Method for producing high-pure ultra-thin micro-powder magnesium hydroxide by extracting sea water

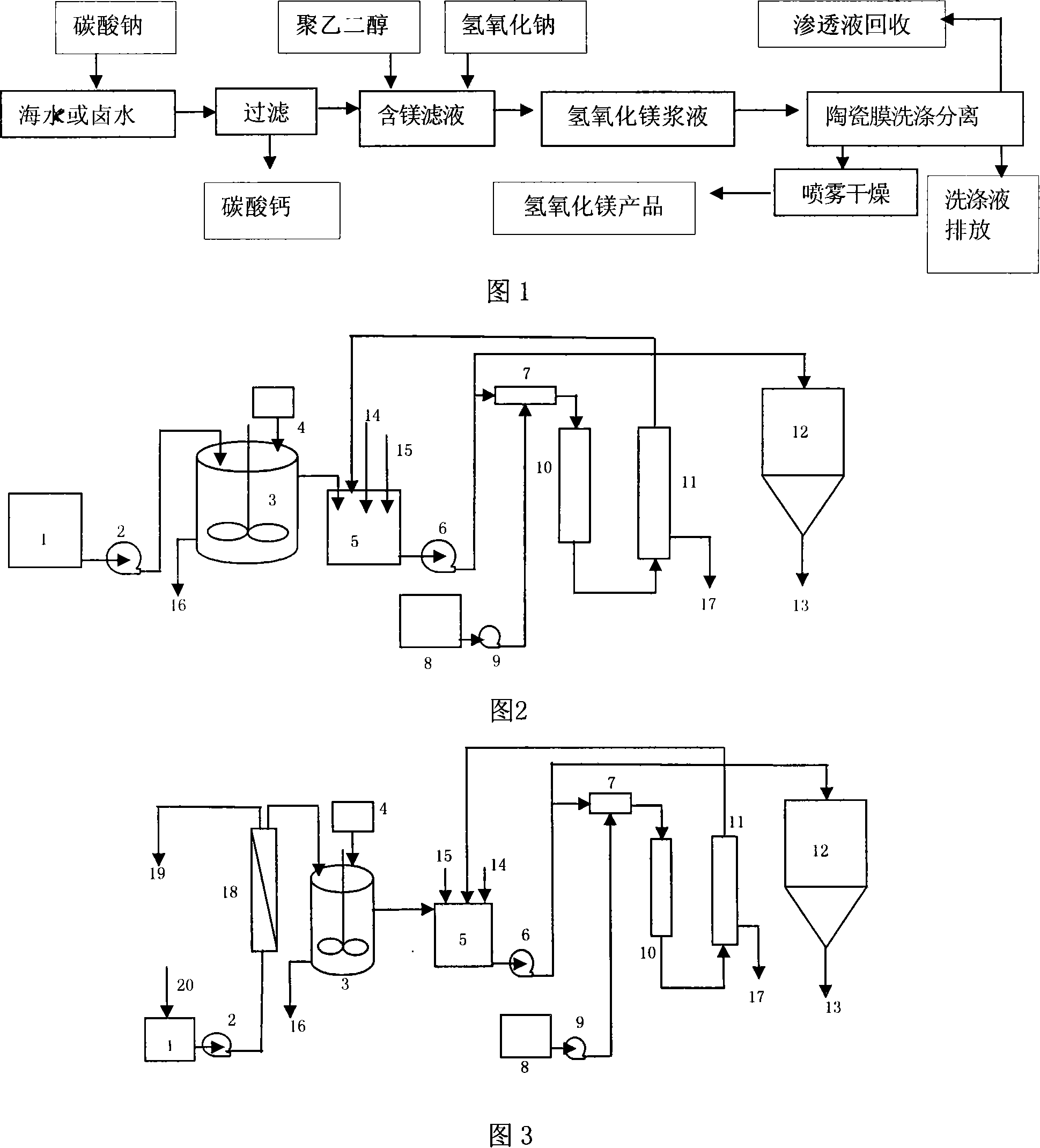

A technology of magnesium hydroxide and a production method, applied in directions such as magnesium hydroxide, can solve the problems of uncontrollable agglomeration of magnesium hydroxide particles, agglomeration of magnesium hydroxide particles, low yield and the like, achieves simple and easy operation for washing, and reduces land occupation. Area, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Take 160L of seawater after treatment with a 0.1 μm hollow fiber ultrafiltration membrane, and analyze the concentration of calcium and magnesium ions according to 1.4:1Na 2 CO 3 / Ca 2+ 1mol / L sodium carbonate solution was added, reacted for 2h at a stirring speed of 60r / min, stood still for 24h, pH=11, and poured the supernatant into a magnesium raw material tank. Add polyethylene glycol 1000, a dispersing agent with a theoretical magnesium hydroxide production rate of 2% in the magnesium raw material tank, and stir and mix evenly. The 2mol / L sodium hydroxide solution is mixed, fully reacted by the static mixer, and directly enters the 50nm ceramic ultrafiltration membrane unit. When concentrated to a solid content of 15% by a ceramic ultrafiltration membrane, use a centrifugal pump to pump into the deionized water concentrate, and repeat concentration and washing until the solid content is 15%. 3 Solution test without Cl - If it is detected or the conduc...

Embodiment 2

[0034]Example 2 Take 300L of seawater treated by a 0.2 μm hollow fiber microfiltration membrane, inject it into a nanofiltration membrane system through a high-pressure pump, and concentrate it to 1 / 3 of the volume of the raw material liquid, and put the concentrated liquid into a nanofiltration concentrated liquid tank. Analyze the concentration of calcium ions in the concentrate, according to 1.38:1Na 2 CO 3 / Ca 2+ The molar ratio, add 1mol / L sodium carbonate solution, react 3h under the condition of stirring speed 80r / min, stand still for 24h, supernatant is poured into the magnesium hydroxide raw material bucket. Add polyethylene glycol 1000, a dispersing agent with a theoretical magnesium hydroxide production rate of 2% in the magnesium raw material tank, and stir and mix evenly. The 1.8mol / L sodium hydroxide solution is mixed, fully reacted through the static mixer, and directly enters the 50nm ceramic ultrafiltration membrane unit. After being concentrated to a solid...

Embodiment 3

[0035] Example 3 Take 160L of concentrated seawater produced by the reverse osmosis membrane. After analyzing the concentration of calcium and magnesium ions, 2 CO 3 / Ca 2+ Add 1.5mol / L sodium carbonate solution, react for 30min under the condition of stirring speed of 100r / min, change the stirring speed of 40r / min for 4h, stand still for 24h, after centrifugal separation and concentration, put the filtrate into magnesium hydroxide raw material in the barrel. Add polyethylene glycol 1000, a dispersing agent with a theoretical magnesium hydroxide production rate of 2% in the magnesium raw material tank, and stir and mix evenly. The 1.5mol / L sodium hydroxide solution is mixed, fully reacted by the static mixer, and directly enters the 50nm ceramic ultrafiltration membrane unit. When concentrated by ceramic ultrafiltration membrane to a solid content of 20%, use a centrifugal pump to inject deionized water into the concentrated solution, and repeatedly concentrate and wash unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com