Homogeneous phase cation exchange film and preparation method thereof

A technology of cation exchange membrane and cross-linking agent, which is applied in the field of homogeneous cation exchange membrane and its preparation, can solve the problems of exchange capacity limitation, complicated steps, environmental pollution, etc., and achieves great adjustability, easy operation and shortened reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

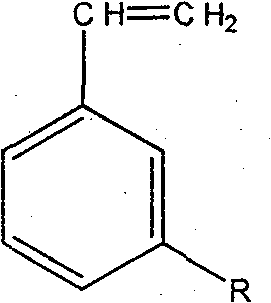

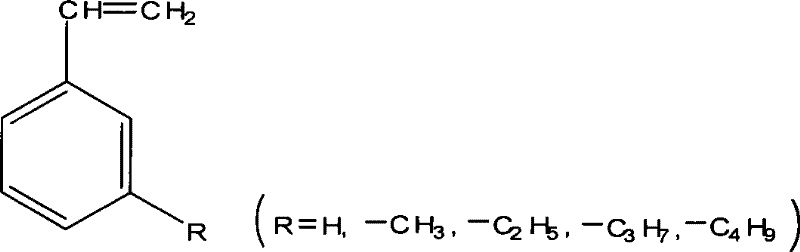

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 3g of methyl brominated polyphenylene ether at room temperature in 10ml of styrene and divinylbenzene in a mixed monomer with a volume ratio of 9.4:0.6 to obtain a homogeneous solution, then add 0.8g of benzoyl peroxide initiator, and obtain after completely dissolving Uniform coating solution; apply the coating solution on a polyvinyl chloride fabric with a thickness of 0.10mm, polymerize at 70-90°C for 6-8 hours to obtain a base film. Take out the basement membrane, sulfonate the basement membrane at 50°C for 1 hour in a mixed acid of concentrated sulfuric acid and chlorosulfonic acid at a volume ratio of 1:1, take out the sulfonated basement membrane, and sulfonate the basement membrane at 98%, 40%, Place in 20% and 5% sulfuric acid for 1 hour respectively, and then soak in 1mol / l NaCl solution for 24-48 hours to convert to Na form. Finally, take it out, wash and dry it with deionized water to obtain the Na-type cation exchange membrane.

[0024] Carry out ...

Embodiment 2

[0027] Using the same operating process as in Example 1, changing the amount of brominated polyphenylene ether to 1 g and the amount of initiator to 0.3 g, a film with a similar structure was obtained, and finally the cation exchange membrane prepared by this embodiment was measured The water content and ion exchange capacity are 22.0% and 1.6mmol / g-dry membrane, respectively, and the membrane resistance is 3.82Ω·cm 2 , the ion mobility number is 0.98. The above test data show that the membrane has good conductivity and high ion selectivity, and can be applied in the field of electrodialysis.

Embodiment 3

[0029] Using the same operation process as in Example 1, the amount of brominated polyphenylene ether was changed to 2g, and the amount of initiator was changed to 0.6g to obtain a membrane with a similar structure. Finally, the cation exchange membrane prepared in this example was measured. The water content and ion exchange capacity are 26.7% and 2.10mmol / g-dry membrane, respectively, and the membrane resistance is 2.78Ω·cm 2 , the ion mobility number is 0.99. The above test data show that the membrane has good conductivity and high ion selectivity, and can be applied in the field of electrodialysis.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

| transference number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com