A structure-optimized white light organic EL part

An electroluminescent device, an organic technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of a wide variety of organic materials, complicated preparation processes, etc., reduce the preparation cost and production process, simplify the preparation process, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

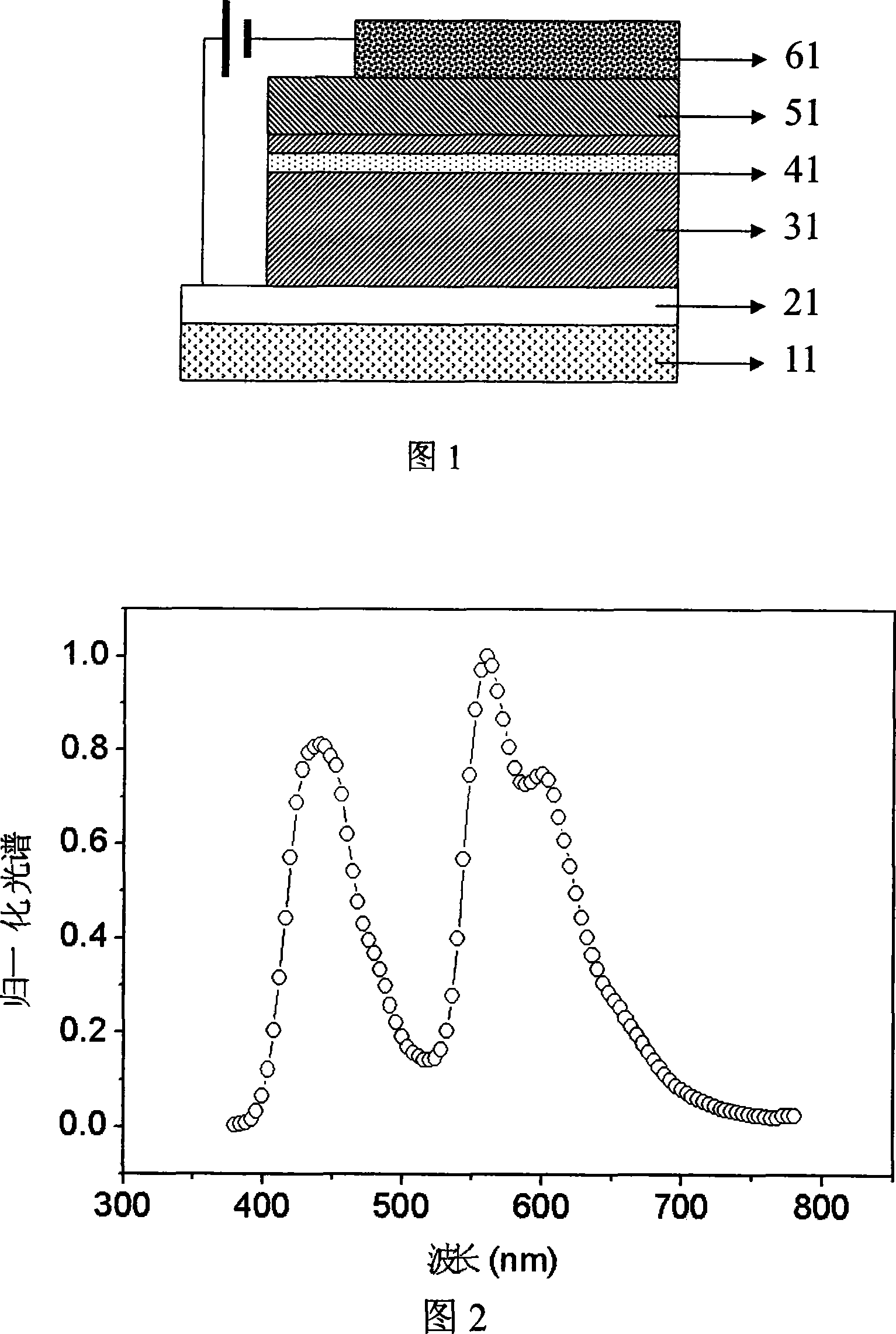

[0047] The device structure of this embodiment is shown in FIG. 1 , the device substrate 11 is glass, and the anode layer 21 used is an indium tin oxide (ITO) film. Obtain the required anode layer 21 pattern on the ITO film by photolithography, then ultrasonically clean it with lye, acetone, ethanol, and deionized water, and dry it with high-purity nitrogen before use; put the cleaned ITO substrate into the pretreatment chamber body, in a vacuum higher than 10 -6 After Torr, an appropriate amount of nitrogen and oxygen is introduced for plasma treatment to improve the work function of the ITO film. After the pretreatment is completed, it is directly transferred to the organic thin film evaporation chamber; in a high vacuum environment, start to evaporate the hole transport layer 31NPB with a thickness of 40nm; then close the baffle of the substrate and open the doping material (t-bt) 2 The evaporation power supply of Ir (acac), after reaching the required rate, open the baffl...

Embodiment 2

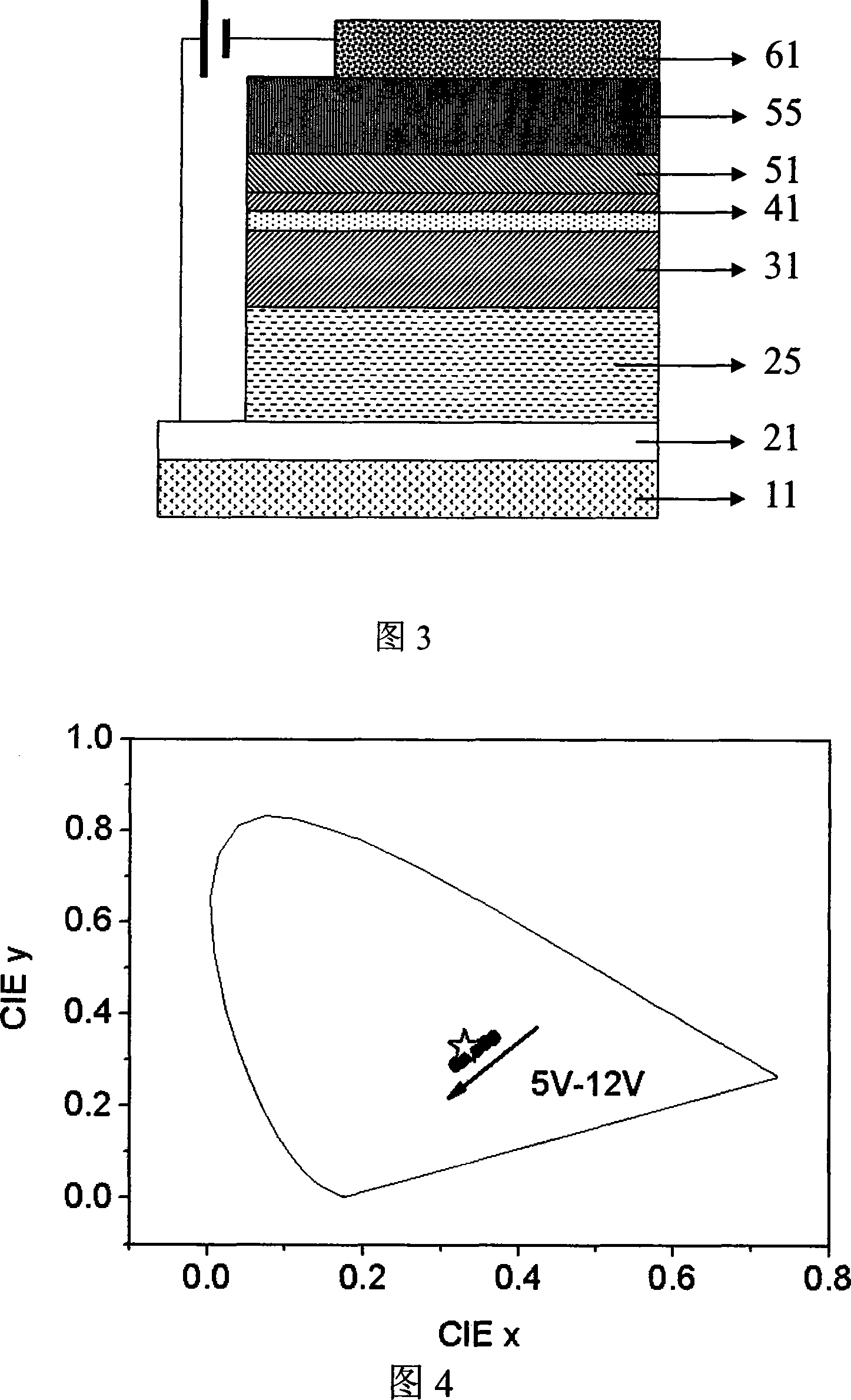

[0050] On the basis of Example 1, we increase the hole injection layer 25 between the anode layer 21 and the hole transport layer 31, and the yellow light doping material (t-bt) 2 Ir(acac) is replaced by Rubrene, and an electron injection layer 55 is added between the hole blocking layer 51 and the cathode 61 . The device structure is shown in Figure 3, and the materials and layer thicknesses used are: ITO / CuPc (30nm) / NPB (30nm) / NPB: Rubrene (0.4%, 30nm) / NPB (1nm) / BCP (10nm) / Alq (20nm) / LiF (1nm): Al (100nm). The preparation method of the device was the same as that in Example 1, and the device was tested with a Keithley 2400 voltage-current source combined with a PR650 spectrometer.

[0051] The device has a color coordinate of (0.357, 0.337) and a brightness of 630cd / m at 6V 2 , the color coordinates at 8V voltage are (0.344, 0.329), and the brightness is 4840cd / m 2, the color coordinates at 10V voltage are (0.332, 0.310), and the brightness is 9670cd / m 2 . The color coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminescence spectrum | aaaaa | aaaaa |

| Luminescence spectrum | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com