Method for preparing undenatured collagen from fish scale of fresh water fish

A technology of collagen and fish scales, which is applied in the field of preparing undenatured collagen, can solve the problems of long extraction period, difficulty in industrialization, and serious pollution of three wastes, and achieve the effects of shortening the extraction period, high safety, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

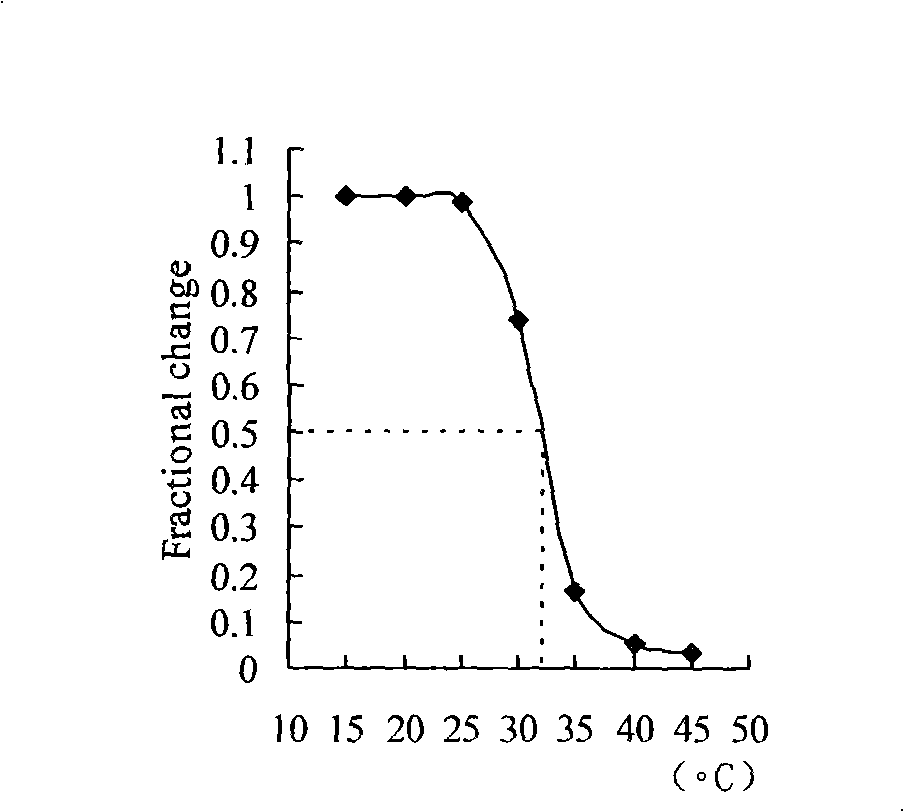

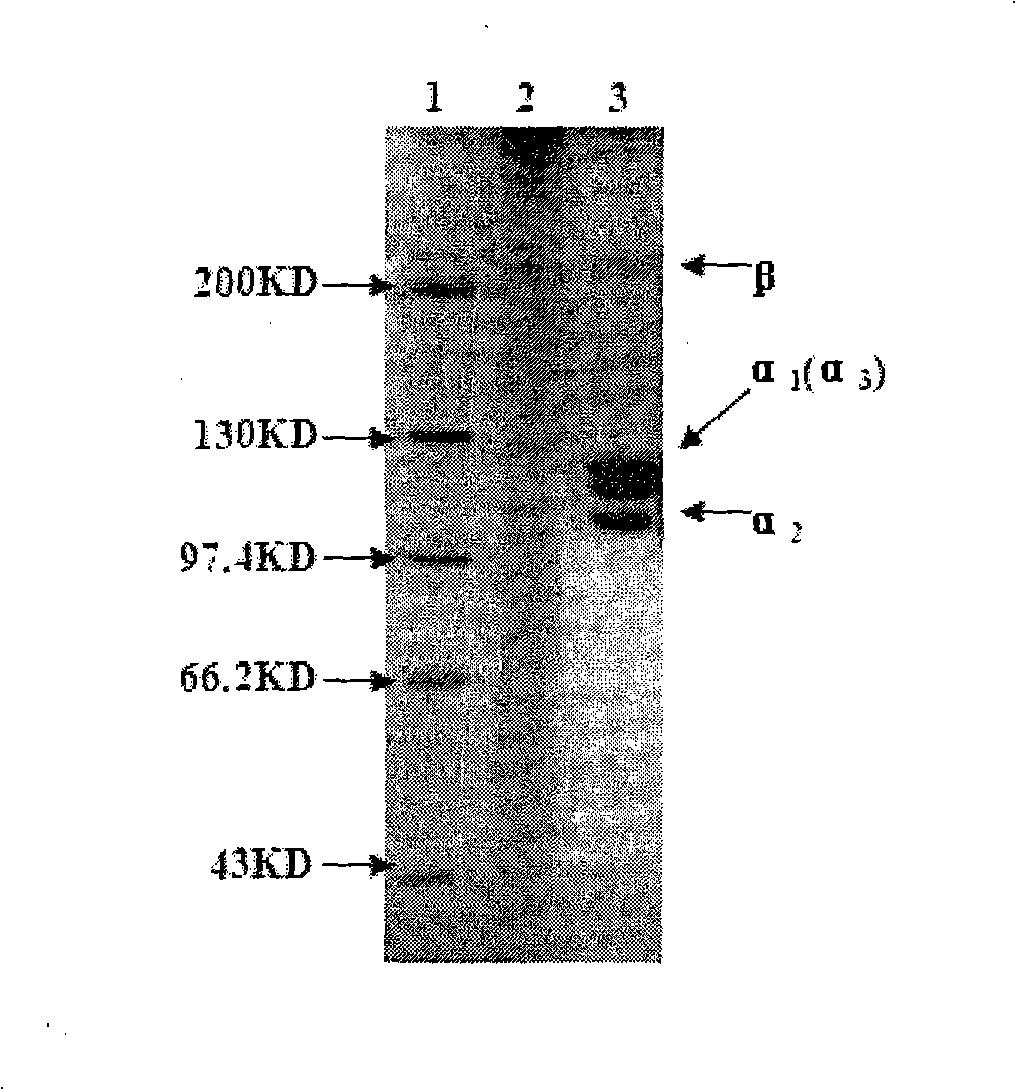

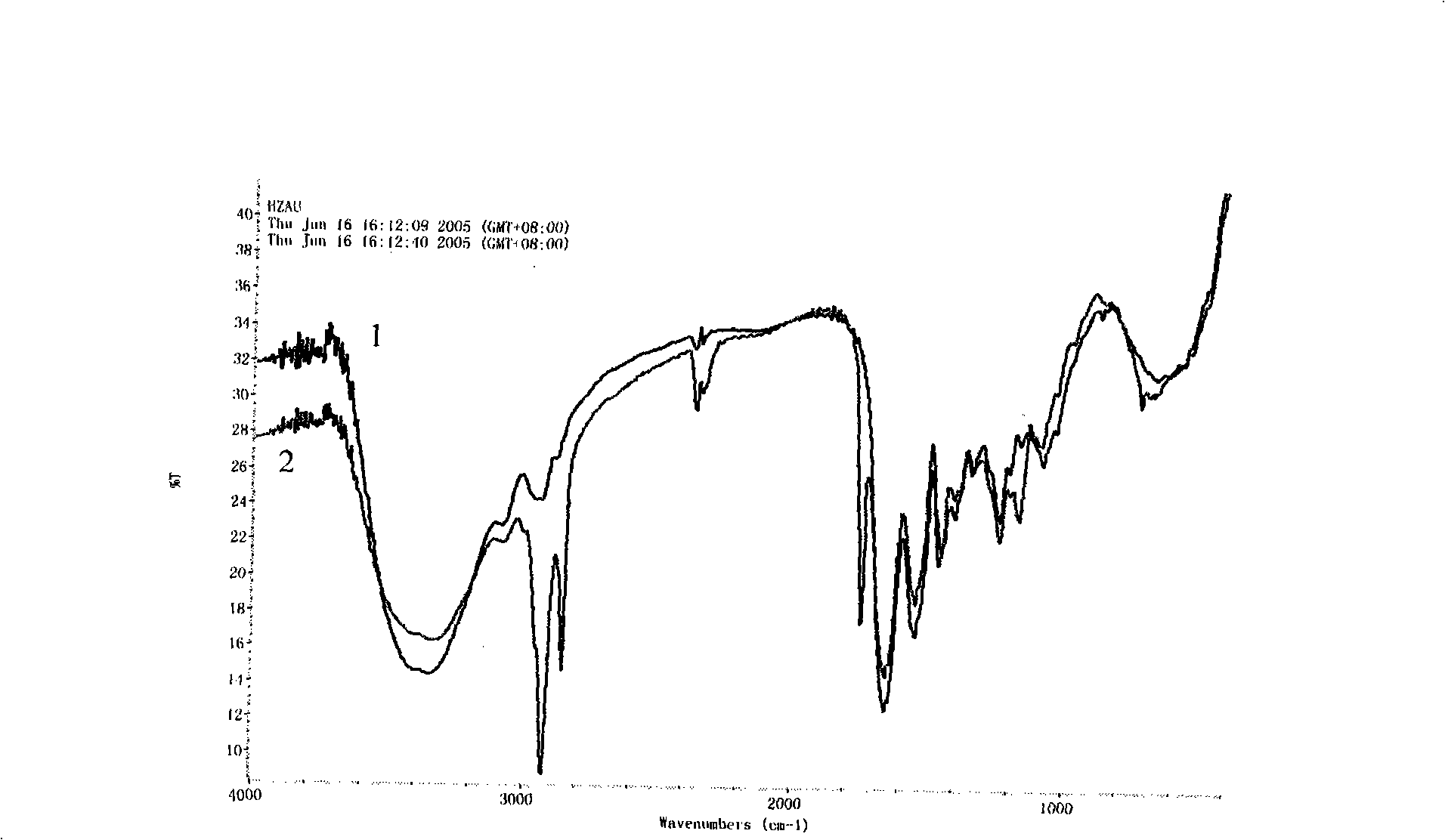

[0025]Add the washed fresh grass carp (commercially available) scales into clean tap water at a ratio of 1:10 (W / V), and use an electric stirrer (instrument model: JJ-200W, Huanyu Scientific Instrument Factory, Jintan City, Jiangsu Province) Stir intermittently below 20°C for 3 minutes (2500 rpm), wash the fish scales with clean tap water until no pigment and fat are attached to the surface. Naturally air-dried or dried at 40-50°C and crushed to 50 mesh. Weigh 100g of the pretreated raw material and add it into a 10% citric acid aqueous solution at a ratio of 1:10 (W / V), treat it with microwave (500W) in an ice-water bath for 1min (keep the system temperature below 20°C), and then remove it at 10°C. Calcium for 24 hours, filtered and separated to obtain decalcified fish scales and filtrate, and the obtained filtrate was placed at 4°C for 10 hours to obtain calcium citrate precipitation; to the obtained decalcified fish scales, add mass The concentration is 1% citric acid solu...

Embodiment 2

[0027] Add the cleaned fresh crucian carp (commercially available) scales into clean tap water at a ratio of 1:15 (W / V), and stir intermittently with an electric stirrer (instrument model: JJ-200W, Jiangsu Huanyu Scientific Instrument Factory) below 20°C 5 minutes (1500 rpm), wash with distilled water until the surface is free of pigment and fat. Naturally air-dried or dried at 50°C and crushed to 40 mesh. Weigh 100g of pretreated raw materials and add 8% malic acid aqueous solution at a ratio of 1:15 (W / V), treat with microwave (380W) in an ice-water bath for 2min (keep the system temperature below 20°C), and then heat at 15°C Decalcify for 20 hours, filter and separate the decalcified fish scales and filtrate, place the obtained filtrate at a temperature below 10°C for 8 hours, and obtain calcium citrate precipitation; Add a mass concentration of 1% malic acid solution (containing 1% pepsin, in terms of mass fraction) and extract at 15°C for 3 times, each time for 12 hours....

Embodiment 3

[0029] Add the cleaned grass carp (commercially available product) scales into clean tap water at a ratio of 1:12 (W / V), and use an electric stirrer (instrument model: JJ-200W, Jintan Huanyu Scientific Instrument Factory, Jiangsu Province) below 20°C. ) intermittently stirred for 2 minutes (3500 rpm), and washed with distilled water until no pigment and fat were attached to the surface. Naturally air-dried or dried at 50°C and crushed to 40 mesh. Weigh 100g of the pretreated raw material and add a 10% aqueous solution of citric acid at a ratio of 1:10 (W / V), treat it with microwave (100W) in an ice-water bath for 5min (keep the system temperature below 20°C), and then heat it at 10°C Decalcify for 24 hours, filter and separate the decalcified fish scales and filtrate, place the obtained filtrate at 4°C for 10 hours to obtain calcium citrate precipitate; add The mass concentration is 1% citric acid solution (the solution contains 1% alkaline protease, in terms of mass fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com