Alkaline earth halogen silicate phosphor powder and preparation method thereof

A technology of halosilicate and phosphor, which is applied in the field of alkaline earth halosilicate phosphor and its preparation, can solve the problems of poor optical performance consistency of white light LED devices, increase the powder mixing process, etc., and achieve easy operation and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

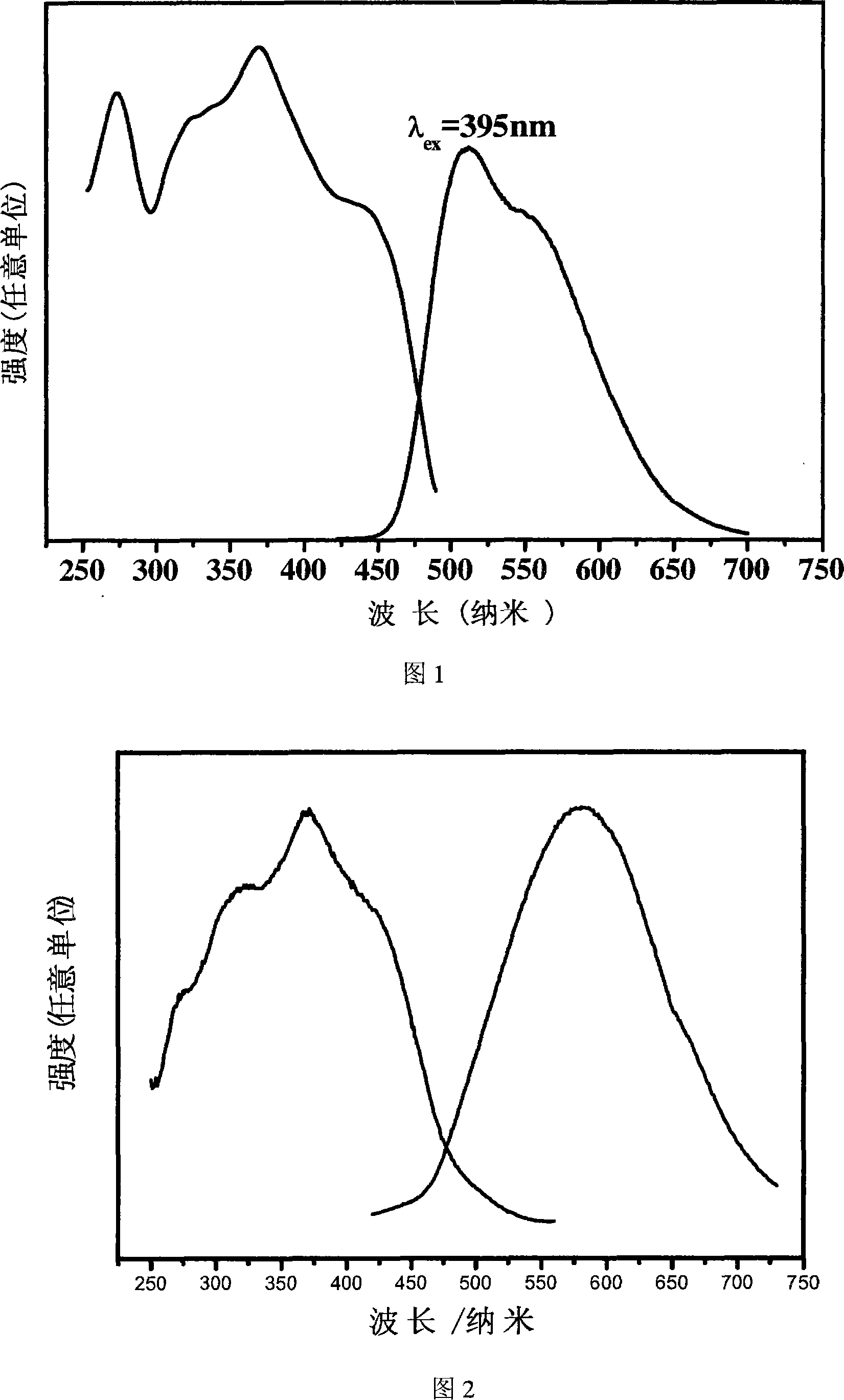

[0023] Embodiment 1: 2 (Ca 0.51 Sr 0.4 )O·0.8Ca(F 0.07 Cl 0.93 ) 2 ·SiO2 2 : Preparation of 0.03Eu·0.15Mn Phosphor Powder

[0024] Weigh calcium carbonate (CaCO 3 ) 2.0418g, silicon dioxide (SiO 2 ) 1.2017g, europium trioxide (Eu 2 o 3 ) 0.1056g, anhydrous calcium chloride (CaCl 2 ) 1.6514g, manganese carbonate (MnCO 3 ) 0.3448g, strontium oxalate (Sr(CH 3 COO) 2 0.5H 2 O) 3.4355g, calcium fluoride (CaF 2 ) 0.0874g, flux lithium carbonate (Li 2 CO 3 ) 0.7981g, after grinding and mixing the above raw materials in an agate mortar, put them into a corundum crucible, first burn them at 600°C for 2 hours, then take them out and grind them, then put them into a corundum crucible, and pass through the corundum crucible before heating Inject high-purity nitrogen to drive out the air in the quartz tube, and then burn it at 800°C for 6 hours under a carbon monoxide atmosphere. After cooling, grind it evenly, then crush it and sieve it, and wash it with water and ethanol ...

Embodiment 2

[0025] Embodiment 2: 2 (Ca 0.8945 Sr 0.1 )O·CaCl 2 ·SiO2 2 : Preparation of 0.01Eu·0.001Mn Phosphor Powder

[0026] Weigh calcium carbonate (CaCO 3 ) 3.5811g, silicon dioxide (SiO 2 ) 1.2017g, europium trioxide (Eu 2 o 3 ) 0.0352g, anhydrous calcium chloride (CaCl 2 ) 2.2197g, manganese carbonate (MnCO 3 ) 0.0023g, strontium oxalate (Sr(CH 3 COO) 2 0.5H 2 (2) 0.8589g, fluxing agent ammonium chloride 0.3160g, after the above-mentioned raw materials are ground and mixed in the agate mortar, put into the corundum crucible, first burn in advance at 600 ℃ in air for 2 hours, then after grinding, repack Put it into a corundum crucible. Before heating, inject high-purity nitrogen to drive out the air in the quartz tube, and then burn it in an ammonia atmosphere at 800°C for 3 hours. Wash and finally get the sample. The sample is excited under 400nm ultraviolet light or 460nm blue light, which mainly emits yellow-green light. The room temperature excitation and emission ...

Embodiment 3

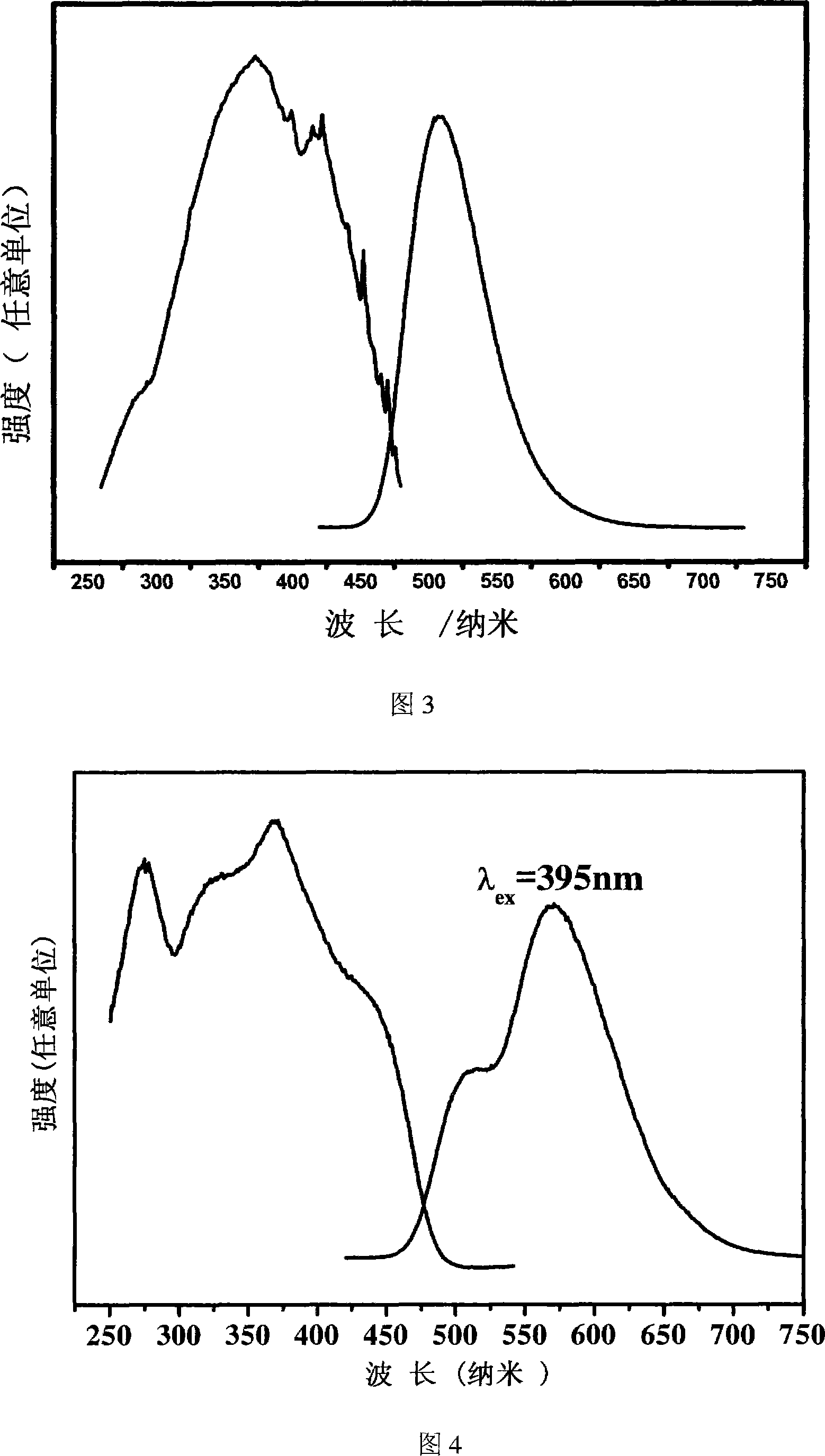

[0027] Embodiment 3: 2 (Ca 0.625 Sr 0.3 )O·1.2Ca(F 0.05 Cl 0.95 ) 2 ·SiO2 2 : Preparation of 0.05Eu·0.1Mn Phosphor Powder

[0028] Weigh calcium carbonate (CaCO 3 ) 2 .5022g, silicon dioxide (SiO 2 ) 1.2017g, europium trioxide (Eu 2 o 3 ) 0.1760g, anhydrous calcium chloride (CaCl 2 ) 2.5304g, manganese carbonate (MnCO 3 )0.2299g, strontium oxalate (Sr(CH 3 COO) 2 0.5H 2 O) 2.5766g, calcium fluoride (CaF 2) 0.0937g, flux ammonium fluoride 0.0047g, after grinding and mixing the above raw materials in an agate mortar, put them into a corundum crucible, pre-fire in the air at 500°C for 4 hours, then grind them, and then put them into In the corundum crucible, before heating, inject high-purity nitrogen gas to drive out the air in the quartz tube, and then burn it in a carbon monoxide atmosphere at 700°C for 7 hours. After cooling, grind it evenly, then crush it and sieve it, and wash it with water and ethanol respectively. Finally got the sample. The sample is exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com