Collagen fiber stem grafting tannic acid and method for loading palladium catalyst

A collagen fiber and palladium catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, fiber processing, etc., can solve the problems of unseen industrial applications, poor mechanical properties of natural polymer materials, and difficult industrial catalytic systems for supported catalysts. and other problems, to achieve the effect of good reusability, good chemical stability, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

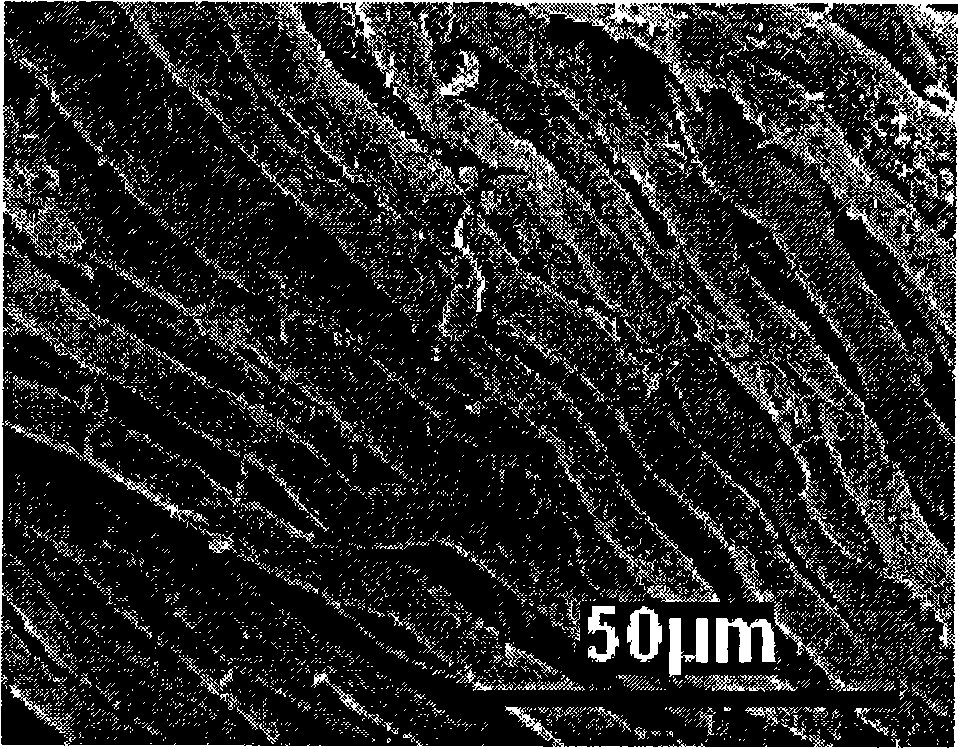

[0043] Select untanned pigskin scraps from tanneries as raw materials, grind them to a particle size of 0.5-2mm, and then wash them fully with deionized water to obtain pigskin collagen fibers with a moisture content of 80%, weigh 100 parts of the collagen fibers and add them to Dissolve in 100 parts of deionized water, then add 30 parts of tea tannin and react at room temperature for 2 hours, then add 7 parts of glutaraldehyde, and use hydrochloric acid with a concentration of 0.1mol / L to control the pH of the system to 7.0, and then stir and react at room temperature for 2 hours. The temperature was raised to 35° C., stirred and reacted for 3 hours, filtered and fully washed with deionized water to obtain tea tannin-grafted collagen fibers (CFGT).

[0044] Add 150 parts of deionized water to 100 parts of collagen fiber grafted tea tannins with a water content of 80%, stir for 2 hours, add 3 parts of palladium chloride (dissolved with 50 parts of deionized water earlier), and ...

Embodiment 2

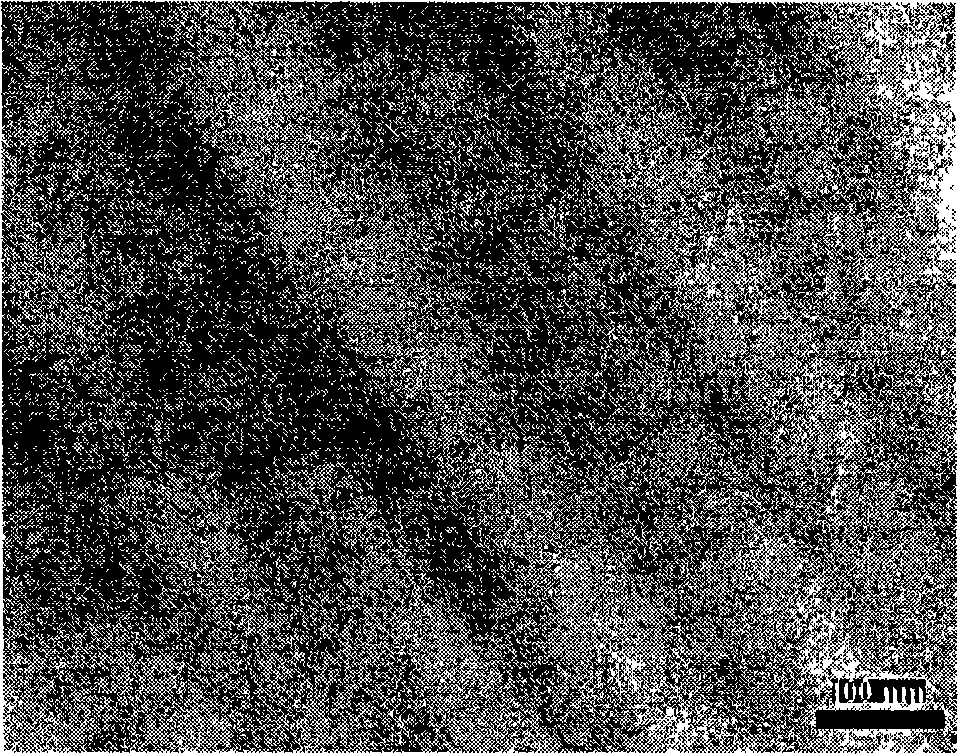

[0047] In 100 parts of collagen fiber grafted tea tannin loaded palladium catalysts with a moisture content of 80% prepared in Example 1, 200 parts of 0.1mol / L sodium borohydride solution was added, and reacted for 2 hours at a temperature of 35° C., filtered And wash with absolute ethanol, and then vacuum-dry at 35 DEG C for 8 hours to obtain palladium nano-catalyst supported by collagen fiber grafted tea tannin with a particle diameter of 2-8 nm.

[0048] The transmission electron micrograph of the catalyst is shown in figure 2 As shown, it can be seen from the figure that the particle size of the palladium nanoparticles loaded on the collagen fibers is 2-3 nm.

Embodiment 3

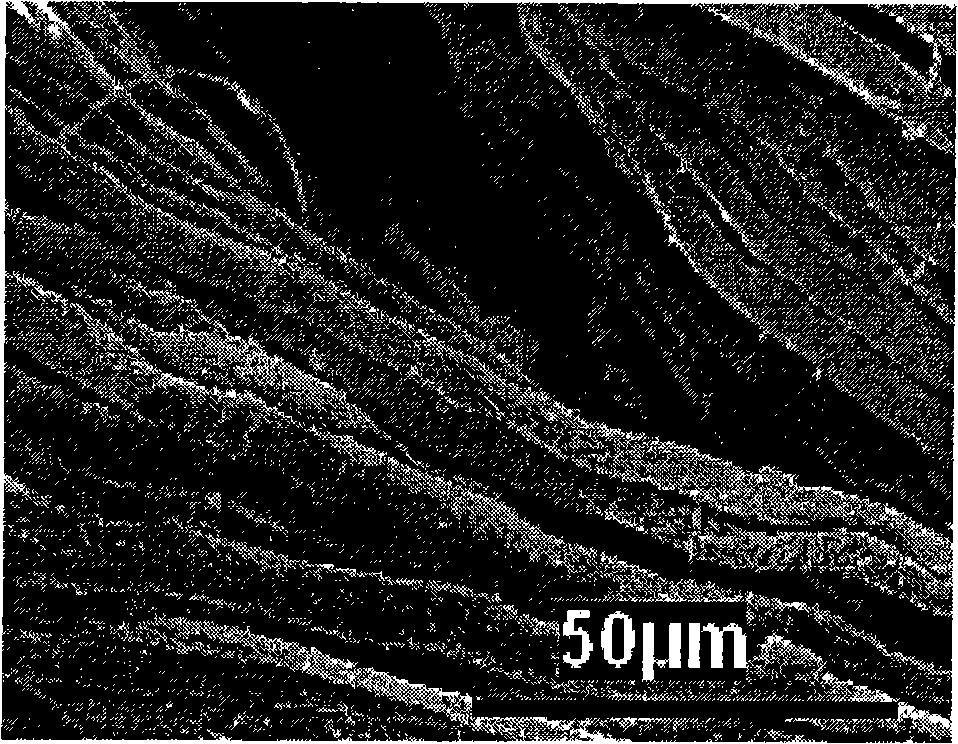

[0050] Select untanned cowhide scraps from tanneries as raw materials, crush them to a particle size of 0.5-2mm, and wash them thoroughly with deionized water to obtain cowhide collagen fibers with a moisture content of 80%. Weigh 100 parts of the collagen fiber and add it to 300 parts of deionized water to dissolve, then add 50 parts of tea tannin to react at room temperature for 3 hours, then add 6 parts of formaldehyde, and use hydrochloric acid with a concentration of 0.1mol / L to control the pH of the system to 5.0. After stirring and reacting for 3 hours, the temperature was raised to 30° C., stirred and reacted for another 2 hours, filtered and fully washed with deionized water to obtain tea tannin-grafted collagen fibers (CFGT).

[0051] Add 200 parts of deionized water to 100 parts of collagen fiber grafted tea tannins with a water content of 80%, stir for 4 hours, add 6 parts of palladium acetate (dissolved with 50 parts of deionized water earlier), and use a concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Heat denaturation temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com