Method for producing D-lactic acid and brood-cell lactobacillus special for the same

A technology of Bacillus sporogenes and lactic acid, applied in the field of producing D-lactic acid, can solve the problems such as the decrease of the optical purity of D-lactic acid, the degeneration of strains, the contamination of miscellaneous bacteria, etc., and achieve the effects of high vigor, high transformation rate and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

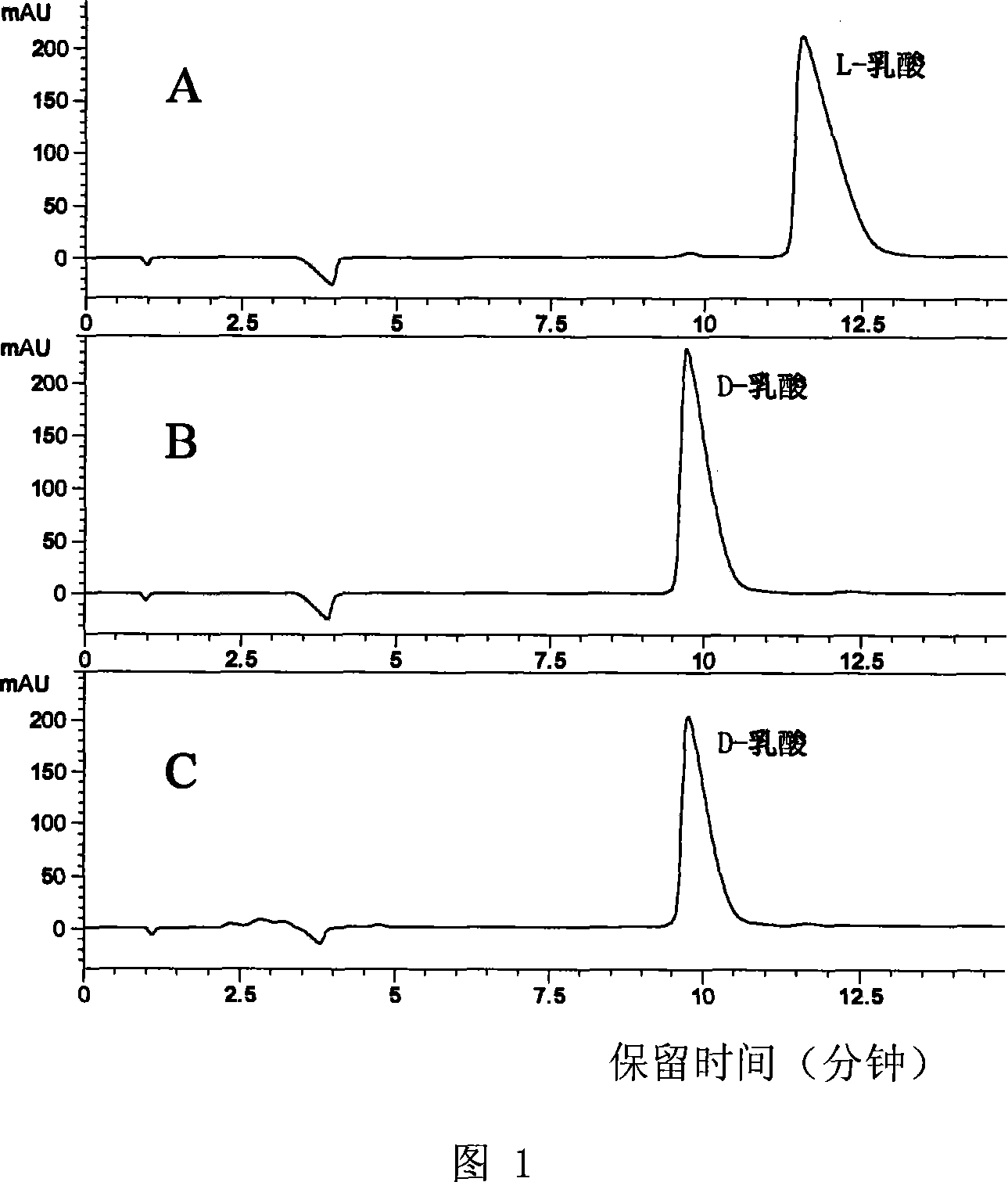

[0045] Example 1. Isolation, mutagenesis screening and identification of Lactobacillus inulinus (Sporolactobacillus inulinus) CASD CGMCC №2185

[0046] 1. Isolation and mutagenesis screening of the strain Sporolactobacillus inulinus CASD CGMCC №2185

[0047] Isolation and screening of bacterial strains: Collect the soil of an orchard in Pinggu, Beijing, weigh 5 grams and dissolve it in 100ml of normal saline, mix it well, dilute it with sterile water 100,000 times, spread it on MRS solid medium, and cultivate it at 37°C; after the colonies grow out , Some single colonies dissolve the calcium carbonate in the medium around the colony due to acid production, forming a transparent circle, pick a single colony with an obvious transparent circle, inoculate it in 10ml of fermentation medium, and culture it statically at 37°C for 72 hours. The detection method described in the embodiment is to detect the content of D-lactic acid in the fermentation broth. After multiple screenings, ...

Embodiment 2

[0064] Example 2, Utilize Sporolactobacillus inulinus (Sporolactobacillus inulinus) CASD CGMCC №2185 to ferment and produce D-lactic acid in a conical flask, cycle fermentation twice, and ferment for 48 hours each time, ferment at 35°C, and 90% of the Replace the fermentation broth with the same volume of fresh fermentation medium

[0065] The composition of each culture medium used in the present embodiment is as follows:

[0066] Slant medium: glucose 20 g / L, yeast extract 5 g / L, peptone 10 g / L, beef extract 10 g / L, dipotassium hydrogen phosphate 2 g / L, diammonium citrate 2 g / L, acetic acid Sodium 5 g / L, Tween 80 1 mL / L, magnesium sulfate heptahydrate 0.58 g / L, manganese sulfate tetrahydrate 0.25 g / L, calcium carbonate 15 g / L, agar powder 15 g / L, solvent is water; The pH of the slant medium is 6.5. It is sterilized at 115° C. for 20 minutes.

[0067] Seed medium: glucose 40 g / L, yeast extract 5 g / L, peptone 10 g / L, beef extract 10 g / L, dipotassium hydrogen phosphate 2 g / L,...

Embodiment 3

[0075] Example 3, using Sporolactobacillus inulinus (Sporolactobacillus inulinus) CASD CGMCC №2185 to ferment and produce D-lactic acid in a conical flask, cycle fermentation twice, and ferment and cultivate for 65 hours each time, ferment at 40°C, and 70% of the Replace the fermentation broth with the same volume of fresh fermentation medium

[0076] The composition of each culture medium used in the present embodiment is as follows:

[0077] The slant medium and seed medium are the same as in Example 2.

[0078] Fermentation medium: industrial glucose (Zibo Hongyu Industrial Sugar Co., Ltd.) 160 grams / liter, soybean meal hydrolyzate (soybean meal hydrolyzate preparation method is the same as Example 1) 150 grams / liter, corn steep liquor (Shanghai Xiwang Starch Sugar Co., Ltd.) 40 g / L, calcium carbonate 80 g / L, and water as the balance; the pH of the fermentation medium is 6. Sterilize at 115° C. for 20 minutes.

[0079] The method for producing D-lactic acid by fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com