Bicomponent automobile cathode electrophoresis paint and preparation method thereof

A cathodic electrophoretic coating, two-component technology, applied in electrophoretic coatings, coatings, devices for coating liquids on the surface, etc., to achieve the effects of good water resistance, excellent weather resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

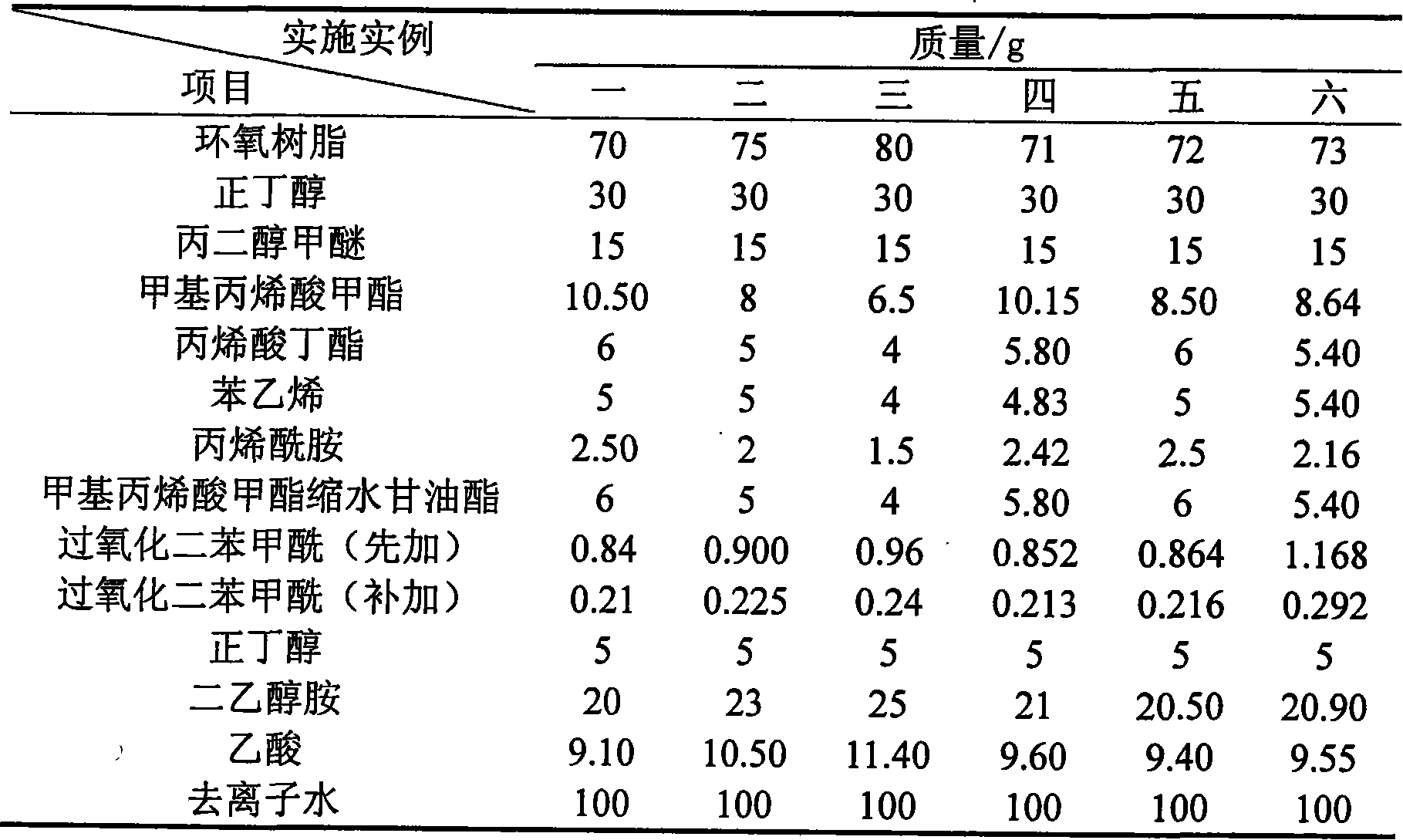

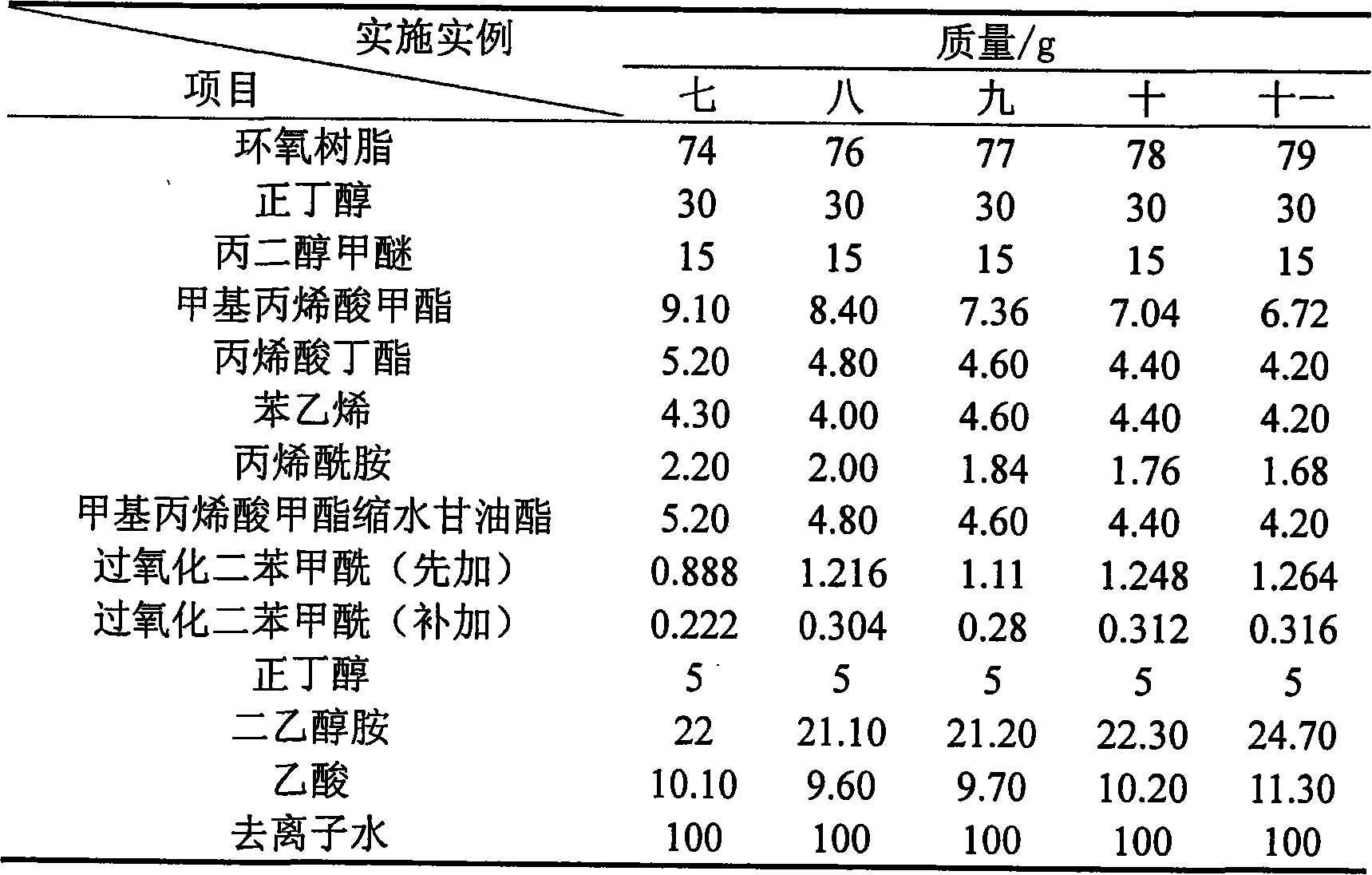

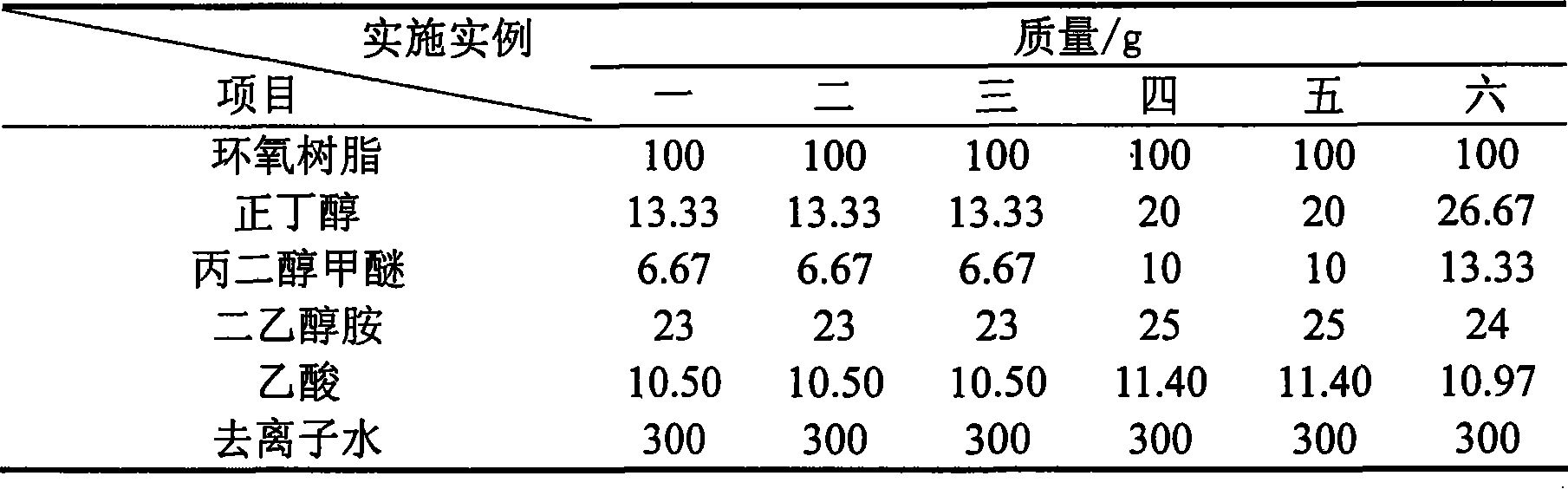

Embodiment 1

[0062] Add 70g of epoxy resin, 30g of n-butanol and 15g of propylene glycol methyl ether mixed solvent 45g in a 1000ml four-necked round bottom flask equipped with a condensing reflux tube, agitator and temperature-controlled oil bath heating device, and slowly heat up under stirring To 110°C, under the protection of nitrogen, mix 30g of mixed monomers of methyl methacrylate 10.50g, butyl acrylate 6g, styrene 5g, acrylamide 2.50g and glycidyl methacrylate 6g, and peroxidize Dissolve 0.84g of dibenzoyl in the mixed monomer, drop it into the reaction system at a rate of 1 drop / s at a stirring speed of 250 rpm, and add di A solution of 0.21 g of benzoyl and 5 g of n-butanol was heated to 115° C. for 4 hours to obtain a graft copolymer solution. Cool the obtained graft copolymer solution to 90°C, gradually increase the stirring speed to 500 rpm as the viscosity of the reaction system increases, add 20g of diethanolamine dropwise, and raise the temperature to 100°C for 2 hours afte...

Embodiment 2

[0067] Add 75g of epoxy resin, 30g of n-butanol and 15g of propylene glycol methyl ether mixed solvent 45g in a 1000ml four-necked round bottom flask equipped with a condensing reflux tube, agitator and temperature-controlled oil bath heating device, and slowly heat up under stirring To 110°C, under the protection of nitrogen, mix 25g of mixed monomers including 8g of methyl methacrylate, 5g of butyl acrylate, 5g of styrene, 2g of acrylamide and 5g of glycidyl methacrylate, and diphenyl peroxide Dissolve 0.90 g of formyl in the mixed monomer, add dropwise to the reaction system at a rate of 1 drop / s at a stirring speed of 250 rpm, and add diphenyl peroxide after the dropwise addition is completed within 2 hours A solution of 0.225 g of n-butanol and 5 g of n-butanol was heated to 115° C. for 4 hours to prepare a graft copolymer solution. Cool the obtained graft copolymer solution to 90 °C, gradually increase the stirring speed to 500 rpm with the increase of the viscosity of t...

Embodiment 3

[0072]In a 1000ml four-neck round bottom flask equipped with a condensing reflux tube, a stirrer and a temperature-controlled oil bath heating device, add 45g of a mixed solvent of 80g of epoxy resin, 30g of n-butanol and 15g of propylene glycol methyl ether, and slowly heat up under stirring To 110°C, under the protection of nitrogen, mix 20g of the mixed monomers of methyl methacrylate 6.50g, butyl acrylate 4g, styrene 4g, acrylamide 1.50g and glycidyl methacrylate 4g, and peroxidize Dissolve 0.96g of dibenzoyl in the mixed monomer, drop it into the reaction system at a rate of 1 drop / s at a stirring speed of 250 rpm, and add di A solution of 0.24 g of benzoyl and 5 g of n-butanol was heated to 115° C. for 4 hours to obtain a graft copolymer solution. Cool the obtained graft copolymer solution to 90 °C, gradually increase the stirring speed to 500 rpm with the increase of the viscosity of the reaction system, add 25 g of diethanolamine dropwise, and raise the temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com