High ratio surface area grid solar integrated efficient light absorption dye sensitized solar battery

A high specific surface area, dye sensitization technology, applied in the direction of photovoltaic power generation, photosensitive equipment, circuits, etc., can solve the problems of high resistance of conductive glass substrates, improve battery efficiency, increase photoanodic light absorption, etc., to increase effective light collection Area, reduce the internal resistance of the battery, increase the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

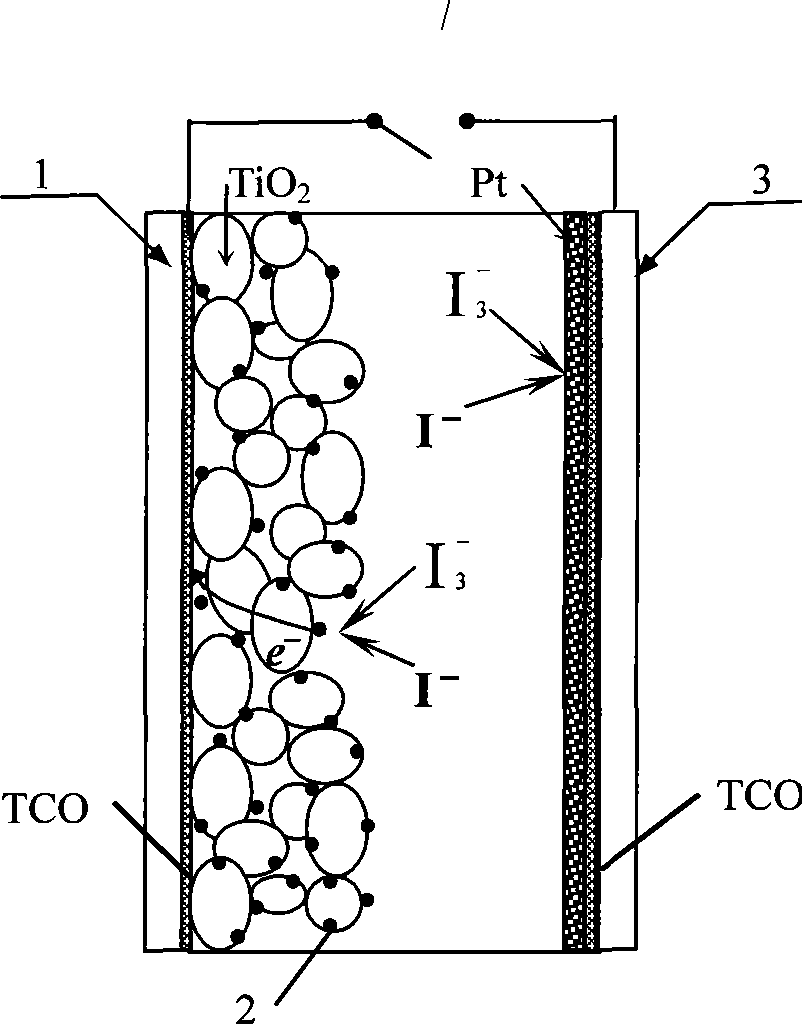

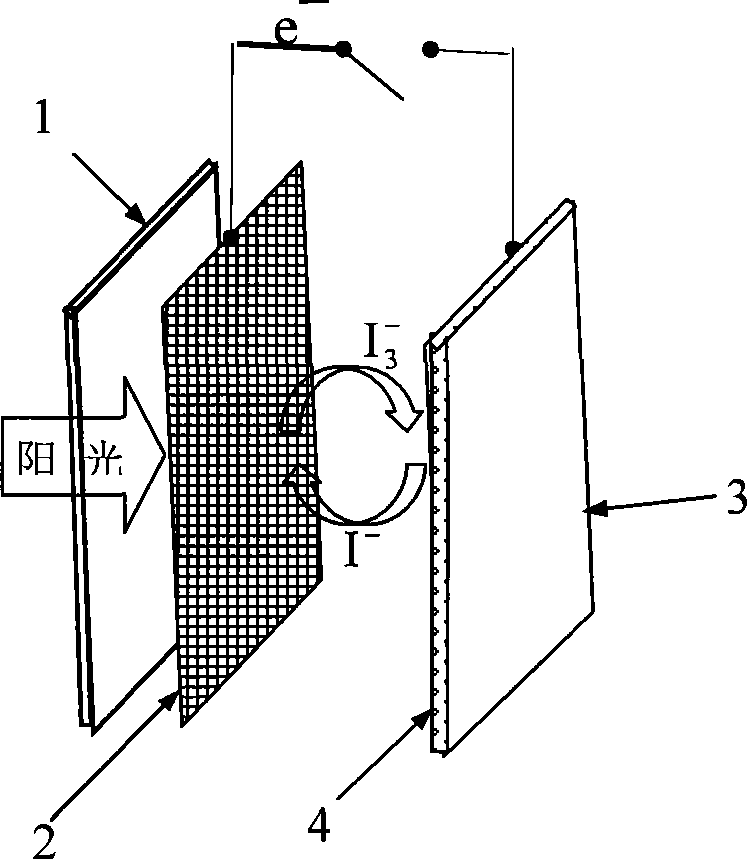

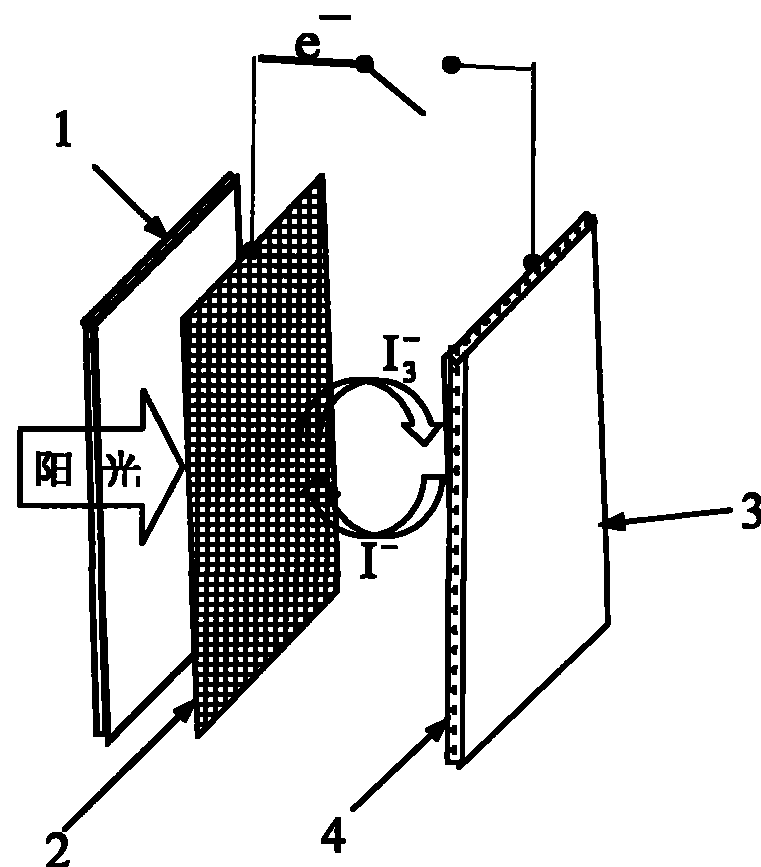

[0022] Put 12 grams of commercial nano-titanium dioxide P25 powder produced by Germany Degussa company into a mortar and grind, and add 4 ml of isopropanol solution containing 10% acetylacetone drop by drop, then add 10 ml of water drop by drop to continue grinding, and mix 0.2 ml Triton X-100 was added to the suspension to prepare a concentration of 54.54% TiO 2 Sol.

[0023] Use the pulling method to coat a 150 μm diameter, 60-mesh titanium metal mesh with a 15 μm thick titanium oxide film at a pulling speed of 10 mm per second, and reserve about 0.3 cm of the titanium metal mesh as a conductive electrode. Heat treatment for 30 minutes.

[0024] Put the coated titanium metal mesh into the 3×10 -5 mol / L N719 ruthenium organic dye ethanol solution, heated to 80°C and soaked for 3 hours, took it out, cleaned it with ethanol, and stored it in a dry and light-proof environment.

[0025] Immerse the titanium metal sheet in the solution containing 5mmol / L H by pulling method 2 ...

Embodiment 2

[0030] Mix 125mL of isopropyl titanate and 20mL of isopropanol evenly, put it into a separatory funnel, add dropwise to 750mL of deionized water containing 5.3mL of 70% nitric acid within ten minutes and stir vigorously. Continue to stir for 8 hours to form transparent nano-TiO 2 colloid solution, and then put it into a high-temperature and high-pressure reactor at a temperature of 200 ° C for 12 hours to react at a constant temperature, and the prepared nano-TiO 2 The sol was concentrated by rotary evaporation to a concentration of 45% TiO 2 Sol.

[0031] A 100 μm-diameter, 100-mesh nickel metal mesh with a thickness of 10 μm was used for a titanium oxide film by screen printing, and a nickel metal mesh of about 0.3 cm was reserved as a conductive electrode, and heat treated at 500° C. for 1 hour.

[0032] Put the coated nickel metal mesh into the 5×10 -5 mol / L N719 ruthenium organic dye ethanol solution, placed at room temperature for 72 hours, cleaned with ethanol after ...

Embodiment 3

[0038] Put 250mL of butyl titanate and 20mL of isopropanol into a separatory funnel after mixing evenly, add dropwise to 1500mL of deionized water containing nitric acid with a pH value of 1 within 20 minutes and stir vigorously. Continue to stir for 10 hours at ℃ to form transparent nano-TiO 2 colloid solution, and then placed in a high-temperature and high-pressure reactor at 230 ° C for 12 hours at a constant temperature, and the prepared nano-TiO 2 The sol was concentrated by rotary evaporation to a concentration of 60% TiO 2 Sol.

[0039] A 75 μm diameter, 200-mesh tungsten metal mesh with a thickness of 10 μm is used for titanium oxide film, and a tungsten metal mesh of about 0.3 cm is reserved as a conductive electrode, and heat treated at 500 ° C for 1 hour.

[0040] Put the coated tungsten metal mesh into the 5×10 -5 mol / L N719 ruthenium organic dye ethanol solution, placed at room temperature for 72 hours, cleaned with ethanol after taking it out, and stored in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com