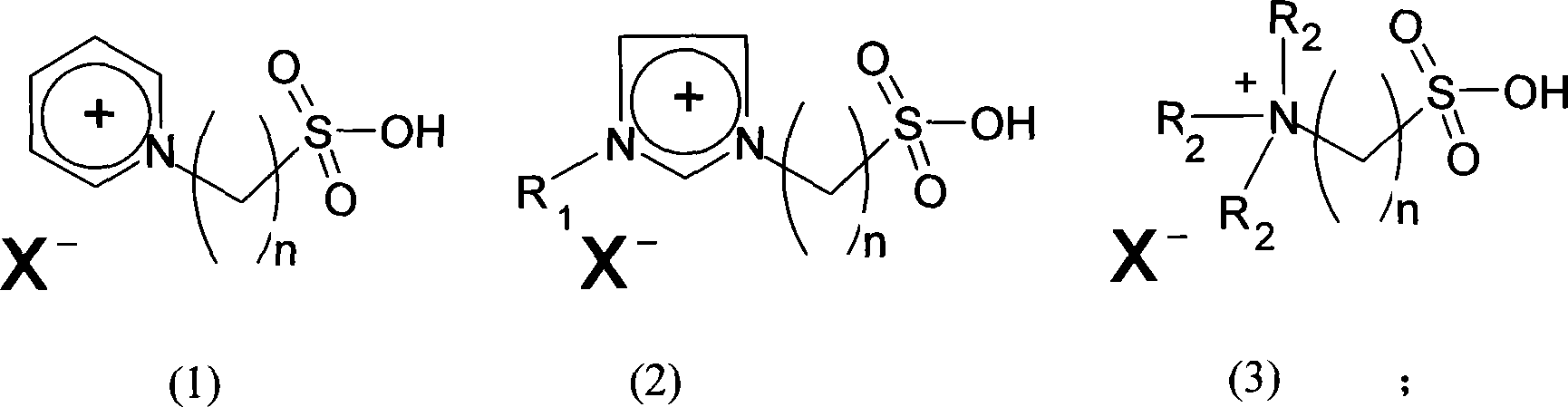

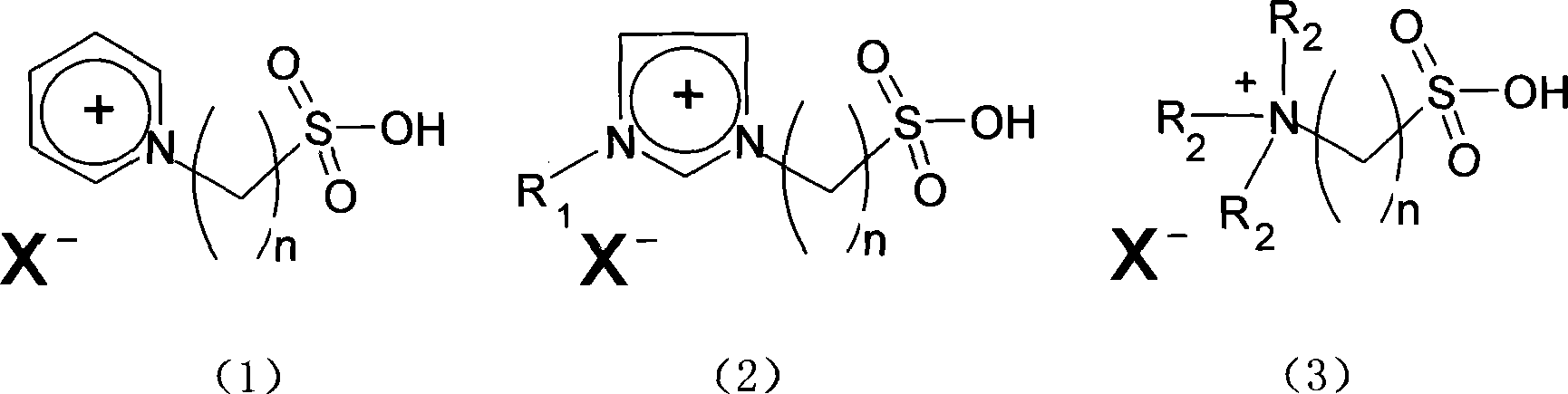

Brphinsted-Lewis acidic ionic liquid and application thereof in rosin polymerization reaction

An acidic ionic liquid and reaction technology, which is applied in the fields of chemical modification of natural resin, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve equipment corrosion and environmental pollution, solid acid catalyst structure Carbon, affecting product quality and other issues, to achieve the effect of good quality, no loss of acidity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Dissolve 27.2g of 1,4-butane sultone in 136g of ethyl acetate, raise the temperature to 40°C, and add 16.4g of N-methylimidazole dropwise. Washed with ethyl acetate and dried at 100° C. to obtain 42.7 g of white solid 1-(4-sulfonic acid) butyl-3-methylimidazole inner salt, yield 98%. Take 21.8 g of 1-(4-sulfonic acid) butyl-3-methylimidazolium inner salt, dissolve it in 43.6 g of water, add 9.9 g of hydrochloric acid with a mass concentration of 37%, dropwise, and react at 90°C for 3 hours Afterwards, dehydration under reduced pressure gave 24.4g pale yellow viscous liquid acidified internal salt, chlorinated 1-(4-sulfonic acid) butyl-3-methylimidazolium salt, yield 94%; Under nitrogen protection, 12.8g Mix 1-(4-sulfonic acid)butyl-3-methylimidazolium chloride with 10g zinc chloride and react at 100°C until the zinc chloride dissolves to obtain 22.8g Brnsted-Lewis acidic ionic liquid 1 -(4-sulfonic acid)butyl-3-methylimidazolium chloride zincate. Get 1.3g 1-(4-sulfon...

Embodiment 2

[0014] Mix 12.8g of 1-(4-sulfonic acid) butyl-3-methylimidazolium chloride with 9.8g of cuprous chloride, and react at 100°C under nitrogen protection until the cuprous chloride is dissolved to obtain 22.6g Brnsted-Lewis acidic ionic liquid 1-(4-sulfonic acid) butyl-3-methylimidazolium chlorocuprousate. Get 1.8g 1-(4-sulfonic acid) butyl-3-methylimidazolium chloride cuprous acid salt, 5g rosin and 40g cyclohexane react under reflux after 5 hours, cool to room temperature product, separate upper layer liquid, The upper layer liquid was decompressed to remove the solvent to obtain a polymerized rosin product with a softening point of 121°C (ring and ball method).

Embodiment 3

[0016] Dissolve 24.4g of 1,3-propane sultone in 200g of ethyl acetate, raise the temperature to 40°C, add 22g of N-propylimidazole dropwise, after the dropwise addition, keep the reaction for 4 hours, filter, and filter the cake with ethyl acetate After washing and drying at 100°C, 45 g of white solid 1-(3-sulfonic acid)propyl-3-propylimidazole inner salt was obtained, with a yield of 97%. Take 23.2 g of 1-(3-sulfonic acid) propyl-3-propyl imidazole inner salt, dissolve it in 55 g of water, add 9.9 g of hydrochloric acid with a mass concentration of 37%, and after the addition is completed, react at 90°C for 2 hours , dehydration under reduced pressure to get 24.7g pale yellow viscous liquid acidified inner salt, chlorinated 1-(3-sulfonic acid) propyl group-3-propylimidazolium salt, yield 92%; 13.4g chlorinated 1-(3 -sulfonic acid) propyl group-3-propylimidazolium salt mixed with 11g cupric chloride, under nitrogen protection, react until cupric chloride dissolves at 110 ℃, ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com