Method for preparing polymer microsphere

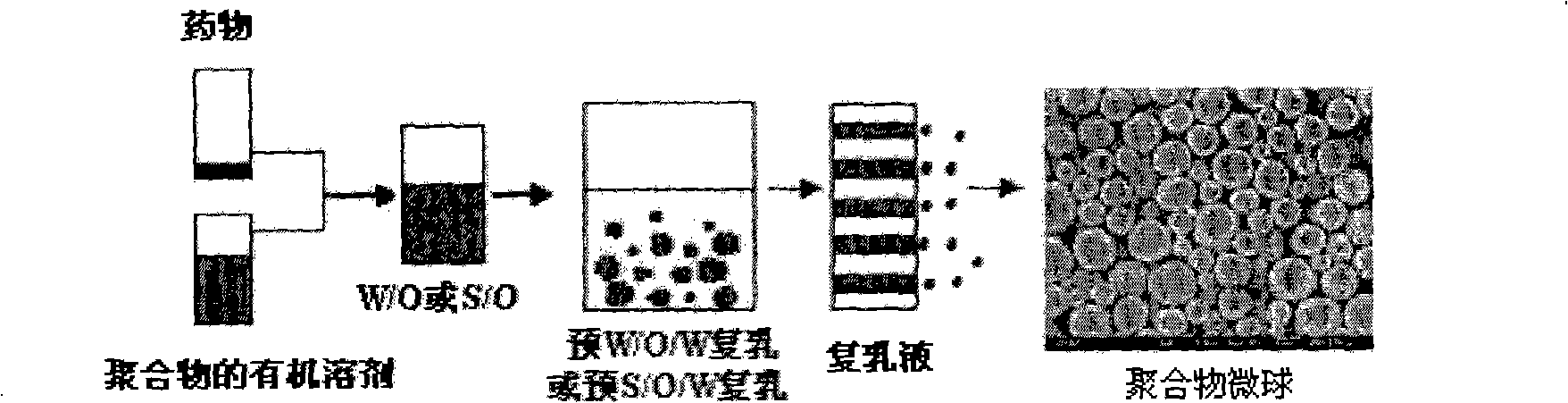

A technology of polymers and polymer materials, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of poor preparation repeatability, inability to embed hemoglobin, and difficulty in controlling particle size and other problems, to achieve the effect of simple operation and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

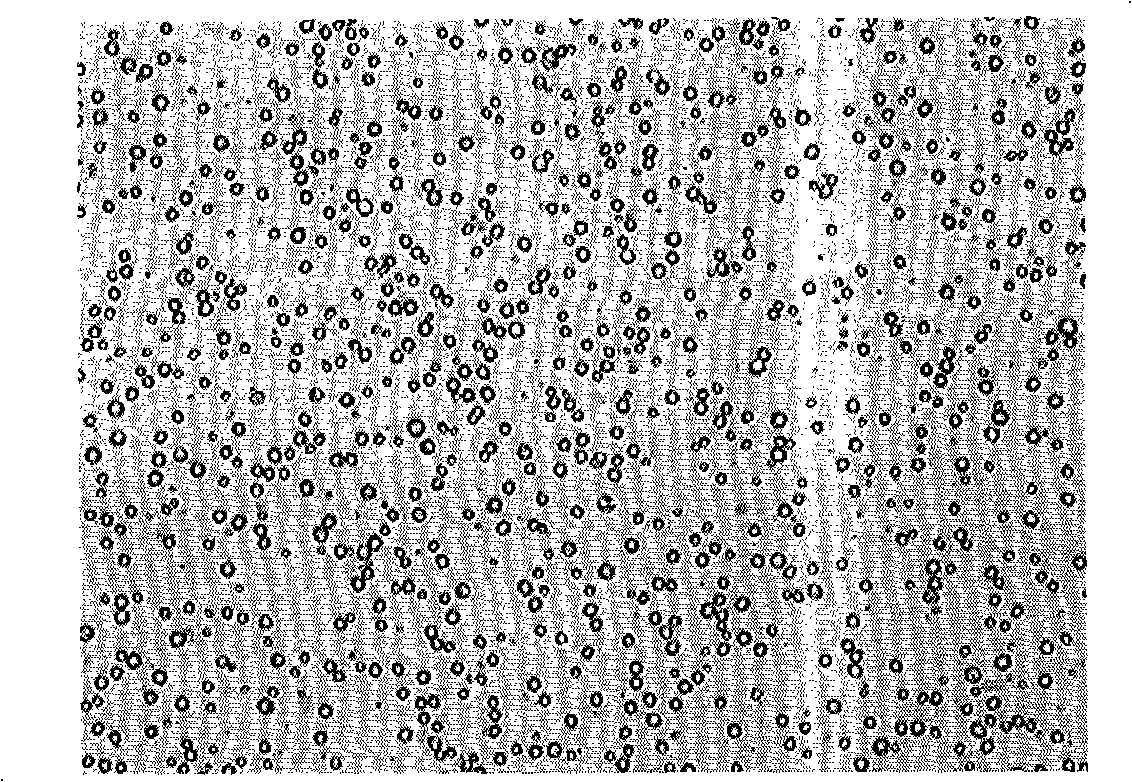

[0050] The hydrophilic SPG membrane with a pore size of 5.2 μm was soaked in water to fully wet the porous membrane. Dissolve 10 mg of lysozyme in 2 mL of deionized water as the inner water phase, and dissolve 0.2 g of PLGA membrane material (molecular weight: 30,000) in 4 mL of dichloromethane as the oil phase. Mix the inner water phase with the oil phase, and ultrasonically emulsify for 15 seconds in an ice-water bath to obtain W / O colostrum. This colostrum is added in the 1%wt PVA aqueous solution of 40mL, magnetic stirring 300rpm stirs 30s to prepare pre-multiplex emulsion, then this pre-multiplex emulsion is pressed through the microporous membrane device under the operating pressure of 300kPa, obtains multi-emulsion ( Optical micrograph of complex emulsion figure 2 Shown), the time for the emulsion to pass through the membrane is less than 1s, and then the double emulsion is stirred at room temperature for 24 hours to remove the organic solvent methylene chloride, and ...

Embodiment 2

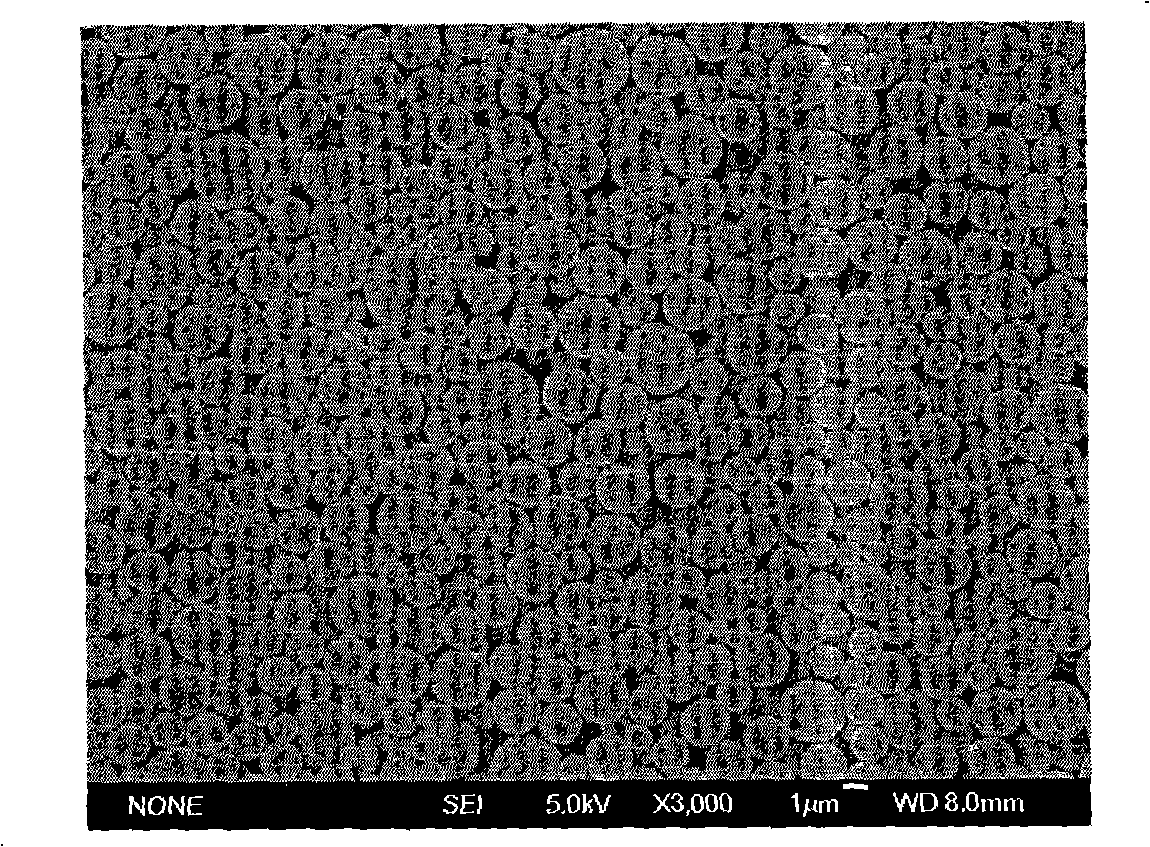

[0054] The hydrophilic SPG membrane with a pore size of 5.2 μm was soaked in water to fully wet the porous membrane. Dissolve 0.2g of PLGA membrane material (molecular weight: 30,000) in 4mL of dichloromethane as the oil phase, then add 10mg of lysozyme solid particles into the oil phase, and ultrasonically emulsify in an ice-water bath for 15s to obtain the S / O type initial phase. milk. The colostrum was added to 40mL of 1%wt PVA aqueous solution, magnetically stirred at 300rpm for 30s to prepare a pre-multiplex emulsion, and then the pre-multiplex emulsion was pressed through a microporous membrane device at an operating pressure of 300kPa to obtain a multi-emulsion, Stir the double emulsion at room temperature for 24 hours to remove the organic solvent dichloromethane, and then centrifuge and wash to obtain drug-loaded microcapsules. The obtained microcapsules were vacuum-dried for 48 h to obtain finished microcapsules. The electron micrograph of the microcapsule obtained...

Embodiment 3

[0056] The hydrophilic SPG membrane with a pore size of 5.2 μm was soaked in water to fully wet the porous membrane. With 0.8ml of 2mg / mL hepatitis B surface antigen solution as the inner aqueous phase, the copolymer of 0.2g polylactic acid-polyglycolic acid and polyethylene glycol (molecular weight 40,000, the ratio of polylactic acid and polyglycolic acid is 50 / 50, the mass fraction of polyethylene glycol is 20%) was dissolved in 4mL of dichloromethane, as the oil phase, then the inner water phase was added to the oil phase, ultrasonic emulsification in ice-water bath for 15s, to obtain W / O type colostrum. Add the colostrum to 40mL of 1%wt PVA in 0.9wt%NaCl aqueous solution, magnetically stir at 300rpm and stir for 30s to prepare the pre-multiplex emulsion, and then press the pre-multiplex emulsion through the microporous membrane device under the operating pressure of 300kPa , to obtain a double emulsion, and then stir the double emulsion at room temperature for 24 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com