Microsphere for electronic papers and uses thereof

A technology of electronic paper and microspheres, applied in instruments, optics, identification devices, etc., can solve problems such as adverse effects of electrophoresis speed, high toxicity, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

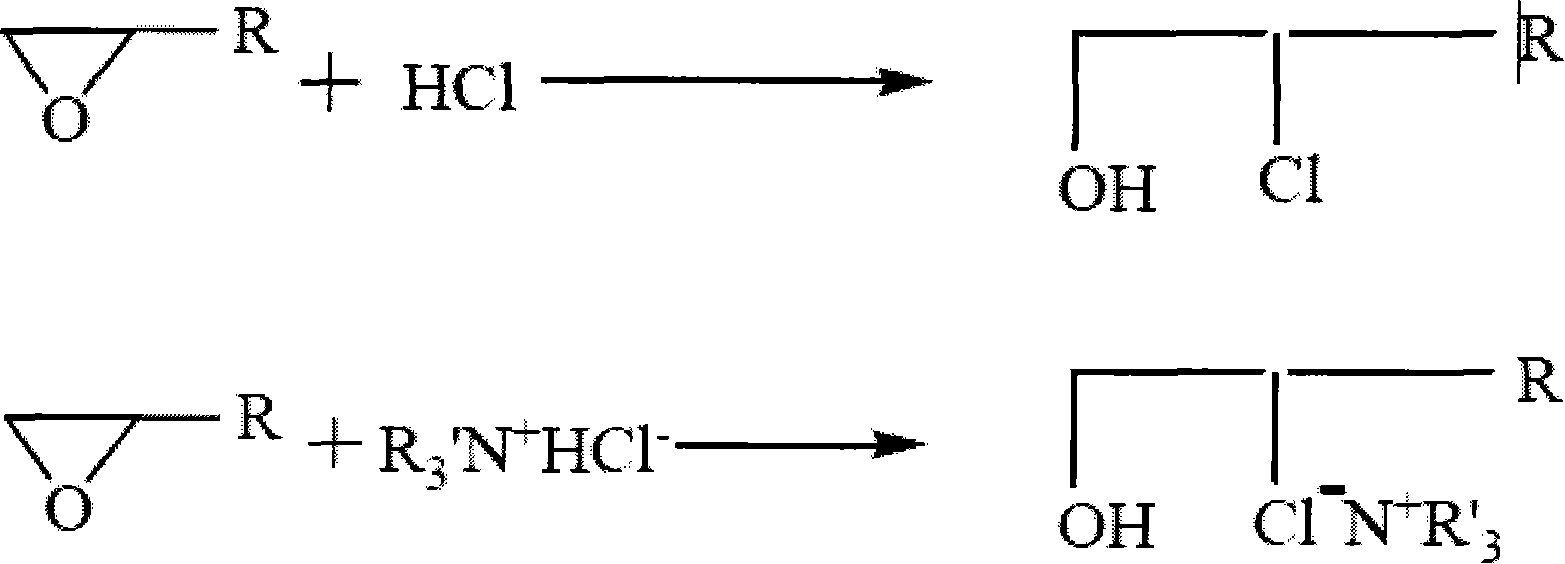

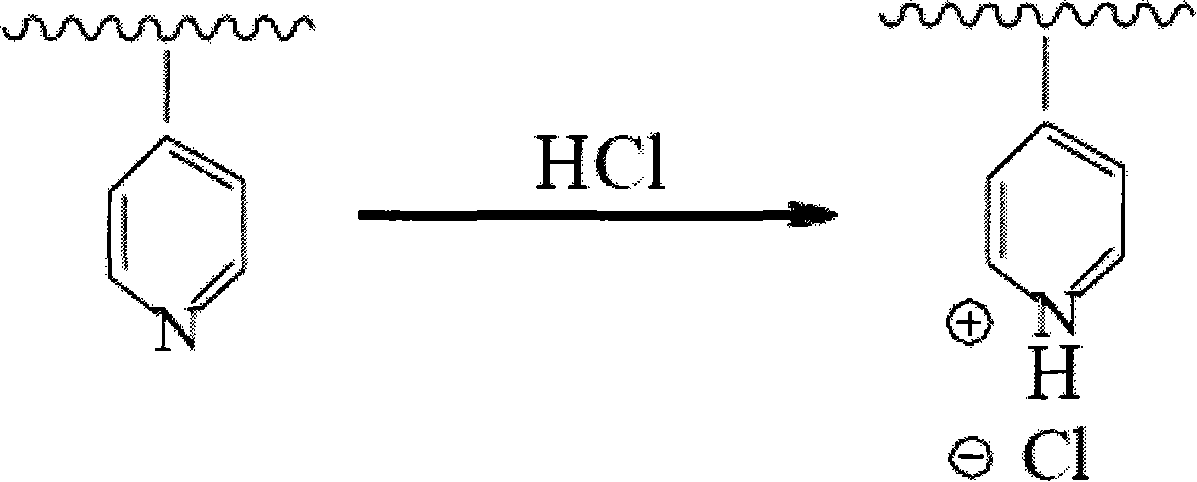

Method used

Image

Examples

Embodiment 1

[0073] Example 1: Using allyl methacrylate to synthesize a cross-linked core polymer with a lower limit of dosage. Its formula is listed in table 1:

[0074] Table 1

[0075]

[0076] In a 50ml beaker, dissolve the dye in the monomer mix. After fully stirring and dissolving, filter and set aside.

[0077] In a 250ml four-neck flask equipped with a stirring, condenser, air duct and thermometer, dissolve sodium dodecyl sulfate, potassium peroxodisulfate, and sodium bicarbonate in deionized water, and stir to dissolve. Introduce argon gas, keep the constant temperature at about 30°C, add the monomer mixture mixed with dye dropwise, and keep the stirring speed at 300rpm-400rpm. After the monomer is added dropwise, keep the dispersed state for 3hrs. Then heat up, keep warm at 70°C for 5hrs, keep warm at 80°C for 1hr, cool down, and the reaction ends.

Embodiment 2

[0078] Embodiment 2: Utilize allyl methacrylate to synthesize a cross-linked core polymer with an intermediate amount. Its formula is listed in table 2:

[0079] Table 2

[0080]

[0081] The synthesis process is similar to Example 1.

Embodiment 3

[0082] Example 3: Using allyl methacrylate to synthesize a cross-linked core polymer with an upper limit. Its formula is listed in table 3:

[0083] table 3

[0084]

[0085] The synthesis process is similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com