Ceramic coating member for semiconductor processing apparatus

A technology for processing devices and covering components, which is applied in semiconductor/solid-state device manufacturing, superimposed layer plating, electrical components, etc., can solve problems such as corrosive environments and instrument damage, and achieve improved plasma output, increased productivity, and improved The effect of etch effect and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0076] In this experimental example, the state of sputtered film formation of Group IIIB element oxides, and the state of the layer formed when electron beam irradiation and laser beam irradiation were performed on the obtained film were investigated. In addition, Sc 2 o 3 , Y 2 o 3 , La 2 o 3 , CeO 2 、Eu 2 o 3 、Dy 2 o 3 and Yb 2 o 3 Seven kinds of oxide powders (average particle size: 10-50 μm). Then, these powders are directly sprayed with a thickness of 100 μm by atmospheric plasma spraying (APS) and reduced pressure plasma spraying (LPPS) on one side of an aluminum test piece (size: width 50mm x length 60mm x thickness 8mm). coating. Then, the surfaces of these films were subjected to electron beam irradiation treatment and laser beam irradiation treatment. Table 1 summarizes the results of this experiment.

[0077] In addition, the actual results of the spraying of lanthanide metal oxides with atomic numbers from 57 to 71 have not been reported so far. Ther...

experiment example 2

[0085] In this experimental example, from the test piece after the high-energy irradiation treatment made in the above-mentioned test 1, for Y 2 o 3 For the sprayed coating, observe the section of the sprayed coating before and after the electron beam irradiation treatment with an optical microscope, and observe the changes in the microstructure of the film produced by the high-energy irradiation treatment.

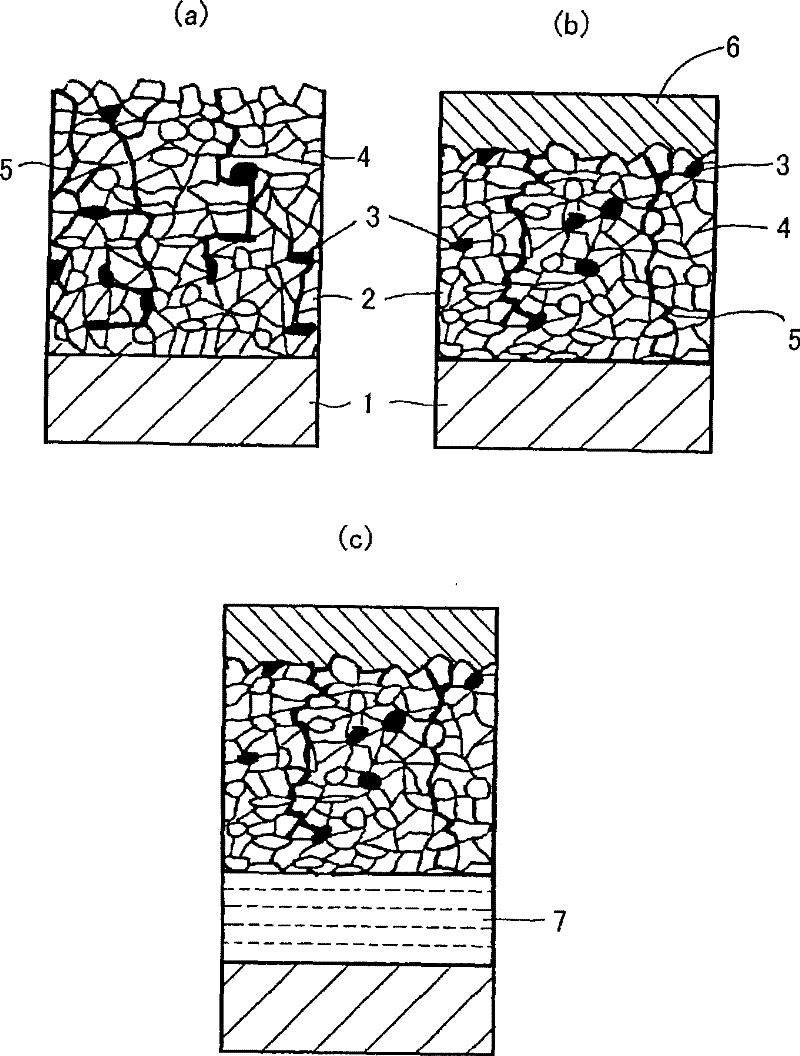

[0086] figure 1 is schematically denoting Y 2 o 3 Changes in the microstructure near the surface of a thermally sprayed film (porous film), a film subjected to electron beam irradiation treatment, and a composite film with an undercoat layer. exist figure 1 In the non-irradiation-treated test piece shown in (a), it can be seen that the sprayed particles constituting the film exist independently, and the surface roughness is large. on the other hand, figure 1 (b) shows that a new layer having a different microstructure was formed on the above-mentioned sprayed coatin...

experiment example 3

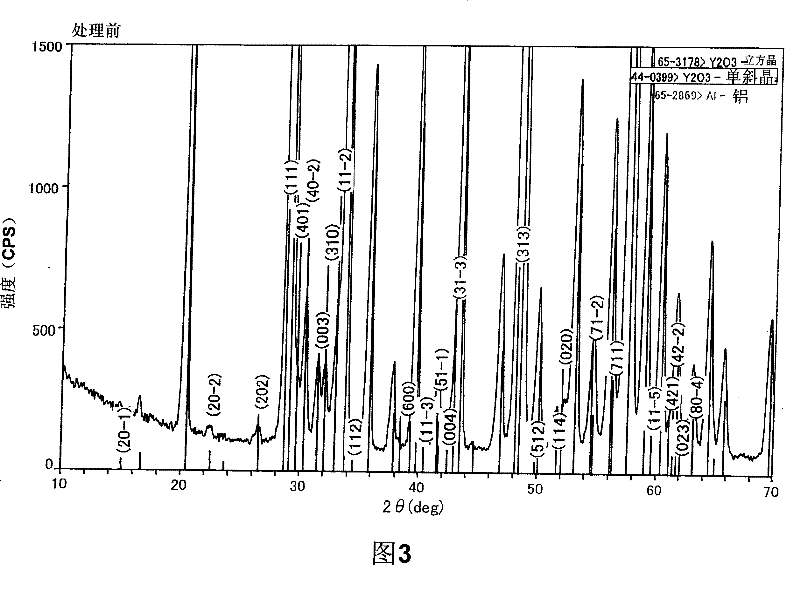

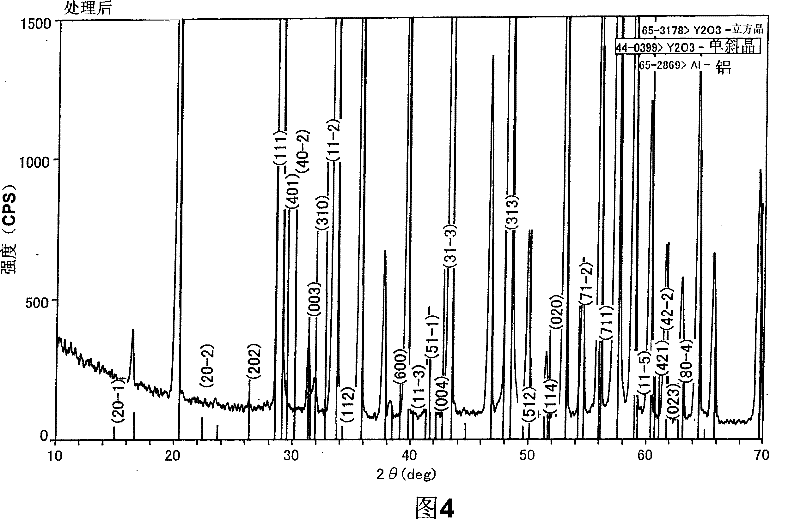

[0089] This experimental example is determined by XRD figure 1 (a) Y 2 o 3 The porous layer of the sprayed film, and the porous layer produced by electron beam irradiation under the following conditions figure 1 The secondary recrystallized layer shown in (b) was studied for the crystal structure of each layer. figure 2 To show this result, an XRD pattern before electron beam irradiation treatment is shown. and, image 3 is an X-ray diffraction pattern on the vertical axis before the enlargement process. Figure 4 It is the X-ray diffraction pattern of the vertical axis after enlargement processing. Depend on image 3 It was found that in the sample before treatment, a peak indicating monoclinic crystals was observed particularly in the range of 30 to 35°, and it was found that cubic crystals and monoclinic crystals were in a mixed state. In contrast, as Figure 4 Shown, means Y 2 o 3 The peaks of the particles become sharper, the peaks of monoclinic crystals attenu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com