Method for extracting vanadium pentoxide from Stone-like coal vanadium ore and special device for the same

An extraction and mineral powder technology, applied in the field of extracting vanadium pentoxide, can solve the problems of low extraction rate, low yield and low conversion rate of stone coal vanadium ore, so as to accelerate the oxidative conversion speed and conversion rate, and improve the oxidation rate. Conversion rate, the effect of improving acid-dissolving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Extraction and preparation of vanadium pentoxide

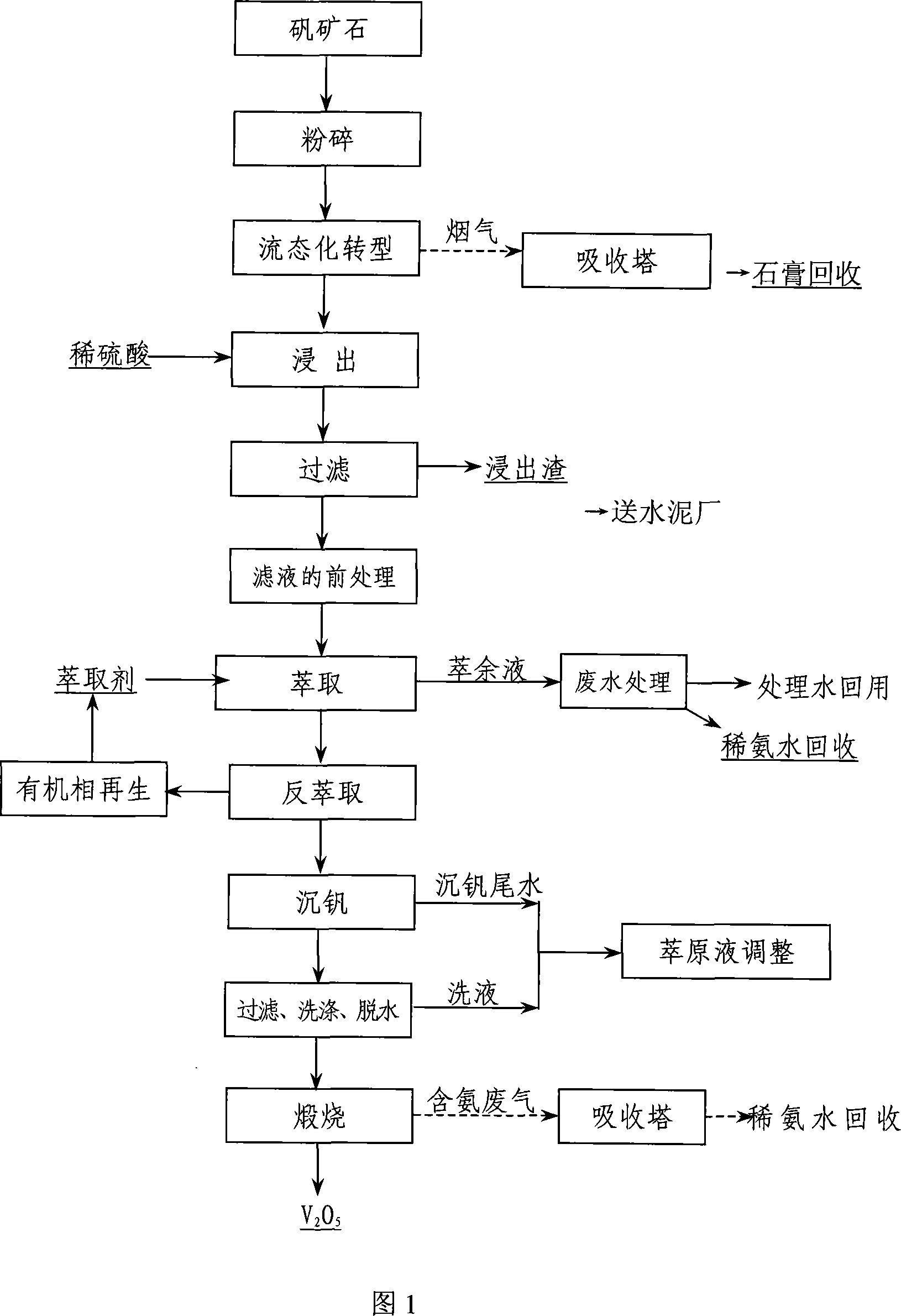

[0046] The extraction and preparation of high-purity vanadium pentoxide by adopting a method for extracting vanadium by fluidized bed oxidation transition acid leaching comprises the following steps:

[0047] 1. Stone coal mine 6940kg (of which the vanadium content is 0.545%, equivalent to V 2 o 5 The average content is 0.97%). After column milling, sieve the mineral powder with a particle size of -60 mesh, wherein the mineral powder with a particle size of -200 mesh is not less than 30%;

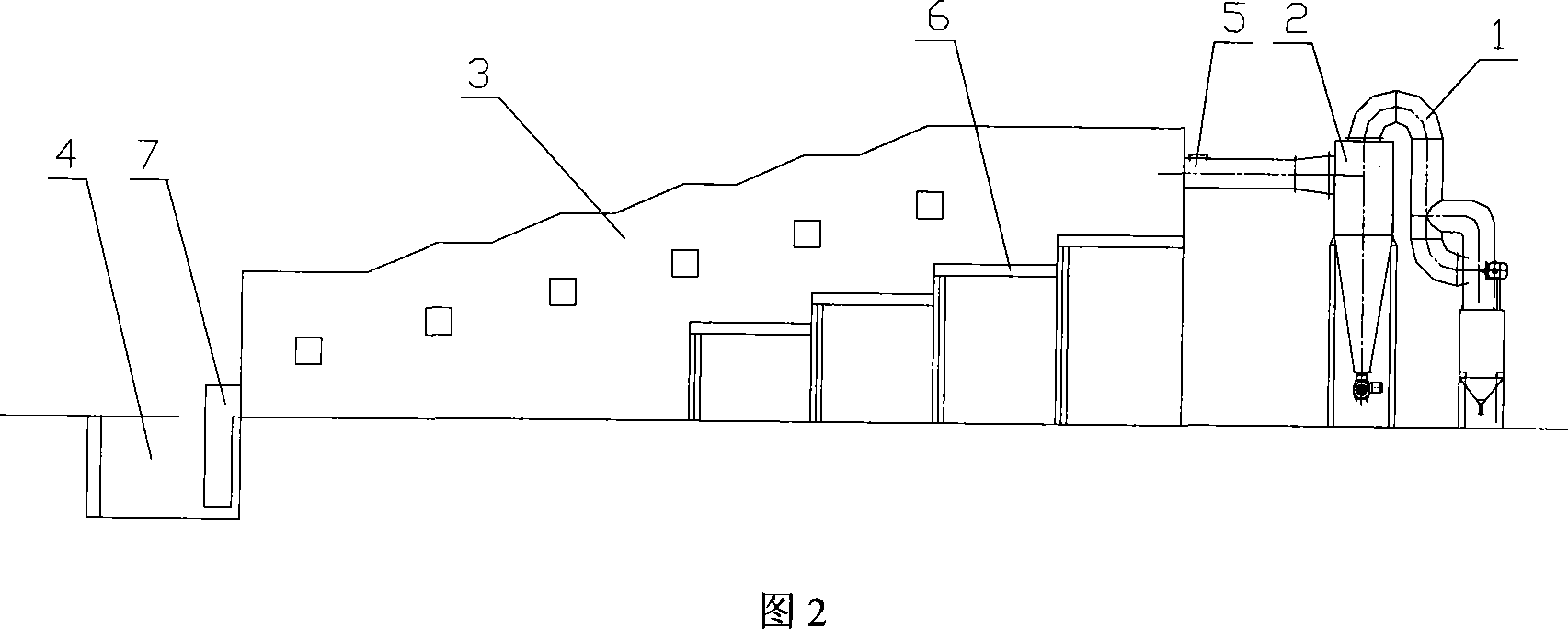

[0048] 2. After the ore powder is introduced into the fluidized bed from the feed port, it enters the high-temperature oxidation zone at 900°C after preheating at 600°C. The high-temperature oxidation zone is equipped with multiple steps. After cooling in the cooling zone, it enters the receiving bin from the discharge port to obtain slag powder after oxidation transformation treatment. The leaching rate is 78%, which is ...

Embodiment 2

[0066] Example 2 Fluidized bed conversion acid leaching extraction method for extracting vanadium

[0067] Stone coal vanadium ore 6940kg (0.46% vanadium content is equivalent to V 2 o 5 Average content is 0.82%), and preparation method is with embodiment 1.

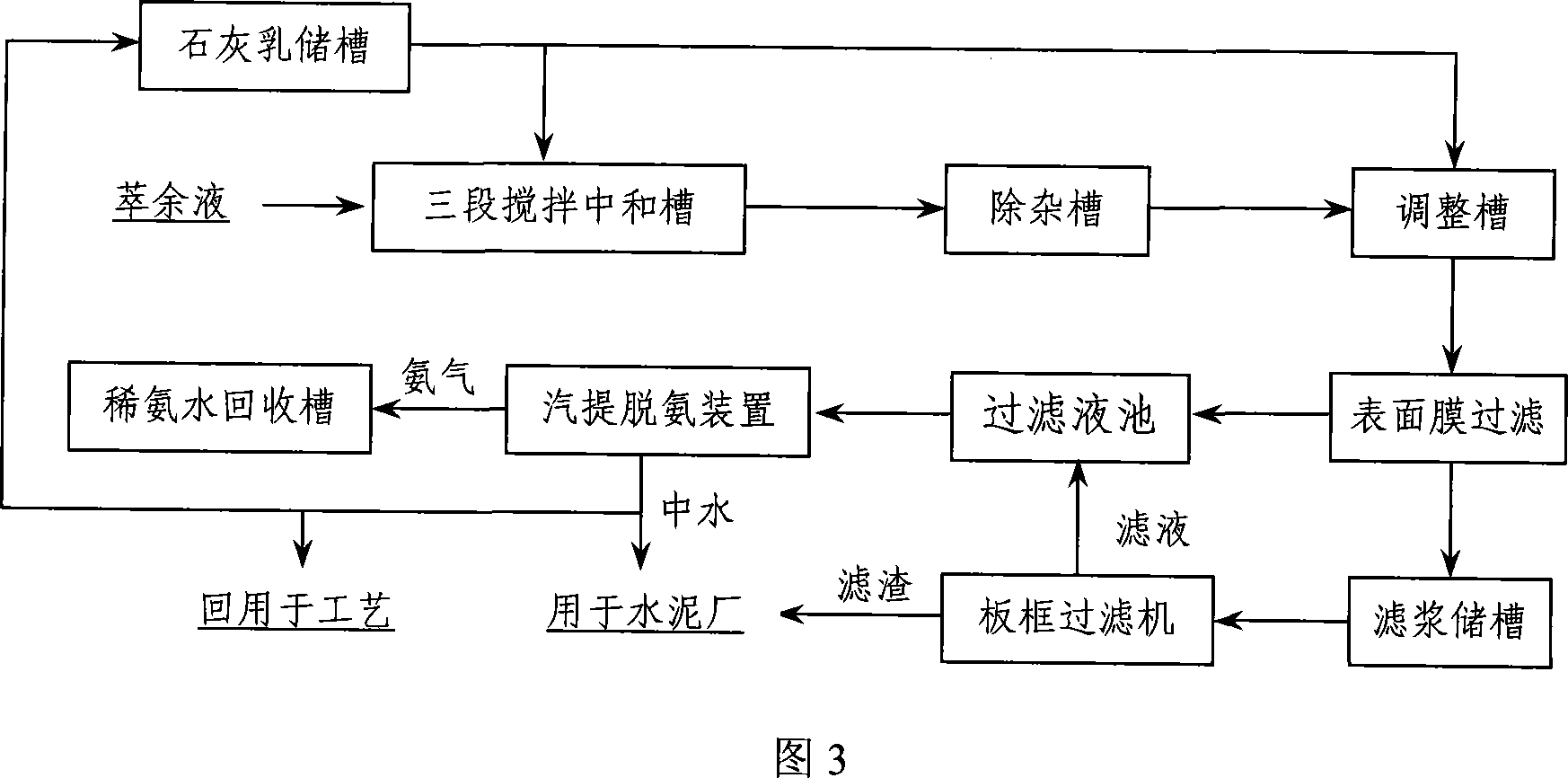

[0068] See Table 1 for the proportions of vanadium in different valence states in stone coal mines before and after fluidized bed oxidation transformation treatment. The recovery rate is 69%, which is 61% higher than the leaching rate without fluidized bed oxidation treatment. The total direct recovery rate is 60.16%, the total recovery rate is 63.78%, and the purity of the obtained vanadium pentoxide is 99.35%. See Table 2 for other test results.

Embodiment 3

[0069] Embodiment 3 Preparation of vanadium pentoxide

[0070] Stone coal vanadium ore 6940kg (wherein vanadium content 0.48%), preparation method is the same as embodiment 1, the test result of gained vanadium pentoxide product is referring to table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com