Method for producing calcium sulfide from calcium sulfate

A technology of calcium sulfate and calcium sulfide, applied in the fields of magnesium/calcium/strontium/barium sulfide/polysulfide, chemical industry, sustainable manufacturing/processing, etc., can solve the problem of reduced production capacity of sulfuric acid plant, multiple equipment, and fire resistance of separation equipment Difficult material life and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

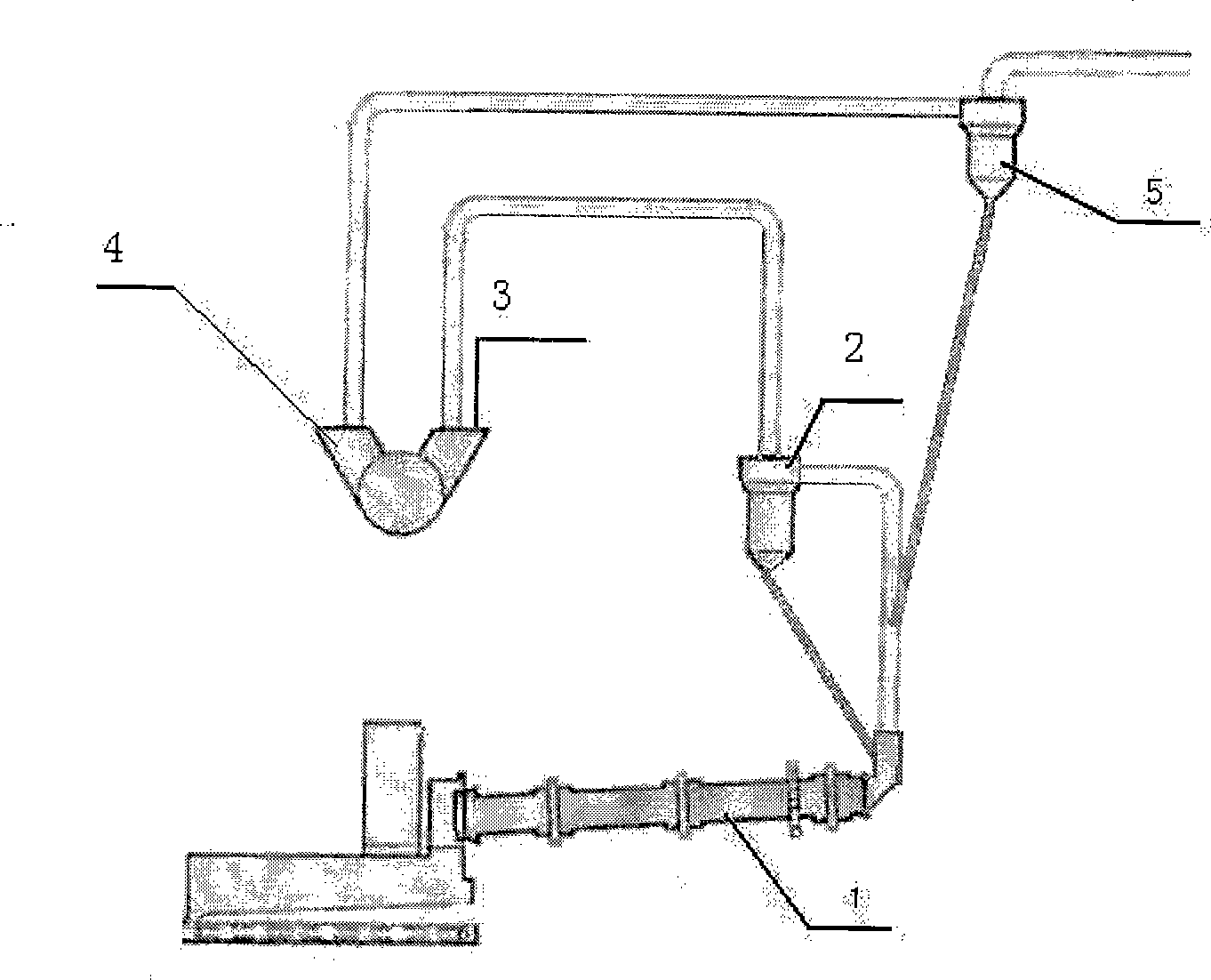

[0022] See accompanying drawing 1, the phosphogypsum that is piled up in the slag yard obtained in the production of wet-process phosphoric acid, such as the phosphogypsum that contains external moisture 9-13%, is directly added into the clinker that is commonly used in the clinker firing of the cement plant from the feeding port 3. The rotary hammer drying crusher 4 exchanges heat with the exhaust gas below 900°C from the rotary kiln 1 through the pipeline and the preheater 2, and then enters the cyclone separator 5, and the separated materials enter the lower preheater 2, and finally The material separated from the primary preheater 2 enters the falling rotary kiln 2 for reduction reaction to generate calcium sulfide. The gas passes through the drying crusher and the cyclone preheater to exchange heat with the solid, and the temperature of the gas exiting the uppermost cyclone separator is reduced to 120-200°C, and then it is emptied after removal and purification.

Embodiment 2

[0024] When the raw material used is directly discharged from the filter in the production of wet-process phosphoric acid, such as phosphogypsum containing more than 20% of external moisture, the cyclone preheater 2 in the implementation example 1 needs to be canceled, and the kiln 1 is directly piped Connect with drying crusher 4, the reason is that raw material moisture content high drying needs more heat, other is with implementing example 1.

Embodiment 3

[0026] Calcium sulfate is dried and made calcium sulfate hemihydrate or calcium sulfate anhydrous, and coke powder and other raw materials are added in embodiment 1 to meet the requirements of cement clinker formula, and one or more cyclone preheaters 2 are added. Method replaces Drying Crusher 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com