Polyalcohol integral separation medium and preparation process thereof

A separation medium and polymer technology, applied in ion exchange column/bed methods, chemical instruments and methods, ion exchange, etc., can solve the problems of low separation column efficiency and uneven distribution of surface functional groups, and achieve low column pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, preparation of monolithic column and weak cation exchange modification

[0021] Mix 1.2 mL glycidyl methacrylate (GMA), 0.8 mL ethylene glycol methacrylate (EDMA), 3 mL cyclohexanol, 0.4 mL dodecanol, 0.045 g azobisisobutyronitrile (AIBN) The solution was ultrasonically dissolved into a transparent homogeneous solution, and nitrogen gas was passed for 15 minutes. Then put the mixed solution into a dry stainless steel empty column tube, seal it and place it in a water bath at 55°C for 24 hours of reaction, then take it out and wash out the porogen and unreacted monomer with tetrahydrofuran.

[0022] A solution of ethylenediamine / tetrahydrofuran (1:1 by volume) was circulated through the chromatographic column at a flow rate of 0.1 mL / min at a constant temperature of 80° C. for 24 h. After the reaction is complete, wash the medium with dioxane / 20% sodium hydroxide (3:2, v / v), dioxane / water (3:2, v / v), methanol in sequence, and finally wash the medium with exce...

Embodiment 2

[0025] Example 2: Preparation of monolithic column and weak anion exchange modification

[0026] Dissolve 1.1mL of chloromethylstyrene and 0.6mL of divinylbenzene in a mixture of 3.5mL of cyclohexanol and 0.5mL of dodecanol, then add 0.045g of AIBN, ultrasonically dissolve into a homogeneous solution, and pass nitrogen gas for 15 minutes. Then put the mixed solution into a dry stainless steel empty column tube, seal it and place it in a 65°C water bath for 24 hours of reaction, then take it out and flush out the porogen and unreacted monomer with tetrahydrofuran.

[0027] A solution of ethylenediamine / tetrahydrofuran (1:1 by volume) was circulated through the chromatographic column at a flow rate of 0.1 mL / min at a constant temperature of 85° C. for 24 h. After the reaction is complete, wash the chromatographic column with excess methanol and water successively to obtain a weak anion exchange monolithic column.

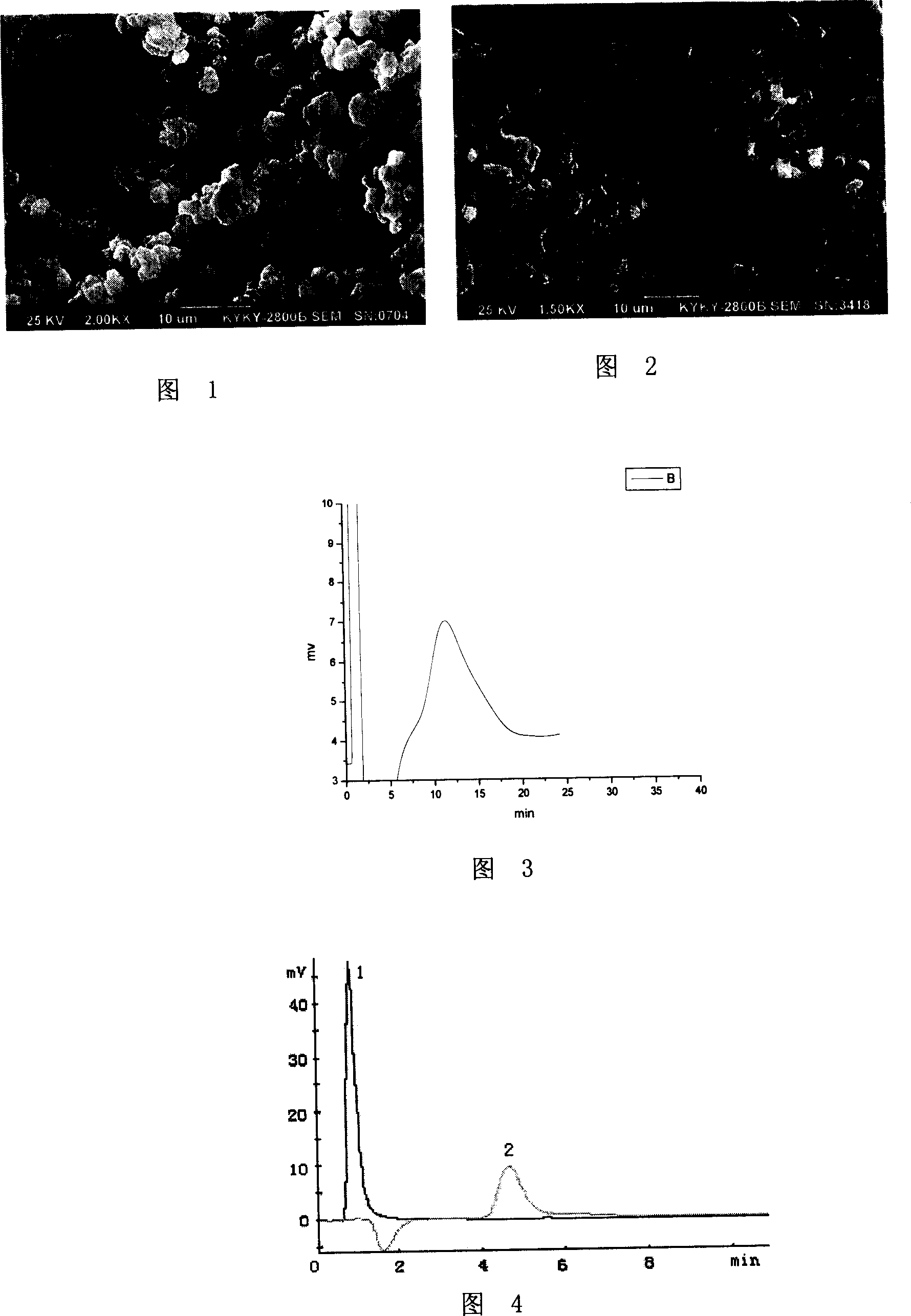

[0028] The scanning electron microscope showed that the through...

Embodiment 3

[0029] Embodiment 3: Preparation of epoxy resin matrix monolithic separation column

[0030] First put 6.5ml of polyvinyl alcohol-200 in the test bottle, then add 0.52g of 4,4-diaminodicyclohexylmethane to dissolve, and finally add 2.5lg of bisphenol A diglycidyl ether, the resulting solution is clear transparent. Pour the above glue into a polytetrafluoroethylene tube, seal and react at 80°C for 2 hours, then raise the temperature to 160°C and react for 2h, then slowly cool down to room temperature, and take it out to prepare the wet epoxy resin monolithic medium. The monolithic medium was firstly washed with water, then repeatedly washed with acetone, and finally vacuum-dried at 60° C. for 24 hours to obtain an epoxy resin matrix monolithic separation column.

[0031] Scanning electron microscopy shows that the through hole diameter is about 3 μm. For a 100mm×4.6mm i.d. column, when the flow rate is 1mL / min, the pressure drop is 1.9Mpa; when the flow rate is 2mL / min, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com