Preparation method of anatase rutile titania photocatalyst

A titanium dioxide, anatase type technology, applied in the field of synthesizing anatase type titanium dioxide powder, can solve problems such as unfavorable photocatalytic reaction, lengthy deposition time, reducing specific surface area, etc., and achieve low cost, low temperature and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: anatase type titanium dioxide (TiO 2 ) powder preparation

[0026] The preparation method of anatase type titanium dioxide powder of the present invention mainly comprises the following steps:

[0027] Prepare a suitable concentration of titanium-containing solution, preferably (NH 4 ) 2 TiF 6 Aqueous solution, in the present embodiment preferred concentration 0.4M (NH 4 ) 2 TiF 6 aqueous solution, the (NH 4 ) 2 TiF 6 Aqueous solution and one can be with (NH 4 ) 2 TiF 6 The aqueous solution is mixed with the reacting solution. In the present invention, since Ti ion is a transition element, its electron configuration can react with acid or alkali solution, so the said can react with (NH 4 ) 2 TiF 6 The solution that the aqueous solution reacts can be acidic solution or alkaline solution, and preferred acidic solution can be boric acid (H 3 BO 3 ), the preferred alkaline solution can be NaOH, NH 4 OH, or KOH. In a specific embodiment of ...

Embodiment 2

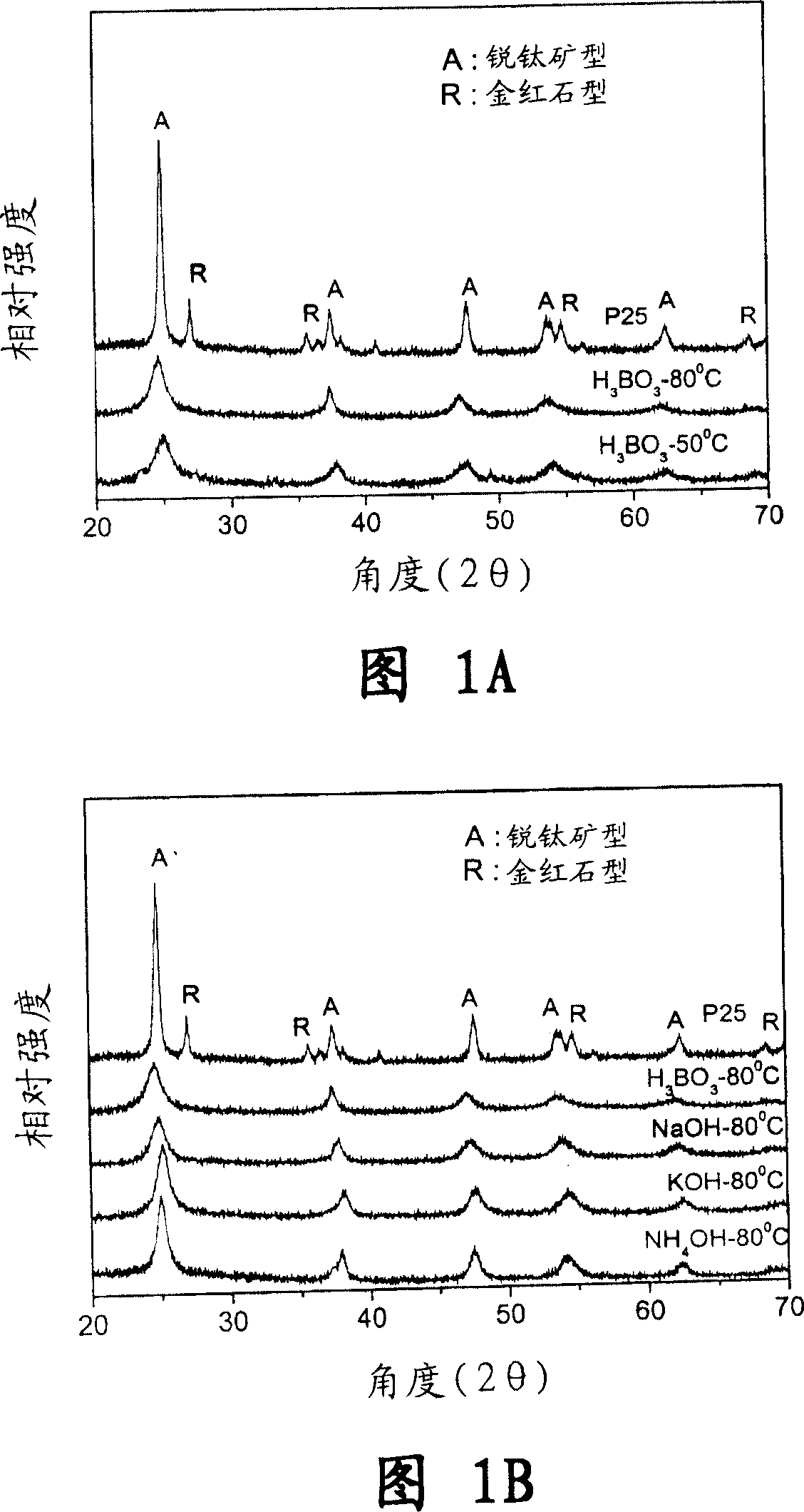

[0030] Embodiment two: the anatase type titanium dioxide (TiO2) obtained by different conditions 2 ) Characterization analysis of powder

[0031] As shown in Figure 1A and Figure 1B, the anatase titanium dioxide powder prepared by the present invention is analyzed by XRD spectrum, and it can be seen that there are obvious X at 25.5°, 38°, 47°, 54° and 62°. Light diffraction peaks, and commercially available AEROXIDE TiO 2 P25 is not the same, indicating that whether it is (NH 4 ) 2 TiF 6 with H 3 BO 3 The reaction is carried out under the reaction conditions of 50°C-100°C, or (NH 4 ) 2 TiF 6 With NaOH, NH 4 Three different alkaline solutions such as OH or KOH are reacted under the reaction conditions of 80°C-100°C, and the obtained TiO 2 The crystal form of the powder is a single anatase phase. Its characteristic X-ray diffraction peak is broad, indicating that the grain size of the sample is small.

[0032] As shown in the following table 1, the BET specific s...

Embodiment 3

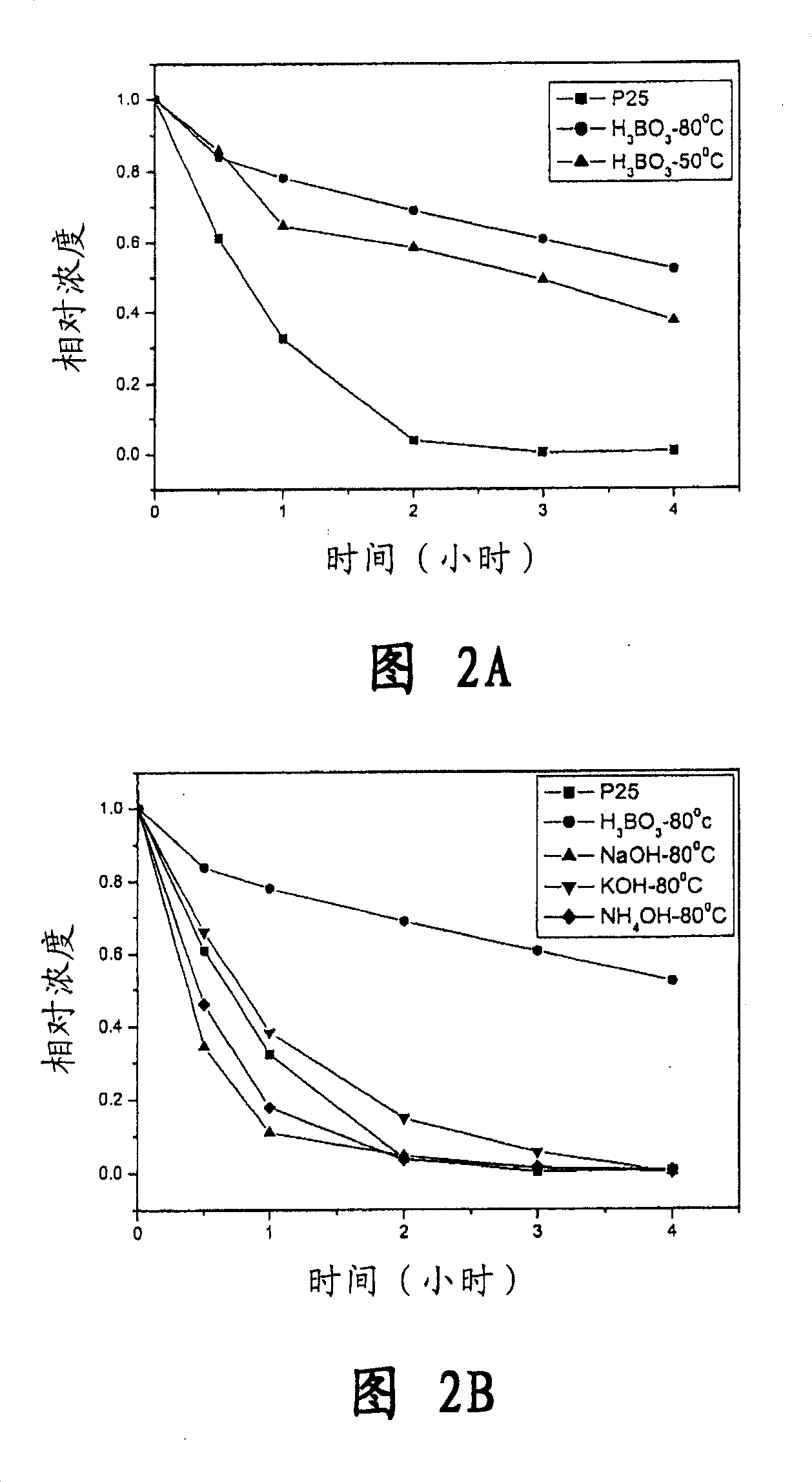

[0034] Example 3: Evaluation of Photocatalytic Performance

[0035] The photocatalytic experiment was carried out according to the steps listed below:

[0036] Prepare 100ml of 10ppm methyl orange aqueous solution with pH=3, and put it into a 125ml Erlenmeyer flask;

[0037] Weigh 0.1 gram of titanium dioxide powder and put it into the aforementioned Erlenmeyer flask;

[0038] The prepared solution was placed in a closed dark room and stirred for 12 hours, and then irradiated with ultraviolet light with a wavelength of 365nm to carry out photocatalytic reaction for 4 hours;

[0039] After the reaction, the catalyst titanium dioxide powder is recovered by centrifugation and dried.

[0040] Taking the degradation of methyl orange aqueous solution as the target reaction to detect the photocatalytic performance of titanium dioxide powder, the higher the degradation rate of methyl orange aqueous solution in a shorter time, the better the photocatalytic performance. The concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com