Reaction for preparing hydroxyacetone by selectively dewatering natural glycerol and catalyst

A natural glycerin and catalyst technology, applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, carbon-based compound preparation, etc., can solve the problems of easy muddy active components, easy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0012]Weigh 15g of H-ZSM-5 raw powder with silicon-aluminum ratio of 25, 50, 75, 100 and 360, calcinate at 550°C for 3 hours, and cool to room temperature to prepare H-ZSM-5(X) catalyst. After tableting and granulation, it is used for the reaction of glycerol dehydration to acrolein.

[0013] Selective dehydration reaction of glycerol with 20% glycerol aqueous solution as raw material, LHSV is 0.15h -1 , The dehydration reaction temperature is 300°C. The reaction results are shown in Table 1.

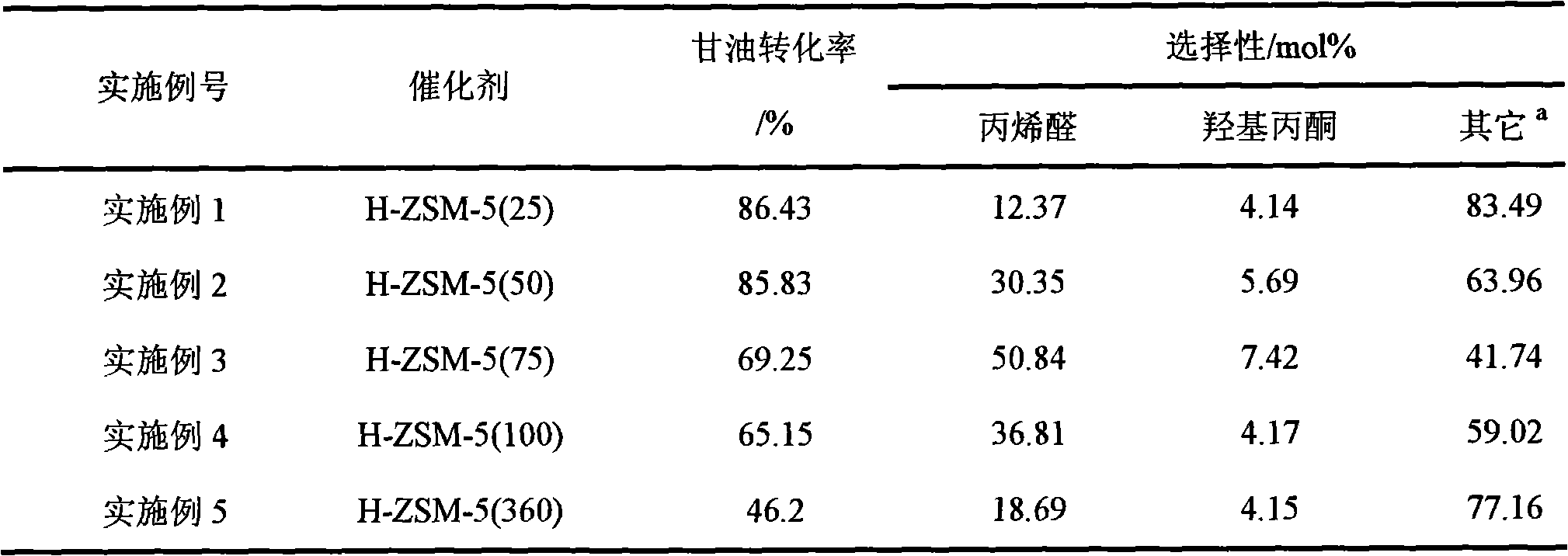

[0014] The reaction result of table 1 embodiment 1~5

[0015]

[0016] a : Including by-products such as formaldehyde, acetaldehyde, acetic acid, benzene and phenol.

Embodiment 6~10

[0018] Weigh 10 g of H-ZSM-5 raw powder with a silicon-aluminum ratio of 75, and exchange it with 0.2 mol / L metal salt solution under acidic conditions for 3 times by boiling and refluxing, each time is 4 hours, and the amount of solution added each time is 80 mL. Afterwards, it was washed with deionized water, dried at 110°C, and then baked in a muffle furnace at 600°C for 3 hours to obtain M-ZSM-5(75). The content of the active metal component in the prepared catalyst was 1.0 wt%. After tableting and granulation, it is used for the reaction of glycerol dehydration to acrolein. Reaction technique and condition are with embodiment 1. The reaction results are shown in Table 2

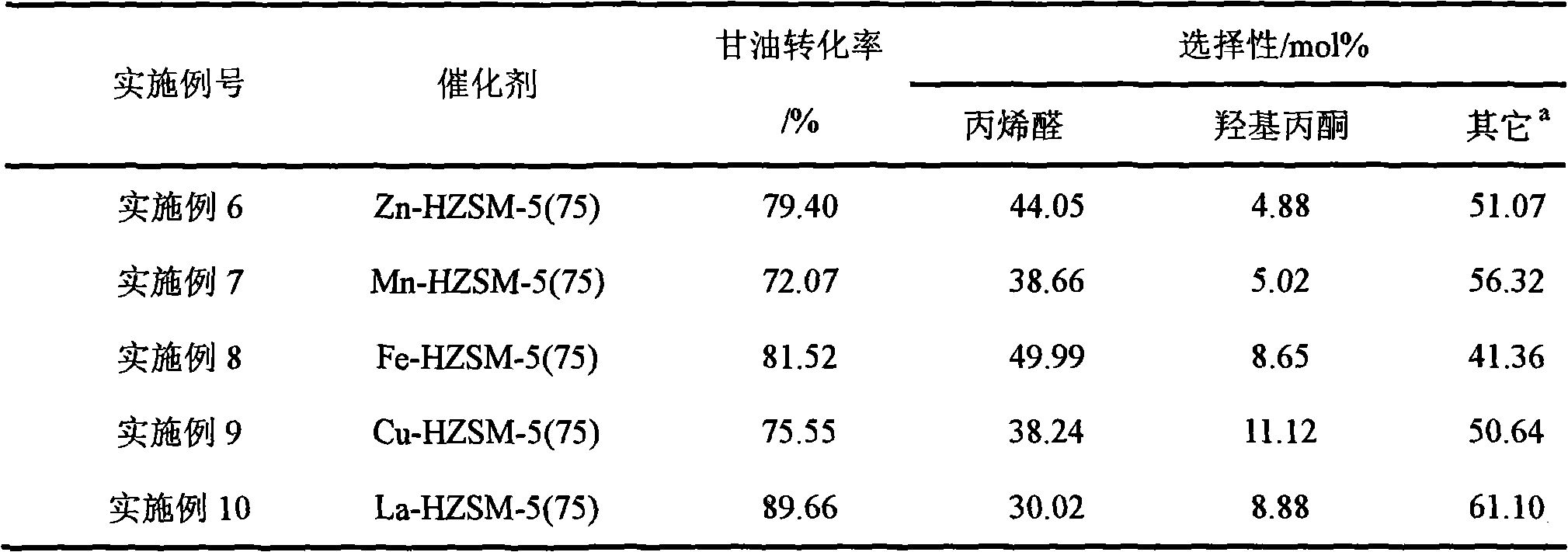

[0019] The reaction result of table 2 embodiment 6~10

[0020]

[0021] a : Including by-products such as formaldehyde, acetaldehyde, acetic acid, benzene and phenol.

Embodiment 11~15

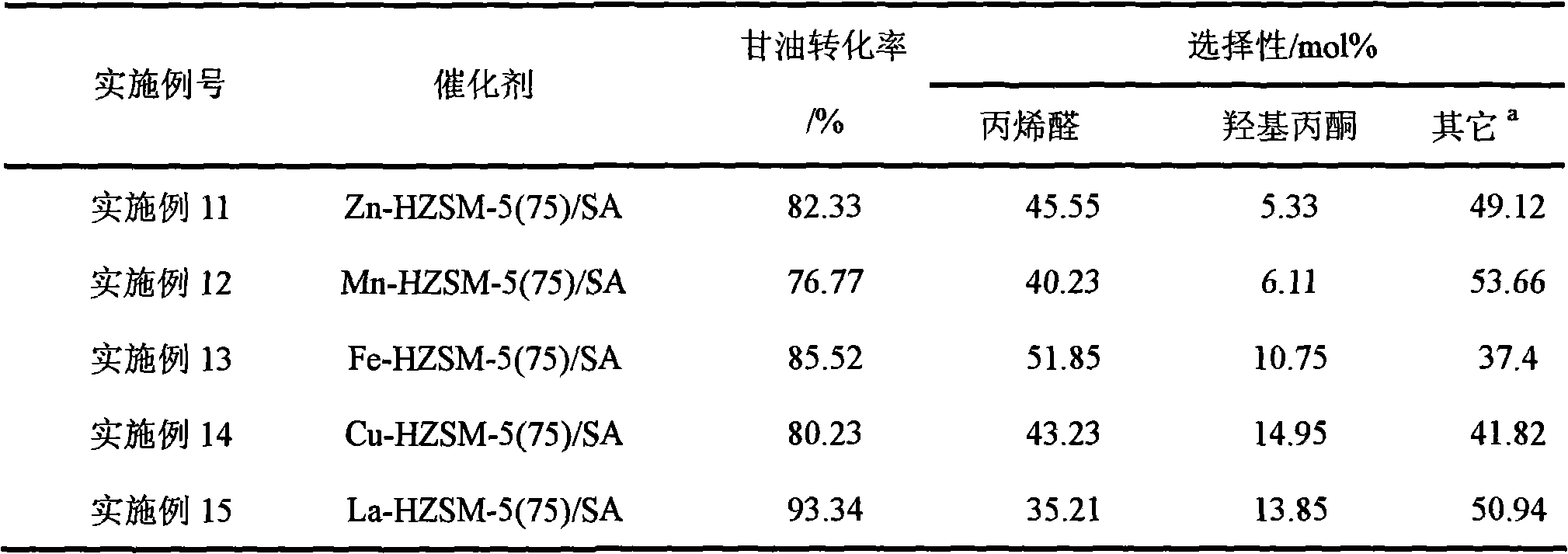

[0023] Accurately weigh 28.8g 33.3% silica sol, 12g NaOH particles, 6.6g Al 2 (SO 4 ) 3 18H 2 O powder and 192g H 2 O, move the silica sol into a three-necked flask, add NaOH solution, heat until clarified, then add Al 2 (SO 4 ) 3 solution, stirred at constant boiling for 2 hours, cooled to room temperature, and adjusted the pH value to 6.5 to obtain amorphous silica-alumina gel; weigh 10g of H-ZSM-5 raw powder with a silica-aluminum ratio of 75, and add 8g of amorphous silica-alumina gel After mixing, reflux and exchange with 0.2mol / L metal salt solution under boiling condition for 4 hours, add 100mL of solution, wash with deionized water after exchange, dry at 110°C, and put into 600°C muffle furnace The M-ZSM-5(75) / SA catalyst can be prepared by calcining for 3h. The content of amorphous silica-alumina in the prepared catalyst is 16wt%, and the content of metal is 1.5wt%.

[0024] Reaction technology and reaction condition are with embodiment 1. The reaction result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com