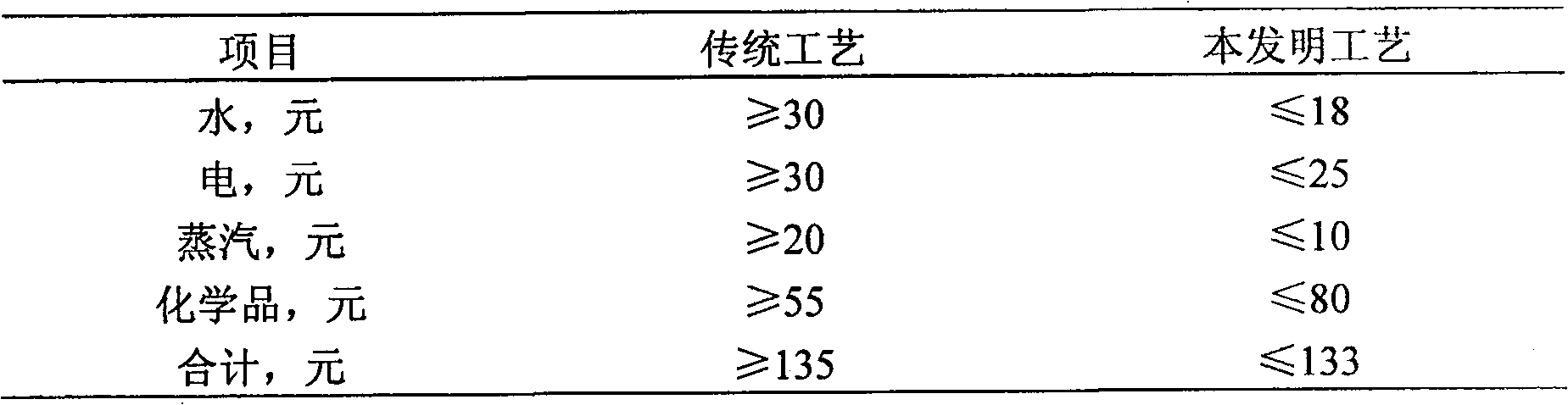

A technology of instant starter and buffer, which is applied in fiber treatment, biochemical fiber treatment, textile material treatment, etc. It can solve the problems of serious environmental pollution, long working time, and low production efficiency, and achieve simplified process flow and comprehensive cost reduction. Low, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The processed fabric of the present embodiment is 100% cotton light and thin denim clothing, which is easier to desizing, and the energy-saving instant starter used consists of: biological enzyme 20%, surfactant 30%, pH buffer (lemon acid, sodium citrate) 30%, softener (Dow Corning GP8000) 10%, filler (pure water, diatomaceous earth or silicon dioxide) 10%.

[0036] Wherein, the bio-enzyme consists of 72% cellulase, 8% amylase, 10% pectinase, 5% hemicellulase and 5% lipase according to weight percentage. According to the percentage by weight, the surfactant is composed of: 50% of fatty alcohol polyoxyethylene ether, 10% of polyether polyol, 30% of modified polyester and 10% of polyethylene glycol.

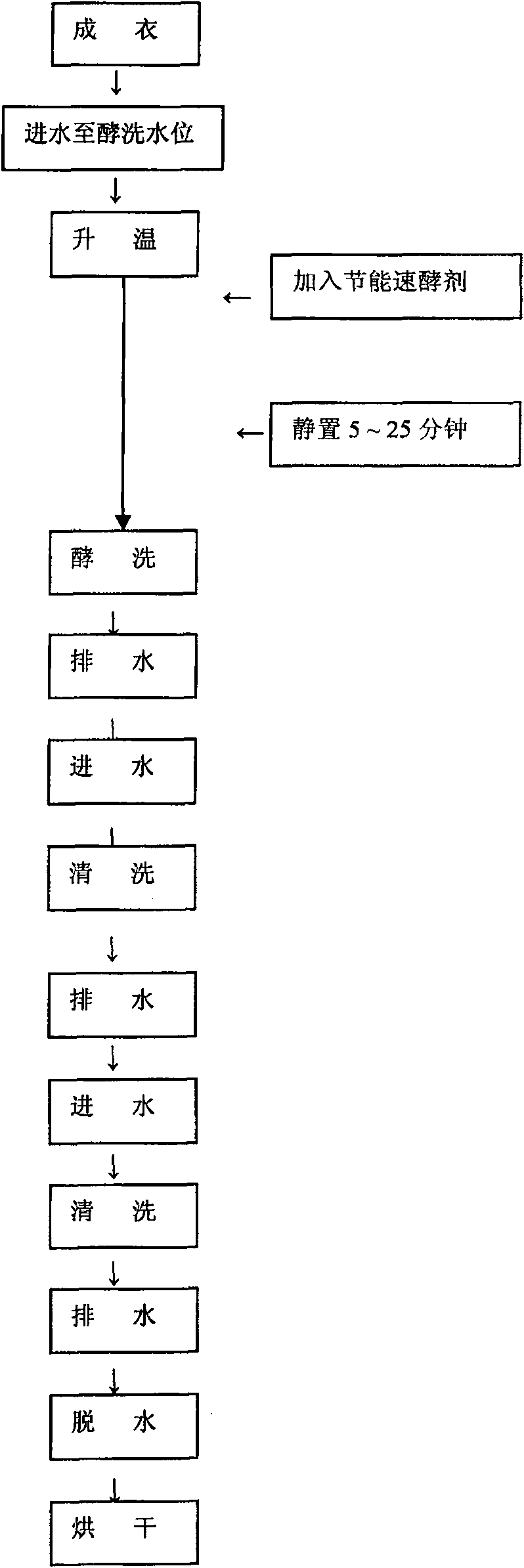

[0037] The processing equipment of the present embodiment is a 650-pound washing machine, and its steps of the processing technology are as follows (see figure 2 ):

[0038] 1) Add the finished garment to the washing machine;

[0039] 2) Control the water level at the ye...

Embodiment 2

[0046] The fabric processed in this embodiment is 100% cotton black mercerized denim clothing, which is more difficult to desizing, and the energy-saving instant starter used is composed of: biological enzyme 25%, surfactant 35%, pH value buffer ( Sodium dihydrogen phosphate, disodium hydrogen phosphate) 35%, softener (Dow Corning GP8000) 5%.

[0047] Wherein, the bio-enzyme consists of 63% cellulase, 15% amylase, 5% pectinase, 8% hemicellulase, 2% lipase, 2% protease and 5% laccase according to the weight percentage. According to the percentage by weight, the surfactant is composed of: 45% of fatty alcohol polyoxyethylene ether, 5% of polyether polyol, 35% of modified polyester, 8% of polyethylene glycol and 7% of polyvinylpyrrolidone.

[0048]The processing equipment of this embodiment is a 650-pound washing machine, and its processing technology is different from that of Embodiment 1 in that: the temperature controlled by steam heating in step 2) is 50°C; the consumption of...

Embodiment 3

[0050] The processed fabric of the present embodiment is elastic jeans, and the energy-saving quick-starter used is composed of: biological enzyme 22%, surfactant 28%, pH buffer (sodium dihydrogen phosphate, disodium hydrogen phosphate) 30%, softener (Dow Corning GP8000) 10%, filler (pure water, diatomaceous earth or silicon dioxide) 10%.

[0051] Wherein, the bio-enzyme consists of 65% cellulase, 25% amylase, 5% pectinase, 2% hemicellulase, 1% lipase and 2% laccase according to the weight percentage. According to the percentage by weight, the surface active agent is composed of 50% of fatty alcohol polyoxyethylene ether, 5% of polyether polyol, 30% of modified polyester, 5% of polyethylene glycol and 10% of polyvinylpyrrolidone.

[0052] The processing equipment of this embodiment is a 650-pound washing machine, and its processing technology is different from that of Embodiment 1 in that: the temperature controlled by steam heating in step 2) is 35° C.; the standing soaking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com