Transparency conductive film and preparation method thereof

A transparent conductive film, vacuum coating machine technology, applied in cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve problems such as low carrier injection efficiency, affecting device luminous performance, device failure, etc. The effect of saving non-renewable resources, high visible light transmittance, and improving luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The DM 450 vacuum coating machine of Beijing Instrument Factory is used to prepare IVO transparent conductive film by thermal evaporation method. The specific steps are as follows:

[0027] a. Blow dry the glass substrate cleaned with deionized water and acetone ultrasonically with dry nitrogen, put it into a vacuum chamber, and evacuate the vacuum chamber to a pressure lower than 5.0×10 -3 Pa, and then heat the glass substrate at a temperature of 70-350°C;

[0028] b. Fill the vacuum chamber with oxygen, the purity of the oxygen in the vacuum chamber is 99.999%, after filling the oxygen, control the pressure in the vacuum chamber to be 8×10 -3 ~2×10 -1 Within the range of Pa, the vacuum gauge and mass flow meter are used to monitor the vacuum degree of the oxygen filled in the vacuum chamber in real time;

[0029] c. In order to avoid the influence of substrate surface composition on IVO film formation characteristics, a layer of SiO is first grown on the substrate ...

Embodiment 2

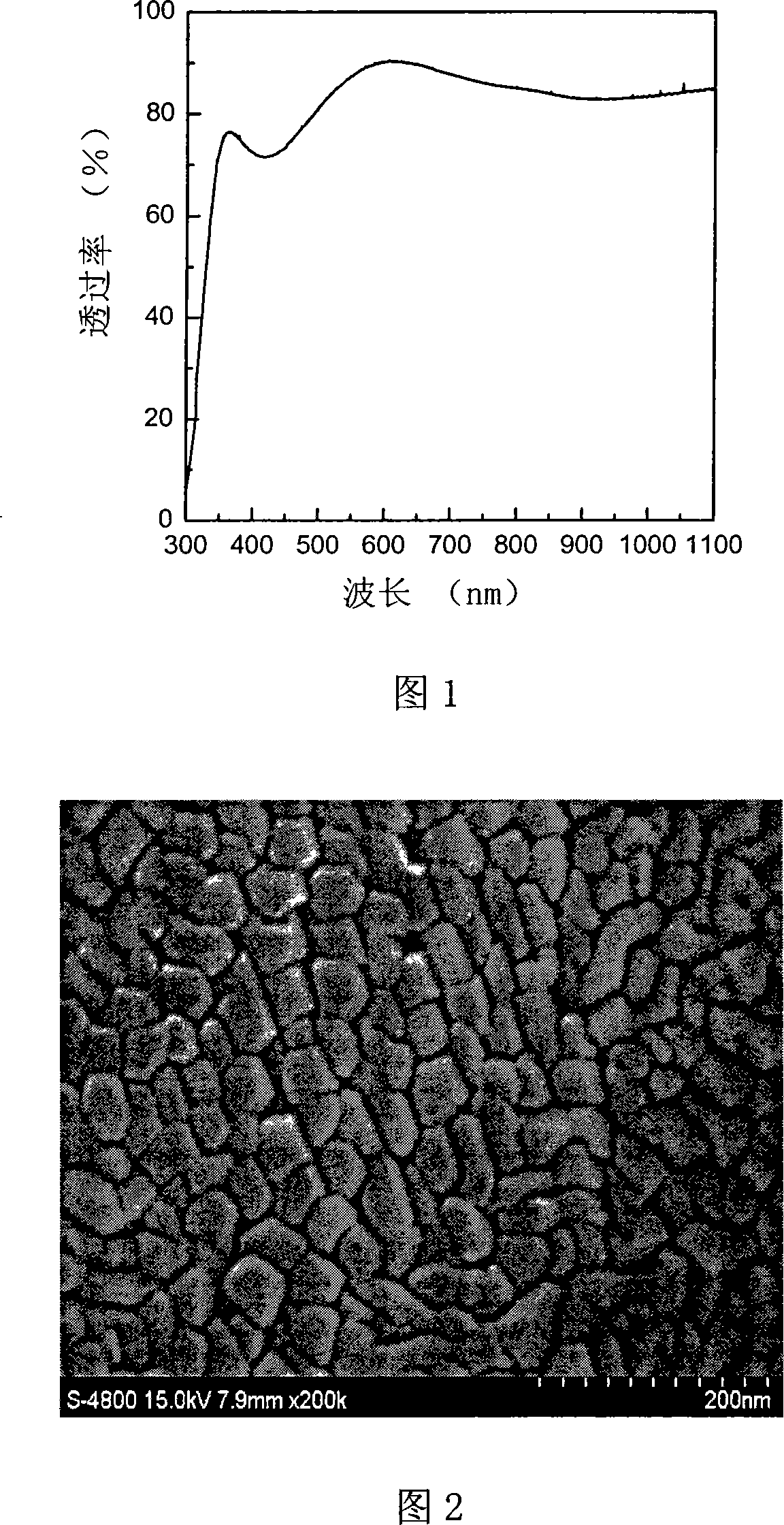

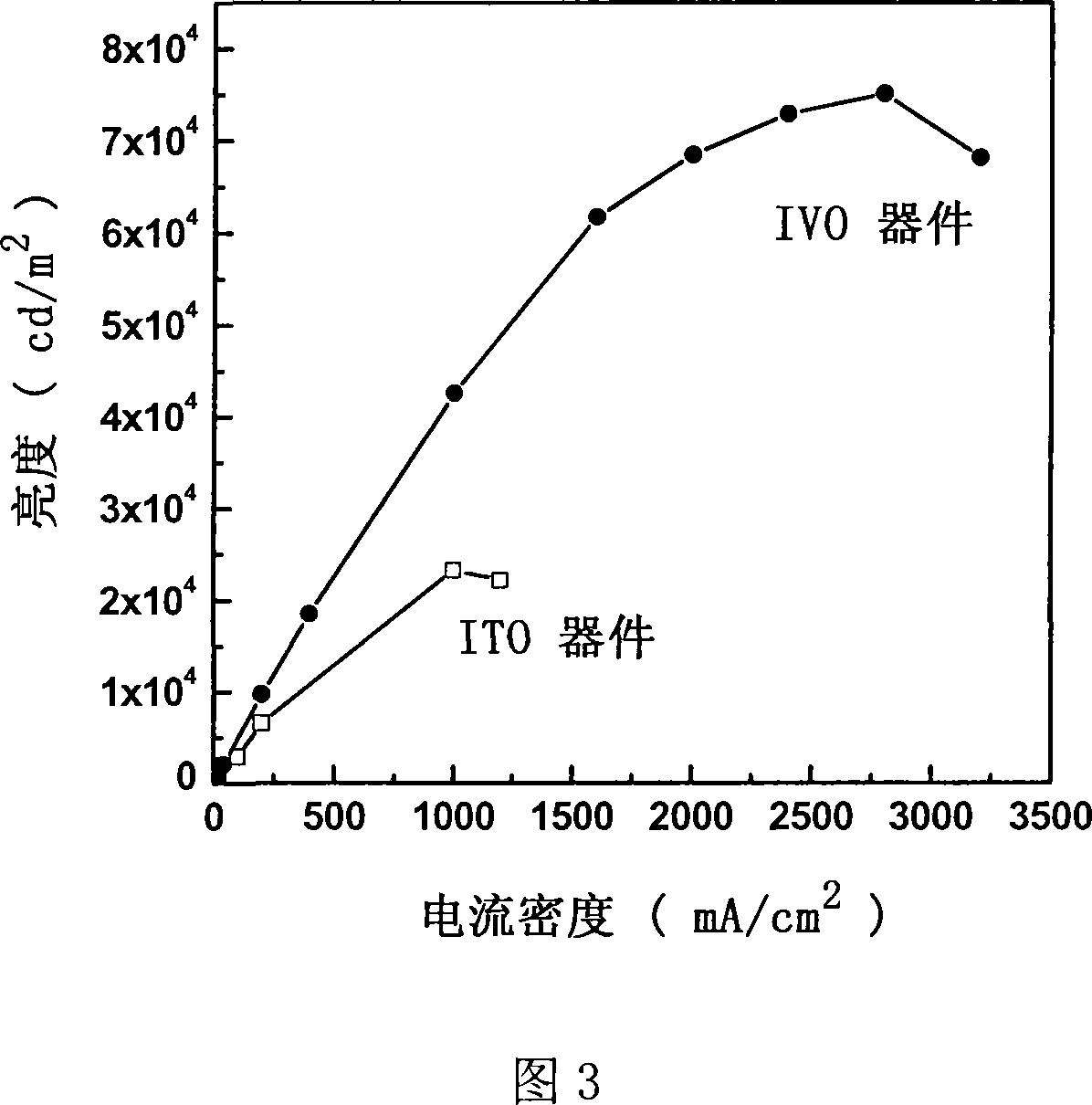

[0037] The ZZS700 box-type high-vacuum coating machine of Chengdu Vacuum Machinery Factory was used to prepare the IVO transparent conductive film by electron beam deposition technology, and the basic technical requirements for vacuum and substrate were the same as in Example 1. First grow a layer of Al on the glass substrate 2 o 3, thick 1 ~ 15nm. Then IVO was prepared on the glass substrate by electron beam thermal evaporation. The evaporation raw material is InV alloy (the mass ratio of metal V to In is 1:3~1:20), and the MDC-360 of MAXTEK Company is used to monitor the growth rate and film thickness of the film in real time. The evaporation rate is 0.05~2nm / s. The mass ratio of V to In after film formation can be 0.1-30% by adjusting the electron beam current and the working vacuum degree. The film thickness ranges from 20nm to 500nm. After the thin film is prepared, the annealing condition is 60-250° C. and the time is 10-300 minutes. Fig. 2 is the scanning electro...

Embodiment 3

[0039] Using In with a purity of 99.99% 2 o 3 Powder with 99.99% purity V 2 o 5 The powders are evenly mixed with each other (In 2 o 3 with V 2 o 5 The mass ratio is 98:2 to 80:20), and it is sintered into a target material. The target is used to deposit IVO thin film by magnetron sputtering technology. The substrate temperature is 200°C. Sputtering power is radio frequency target 0 ~ 500 watts. The sputtering rate is 0.04-1nm / s. By adjusting sputtering power and working vacuum, the mass ratio of V to In after film formation can be 0.1-30%. The surface resistance of the IVO thin film reaches ~15Ω / □, and the average visible light transmittance is higher than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com