Water dispersible magnetic high polymer microsphere and preparation thereof

A technology of polymer microspheres and magnetism, applied in the direction of magnetism of organic materials/organic magnetic materials, etc., can solve the problems of large difference in the magnetic strength of microspheres, incomplete magnetic centers embedded in polymers, and uneven magnetic content. , to achieve the effect of convenient storage, transportation and preservation, good monodispersity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

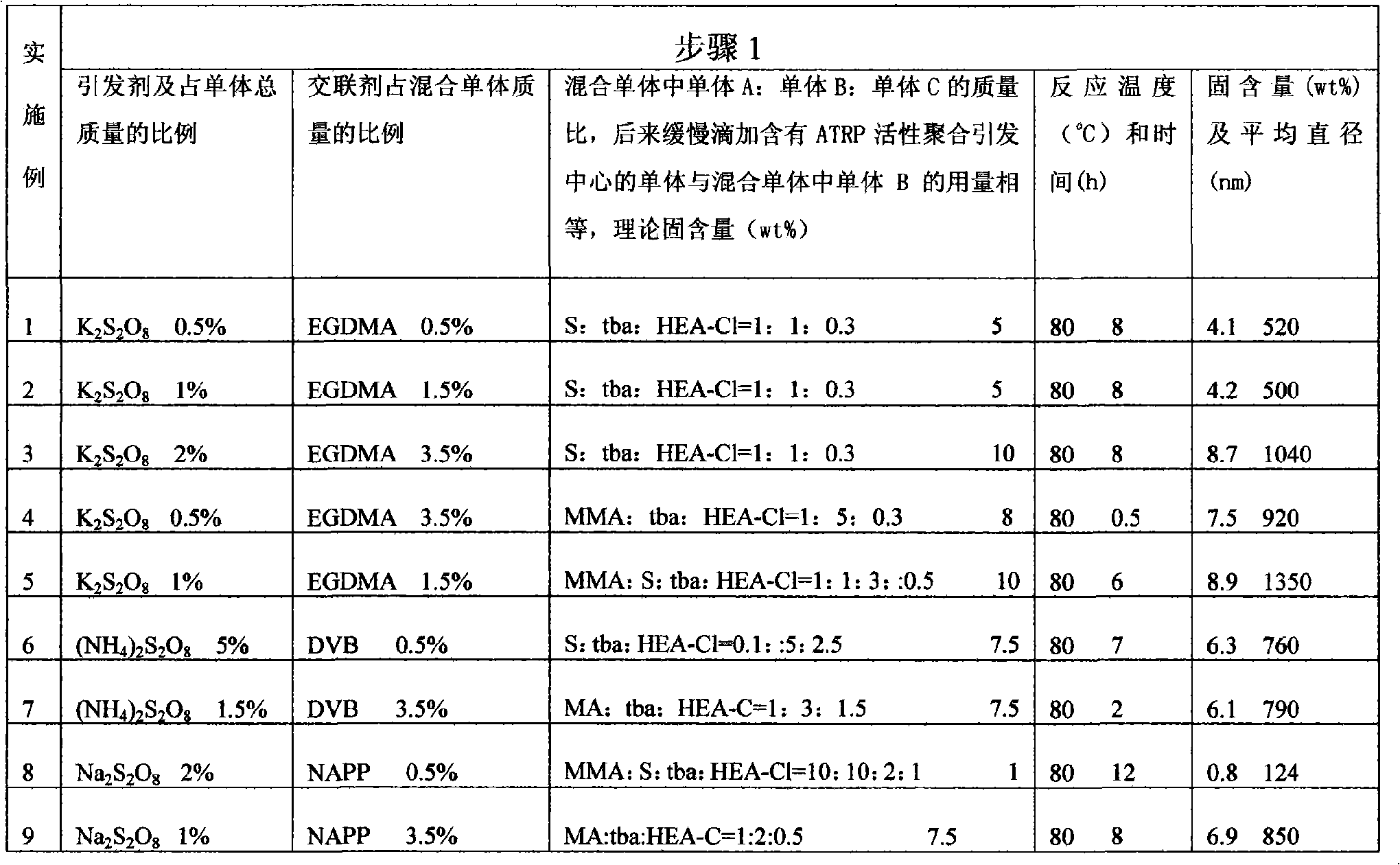

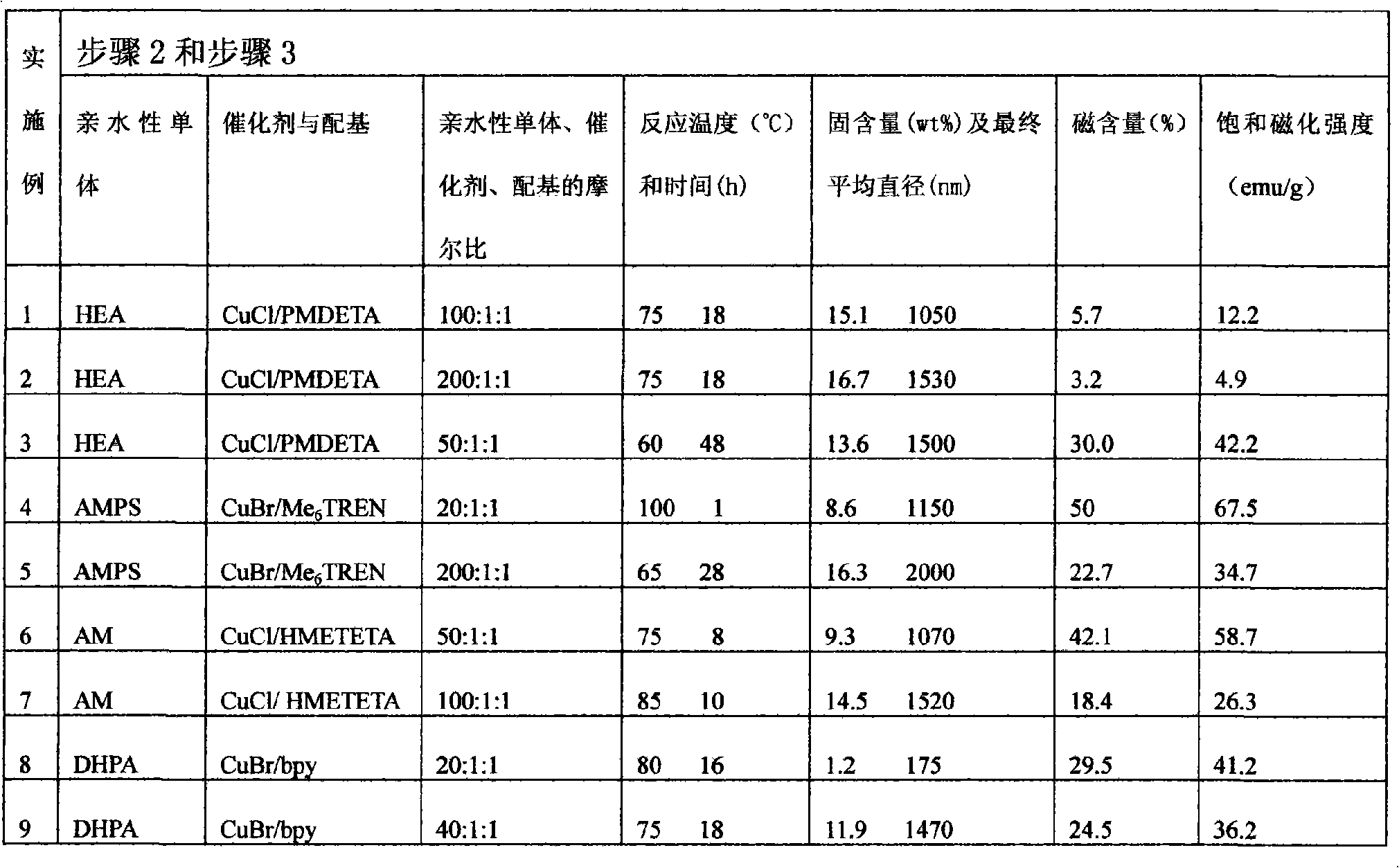

Examples

Embodiment 1

[0031] (1) Preparation of microsphere cores by soap-free emulsion polymerization and formation of active polymerization initiation centers

[0032] Dissolve 0.023g of potassium persulfate (KPS, 0.5% of the total mass of the monomer) into 95.5ml of water, add it to a four-necked flask, pass N2 gas for 10min, put it into an oil bath whose temperature has been adjusted to 83°C, and wait for After the system temperature was stabilized at 80°C, a mixture of styrene (1.73g), tert-butyl acrylate (1.73g), 2-chloropropionic acid ethylene glycol diester (0.52g) and crosslinking agent EGDMA 0.023g was added dropwise After 40 minutes of reaction, 2-chloropropionic acid ethylene glycol diester (0.52 g was added dropwise, the temperature was maintained, and the reaction was continued for 8 hours with stirring, the heating was stopped, and naturally cooled to room temperature under stirring. Centrifuged for 15 minutes, the rotating speed was 3000r / min, separated Afterwards, the emulsion was ...

Embodiment 2

[0038] (1) Preparation of microsphere cores by soap-free emulsion polymerization and formation of active polymerization initiation centers

[0039] Dissolve 0.045g potassium persulfate (KPS, 1% of the total mass of the monomer) into 95.5ml water, join in the four-necked flask, pass N 2 After airing for 10 minutes, put it into an oil bath whose temperature has been adjusted to 83°C. After the system temperature is stable at 80°C, add 1.73g of styrene, 1.73g of tert-butyl acrylate, and 2-chloropropionic acid ethylene glycol diester 0.52g and cross-linking agent EGDMA 0.068g (1.5% of the total monomer mass) of the mixed monomer 5min, after 40min of reaction, dropwise add 0.52g of 2-chloropropionic acid ethylene glycol diester, maintain the temperature, continue to stir the reaction 8h, stop heating, and naturally cool to room temperature under stirring. Centrifuge for 15min at a speed of 3000r / min, and take the emulsion after separation. Its solid content was measured to be 4.2...

Embodiment 3

[0045] (1) Preparation of microsphere cores by soap-free emulsion polymerization and formation of active polymerization initiation centers

[0046] Dissolve 0.09g (2% of the total monomer mass) of potassium persulfate into 90.7ml of water, add it to a four-necked flask, and pass N2 gas for 10 minutes, then put it into an oil bath whose temperature has been adjusted to 83°C. After stabilizing at 80°C, add dropwise a mixture of styrene 3.46g, tert-butyl acrylate 3.46g, 2-chloropropionic acid ethylene glycol diester 1.04g and crosslinking agent EGDMA 0.312g (3.5% of the total monomer mass) After 5 minutes of monomer reaction and 40 minutes of reaction, 1.04 g of 2-chloropropionic acid ethylene glycol diester was added dropwise, and the temperature was maintained. Stirring was continued for 8 hours. Heating was stopped, and the mixture was naturally cooled to room temperature while stirring. Centrifuge for 15min at a speed of 3000r / min, and take the emulsion after separation. Its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com