Metallurgy purification method for polysilicon

A purification method and polysilicon technology, which are applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve the problems of high energy consumption, environmental pollution, and low polysilicon purity, and achieve the effect of low energy consumption and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

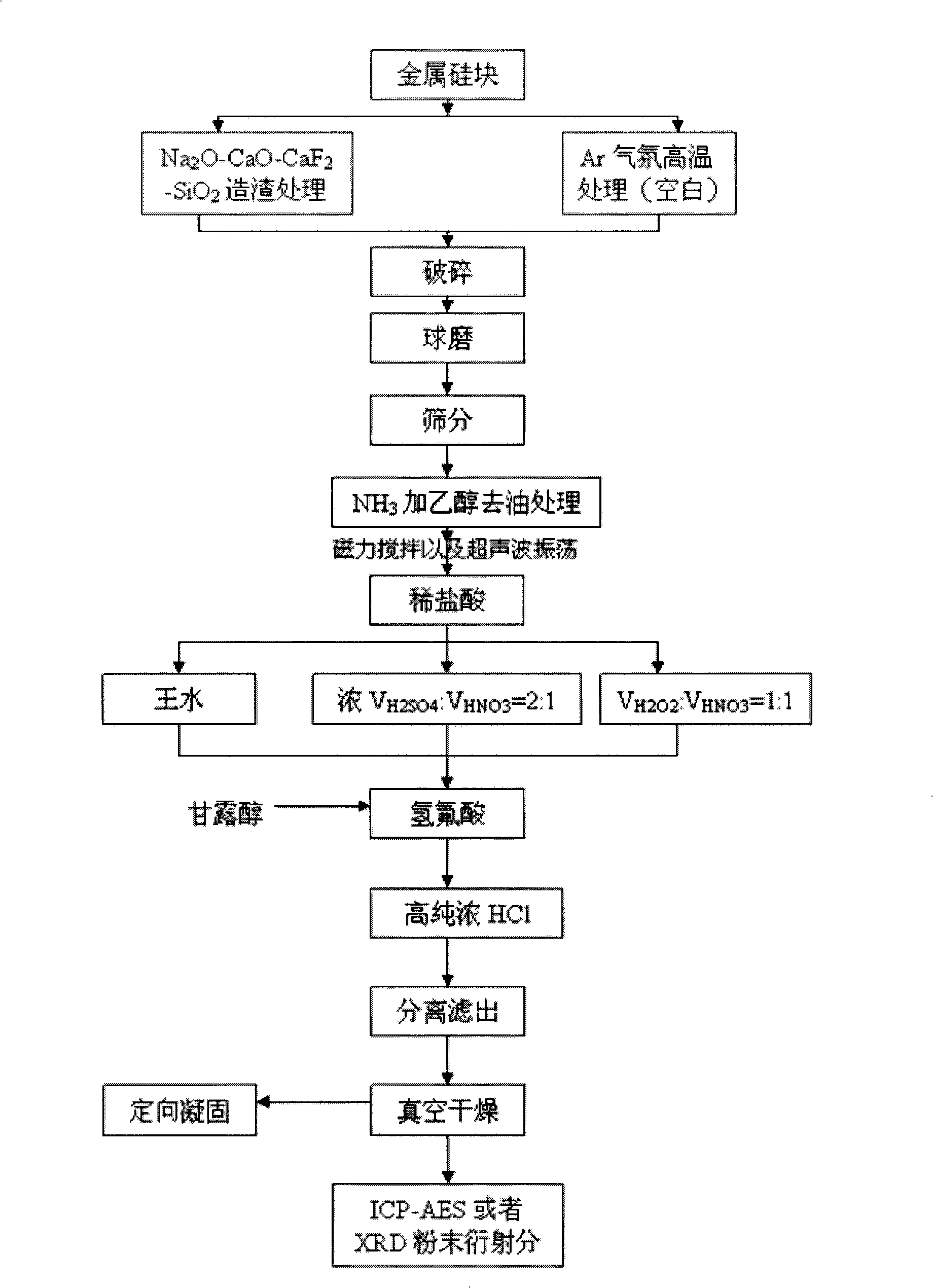

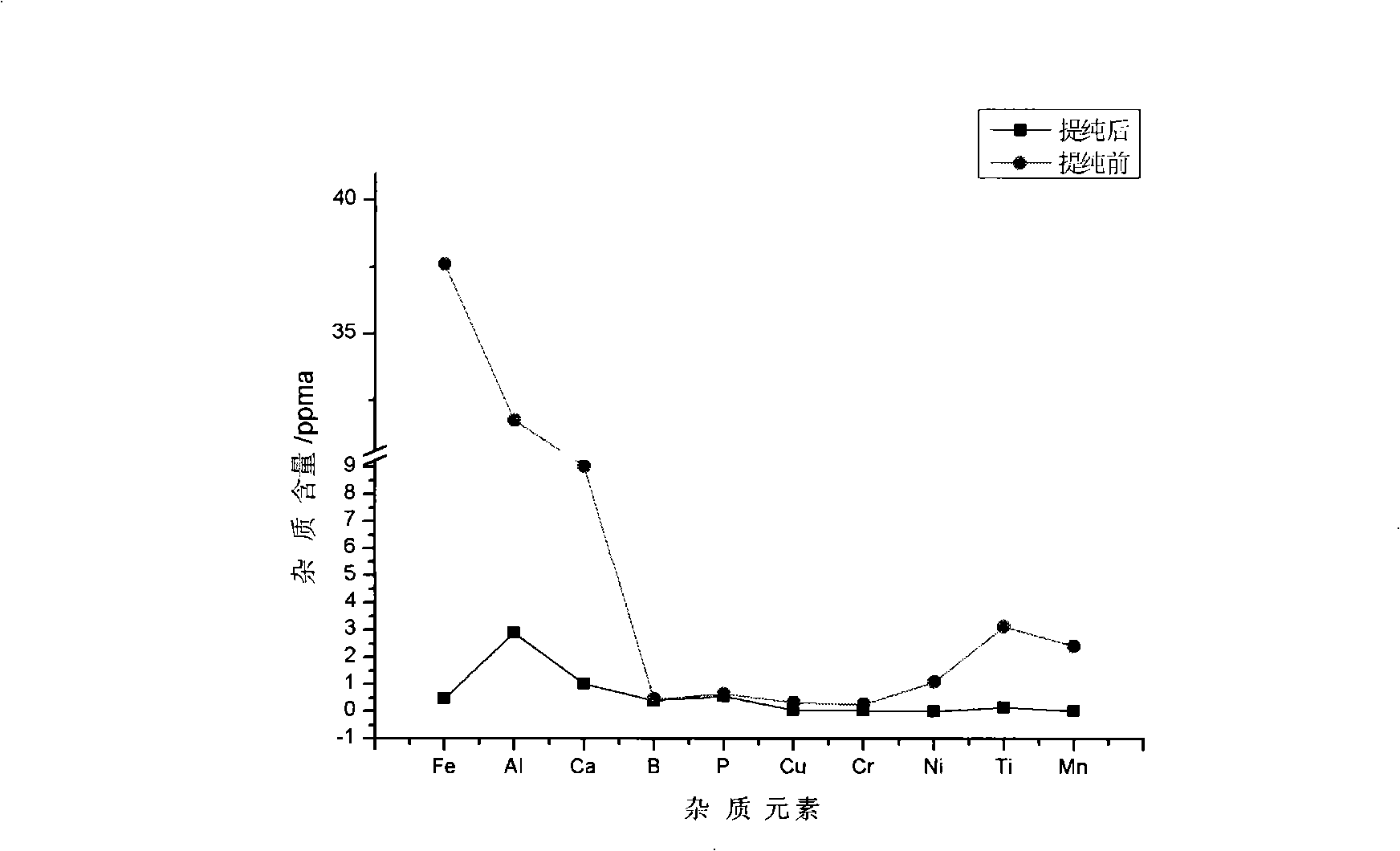

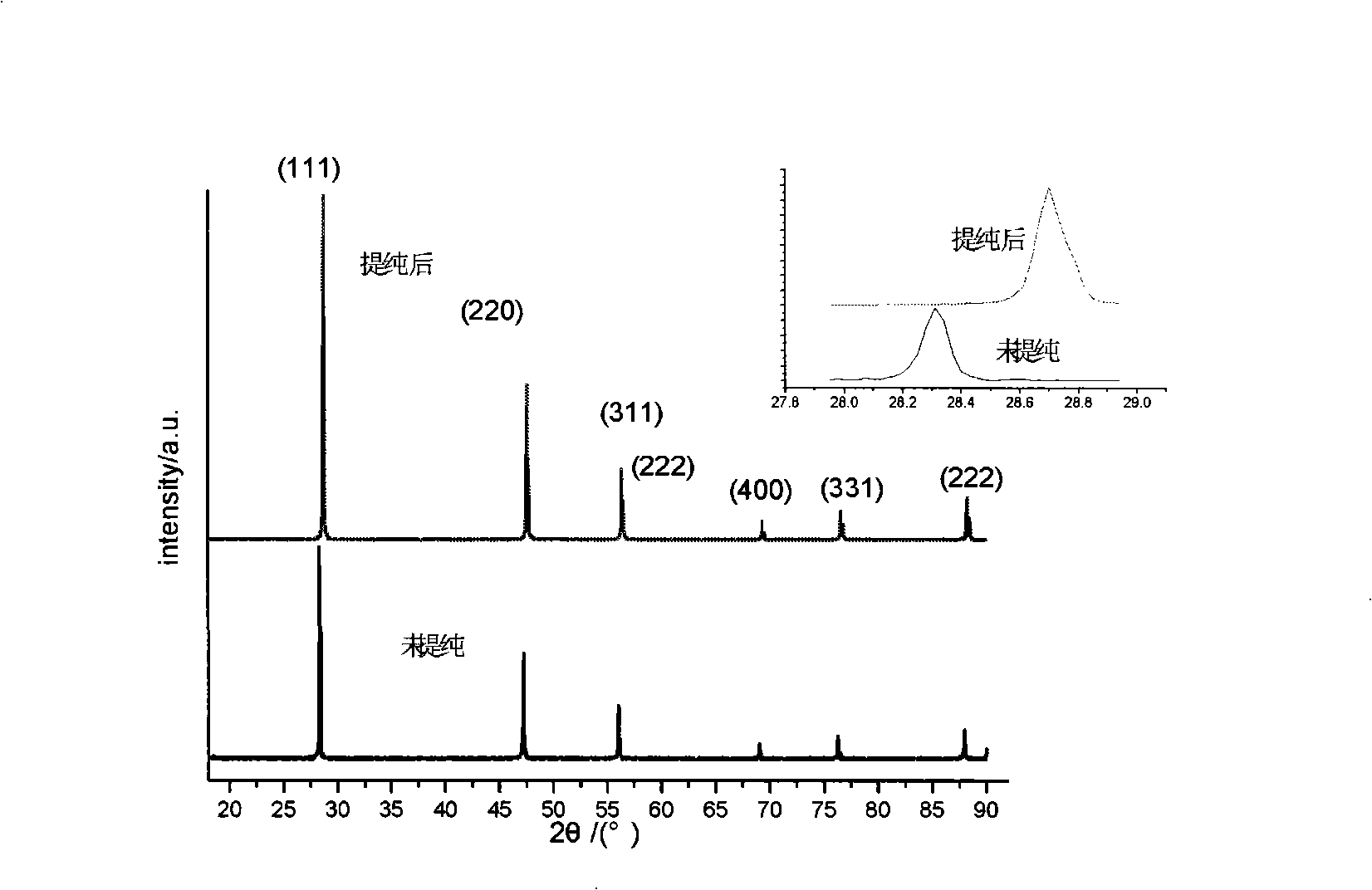

[0040] Break 10g of metal silicon block 441#, and add the alkaline slagging agent Na with a slag-gold ratio of 0.20 2 O-CaO-CaF 2 -SiO 2 (10:20:10:60), mixed evenly in a mortar, put into a medium-frequency induction resistance furnace with a power of 20KV and smelted under the protection of inert Ar gas. After heating up for 1 hour, keep warm at 1550°C for 30 minutes and cool down. The silicon ingots are crushed, ball milled and sieved to obtain 100-300 mesh products. Silica fume passed through 1% dilute ammonia water / H 2 o 2 Soak in the mixed solution and ethanol organic solvent for degreasing treatment, wash with deionized water and dry in an oven at 100°C. Under the condition of magnetic stirring, quickly pour 100 mL of HCl solution with a concentration of 1 mol / L into the dried silicon powder, leaching for 2 hours at a temperature of 60 ° C, and after washing with deionized water, add aqua regia and concentrated H 2 SO 4 : Concentrated HNO 3 (V:V=2:1) or concentr...

specific Embodiment 2

[0042] Break 10g of metal silicon block 441# into a medium-frequency induction resistance furnace with a power of 20KV and melt it under the protection of inert Ar gas. After heating up for 1 hour, keep warm at 1550°C for 30 minutes and cool down. The silicon ingots are crushed, ball milled and sieved to obtain 100-300 mesh products. Silica fume passed through 1% dilute ammonia water / H 2 o 2 Soak in the mixed solution and ethanol organic solvent for degreasing treatment, wash with deionized water and dry in an oven at 100°C. Under the condition of ultrasonic vibration, quickly pour 100 mL of HCl solution with a concentration of 1 mol / L into the dried silicon powder, leaching for 2 hours at a temperature of 60 ° C, and after cleaning with deionized water, add aqua regia and concentrated H 2 SO 4 : Concentrated HNO 3 (V:V=2:1) or concentrated HNO 3 :H 2 o 2 (V:V=1:1) 100mL, leached at 60°C for 2h, washed with deionized water, added 1mL of 2.5% mannitol solution for soa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com